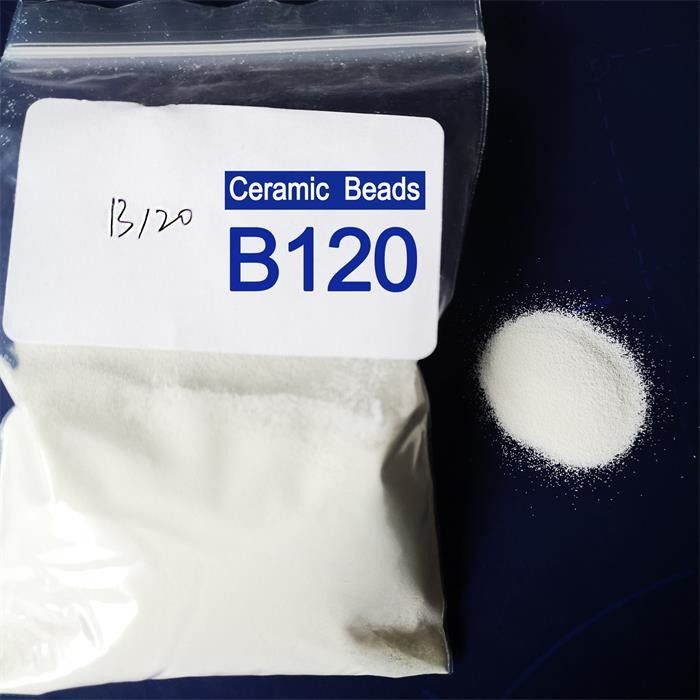

B120 Ceramic Bead Blasting For Pretreatment Before Coating By Wet Blasting

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kg barrel+pallet or 2*12.5kg barrel+ paper carton box + pallet |

| Delivery Time: | 3-5 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 200mts per month |

|

Detail Information |

|||

| Main Material: | 60-66% ZrO2 | Usage: | Open Sandblasting Machine |

|---|---|---|---|

| Commodity: | Ceramic Beads | Product Name: | Ceramic Blasting Media |

| Bulk Density: | 2.3 G/cm3 | True Gravity: | 3.85 G/cm3 |

| Vicker Hardness: | 700HV | Shape: | Solid Round Ball |

| Highlight: | B120 Ceramic Bead Blasting,Pretreatment Ceramic Bead Blasting,B120 ceramic blasting beads |

||

Product Description

Ceramic blast media B120 for pretreatment before coating by wet blasting

- DESCRIPTION

ceramic blast media is often used for blast cleaning and pretreatment before coating on the surface of metal workpieces.

Sandblasting pretreatment can combine surface cleaning and finishing.The surface roughness and blasting effect will be different by controlling the particle size of the ceramic blast media, the speed of the abrasive flow, the angle of the blasting gun, the distance to the workpiece, the pressure of the blasting gun, etc.,

Pretreatment before coating by sandblasting is a thorough surface treatment method. Due to the impact of ceramic abrasive particles, the surface area of the metal will be increased tenfold. This increases the surface to which the paint, coating or plating adheres.

![]()

- SPECIFICATION

|

Chemical & Physical Index

|

||||||

| Chemical Index | Production Process | True Density | Bulk Density | Hardness | ||

| Vickers | Mohs | Rockwell | ||||

|

ZrO2 : 60-66% SiO2: 25-30% Al2O3: 7-13% |

Smelting | 3.85 | 2.3 | 700HV | 7 | 60HRC |

|

|

||||||

|

Sizes

|

||||||

|

B20: 0.600-0.850mm |

B80: 0.125-0.212mm | B170: 0.045-0.090mm | ||||

|

B30: 0.425-0.600mm |

B100: 0.106-0.180mm | B205:0.000-0.063mm | ||||

|

B40: 0.250-0.425mm |

B120: 0.063-0.125mm | B400: 0.030-0.063mm | ||||

|

B60: 0.150-0.300mm |

B150: 0.053-0.106mm | B505: 0.010-0.063mm | ||||

- APPLICATION

When ceramic blast media is used for sandblasting pretreatment, wet sandblasting is a better choice, which is safer, environmentally friendly and convenient.

Wet blasting, also known as vapour blasting, is a method of blasting that removes old coatings, paint, and other contaminants from the surface. Wet blasting mixes water with ceramic blast media.

It's more safe and dust-free. During dry blasting, when ceramic blast media particles hit the blasting material, they may break. When electrostatically charged particles are broken during dry spraying, they will produce sparks.

Adding water makes the blasting operator and the substrate safer. The water diffuses and eliminates the dust generated in the process.

The ceramic blast media has a uniform texture, and the water also increases the weight of the ceramic blast media particles, removing contaminants and coatings more effectively, leaving a more uniform and softer finish without damaging the underlying materials.

- CONTACT US

Besides the ceramic blast media, we also have other blast media abrasive like glass beads, steel shot, and aluminium oxide grits, PA nylon sand, PC frozen sand, etc. Please feel free to send inquiry to us. All inquiries will be replied soon within 24 hours in working time.