High Hardness B80 Zirconia Ceramic Bead Blasting For Sandblasting Machine

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | Negotiable |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kgs Barrels+Pallet |

| Delivery Time: | 3-7 days |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 3000mts per year |

|

Detail Information |

|||

| Product Name: | Ceramic Bead Blasting Media | Model: | B20/B40/B60/B80/B100/B120/B150/B170/B205/B400/B505 |

|---|---|---|---|

| Color: | White | Main Chemicals: | 60-66% ZrO2 |

| True Density: | 3.85g/cm3 | Bulk Density: | 2.3 G/cm3 |

| Vicker Hardness: | 700HV | Usage: | Sand Blasting,cleaning, Polishing |

| Highlight: | High Hardness Ceramic Bead Blasting Media,B80 Zirconia Ceramic Bead Blasting Media,Ceramic Bead Blasting For Sandblasting Machine |

||

Product Description

1. Product Description of Ceramic Beads Blasting Media

Ceramic beads blasting media was made by zirconium silicate powder through a unique formula, special production process and pretreatment, then made by over 2000°C high temperature phase method. Especially it suitable for the shot blasting during the process of metal parts production and maintenance and peen forming of light alloy components.

2. Specification of Ceramic Beads Blasting Media

|

Product |

Process |

Specific Density |

Bulk Density |

|

Ceramic beads |

Electro-fusing |

3.85 (g/cm³) |

2.3 (g/cm³) |

|

Chemical Components |

ZrO2 62-68%,SiO2 25-30%,Al2O3 7-13%,Other 1% Max. |

||

|

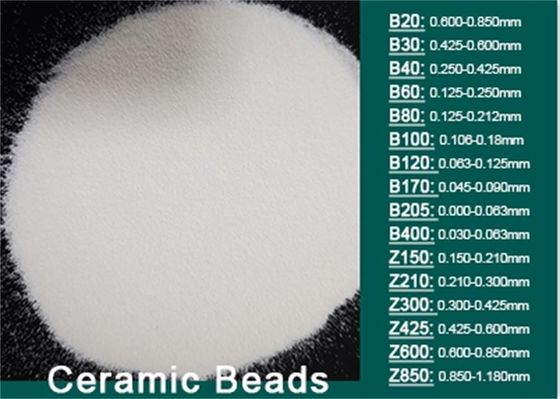

Size Available(mm) |

Blasting-clean/Surface finish |

Shot peening |

|

|

B20: 0.600-0.850mm |

Z150: 0.150-0.210mm, |

||

|

B30: 0.425-0.600mm |

Z210: 0.210-0.300mm |

||

|

B40: 0.250-0.425mm |

Z300: 0.300-0.425mm, |

||

|

B60: 0.125-0.250mm |

Z425: 0.425-0.600mm, |

||

|

B80: 0.180-0.250mm |

Z600: 0.600-0.850mm |

||

|

B100: 0.128-0.18mm |

Z850:0.850-1.180mm |

||

|

B120: 0.063-0.125mm |

Size can be customized |

||

|

B170: 0.045-0.090mm |

|||

|

B205 : 0.000-0.063mm |

|||

|

B400: 0.000-0.063mm |

|||

3. Main Features of Ceramic Beads Blasting Media

1) White color, high sphericity and smooth surface beads.

2)High hardness and toughness, strong mechanical resistance, but gentle with equipment and tools preserving work parts.

3) Less operating pressure and reduced abrasive velocity needed. So it has far less abrasive breakdown and dust generation for cleaner working environment.

4) Chemically inert, no metallic contamination for treated parts.

4. Application of Ceramic Beads Blasting Media

Ceramic beads blasting media can be used in these applications (just name a few):

1)Cleaning and surface preparation (deburring, etching, paint removal and cosmetic finishing ) of moulds, castings and delicate items.

2)Effectively used in air or wet pressure blasting process and in wheel turbine machines.

![]()

5. Storage, Package and Usage of Ceramic Beads

Ceramic beads should be stored in a dry, clean and ventilated indoor environment;

Masks and protective suit should be worn when using ceramic beads;

Normal package:25kg round barrel+pallet;

When using ceramic beads at the first time, open 1/3 to 1/2 vest of dust collector,because ceramic beads need the wind to be recycled in the blasting process.