B40 0.250 - 0.425mm Zirconia Ceramic Bead Blasting Media B60 For Matte Finish

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiable |

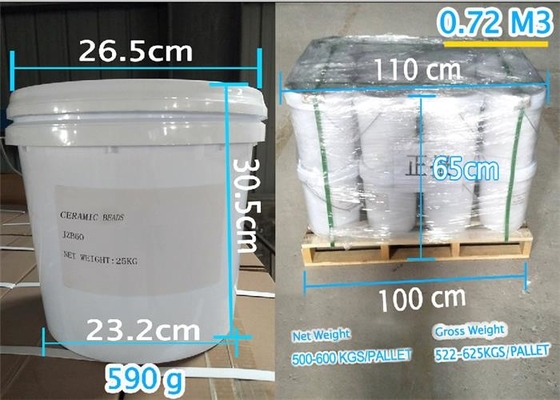

| Packaging Details: | 25kg barrel+pallet or 25kg barrel + Woodencase |

| Delivery Time: | Within 3-5 days after order Confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 3000 MTS Per Year |

|

Detail Information |

|||

| Commodity: | Ceramic Beads | Product Name: | Ceramic Blasting Media |

|---|---|---|---|

| Bulk Density: | 2.3 G/cm3 | True Gravity: | 3.85 G/cm3 |

| Particle Range: | 0-850 μm | Specification: | B20-B505 |

| Vicker Hardness: | 700HV | Sphericity: | ≥ 80% |

| Highlight: | Matte Finish Ceramic Bead Blasting Media,0.425 mm Ceramic Bead Blasting Media,B60 Zirconia Ceramic Bead Blasting Media |

||

Product Description

Zirconia Ceramic Bead Blasting Media B40(0.250-0.425mm) B60 (0.125-0.250mm) for Matte Finish

1. Product Description of Ceramic Blasting Media

Ceramic beads is one white solid beads, mainly used for glass bottle mold cleaning and tire mold cleaning

at the initial stage,then gradually applied to the stainless steel parts in machinery, chemical, petroleum

industries.

It selects the high-quality imported zircon sand as the main raw material,then fused in one arc furnace

and finally made into different beads by special technology.

The main component of ceramic beads is 60-66% ZrO2, 25-30% SiO2 and 7-13% Al2O3. Its chemical

composition and dense crystal structure, determines its outstanding characteristics of high hardness,

good strength, low break-down rate and little dust generated in the whole blasting process. It is an green

and efficient blasting media.

2. Main Product Data of Ceramic Beads

| Commodity Name | Ceramic Beads Blasting Media | |

| Chemical Index | ZrO2 | 60-66% |

| SiO2 | 25-30% | |

| Al2O3 | 7-13% | |

| Physical Index | Vickers Hardness | ≥700HV |

| Bulk Density | ≥2.3g/cm3 | |

| True Gravity | ≥3.85g/cm3 | |

| Ceramic Blasting Media | B20: 0.600-0.850mm | B120:0.063-0.125mm |

| B30:0.425-0.600mm | B150:0.000-0.125mm | |

| B40:0.250-0.425mm | B170:0.045-0.090mm | |

| B60:0.150-0.300mm | B205:0.000-0.063mm | |

| B80:0.125-0.212mm | B400:0.030-0.063mm | |

| B100:0.106-0.180mm | B505:0.010-0.030mm | |

| Ceramic Shot Peening | Z100: 100-150μm | Z150: 150-210μm |

| Z210: 210-300μm | Z300: 300-425μm | |

| Z425:425-600μm | Z600: 600-850μm | |

| Z850: 850-1180μm | / | |

| Remark: Special specification can be customized. | ||

3 Main Applications of Ceramic Beads Blasting Media

For blasting purpose:

Surface Cleaning: glass-bottle molds cleaning,tire molds cleaning

Surface Finishing:3C products and its accessories

Surface Pretreatment: pretreatment before anodizing,electroplating

Surface Deburring: deburring for circuit board,heat treated parts

For shot peening purpose:

Surface Strengthening:Aircraft parts and engines

![]()

4. How to judge the quality of ceramic beads?

Particle size distribution

The particle size of ceramic beads directly affects the final roughness, meanwhile, the width of particle

size distribution also affects the stability of roughness. The narrower the particle size distribution is, the

more uniform the beads are.

Sphericity

The better the sphericity, the higher the glossiness of the blasted surface will be achieved.

Chemical Composition

ZrO2 is the main bearing body in the impact process of sandblasting or shotpeening,Its good toughness

and impact resistance ensure the integrity of the shape of the shot, so the chemical composition is closely

related to the service life of the shot and the surface treatment effect

Consumption

To test the service life of beads by pneumatic sandblasting crushing test or directly evaluate the normal

consumption in one certain period on the customer's equipment.

5. Why choose us?

Professional manufacturer of ceramic beads

Advanced production line, professional technical staffs, strict quality control system

Quick response and quick delivery

Flexible business mode and payment term

Stable supplier of Foxconn,samsung...