High Impact Resistance Ceramic Beads For Metal Blast Cleaning 125μM Easy To Clean

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

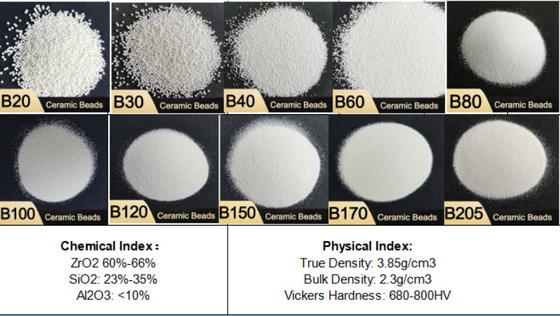

| Model Number: | B20-B205 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 12.5kgs/barrel, 25kgs (2 barrels)/paper carton, or 25kgs barrels +pallet |

| Delivery Time: | 5-10 days |

| Supply Ability: | 1500mt per year |

|

Detail Information |

|||

| Commodity Name: | Ceramic Beads Blasting Media | Chemical Index: | ZrO2 60-66%, SiO2 25-30%, Al2O3 7-13% |

|---|---|---|---|

| Manufacturing Process: | Melting Method | Bulk Density: | 2.3g.cm3 |

| True Density: | 3.85g/cm3 | Hardness: | 700HV |

| Package: | 25kgs Paper Cartons Or 25kgs Barrels +pallet | ||

| Highlight: | High Impact Resistance Ceramic Beads Blasting,125μm Ceramic Beads Blasting Media,Ceramic Beads For Metal Blast Cleaning |

||

Product Description

Ceramic beads for metal blast cleaning B150 size 63-125 μm easy to clean

1. DESCRIPTION

Ceramic beads blasting media is made of zircon sand raw material by electrofusion method, and its unique internal crystal phase structure ensures its strong hardness and impact resistance. Spherical bodies with perfectly smooth surfaces and dust-free characteristics provide the prerequisites for a good working environment. At the same time, the stable chemical inertness ensures that the workpieces being processed will not be contaminated.

Ceramic beads is widely used for metal surface sandblast cleaning.

2.SPECIFICATION

Manufacturing process: Melting method

| ZrO2 | SiO2 | Al2O3 | Other |

| 60-66%, | 25-30% max. | 7-13% max. | 5-8% |

| Color | Bulk Density | True Specific Density | Vickers Hardness |

| White | 2.3g/cm3 | 3.85g/cm3 | 700 HV |

| Grit size | B20 | B30 | B40 | B60 | B80 | B100 | B120 |

| Microns μm | 600-850 | 425-600 | 250-425 | 125-250 | 180-250 | 125-180 | 63-125 |

| Grit size | B150 | B170 | B205 | B400 | B505 |

Special sizes can be customized |

|

| Microns μm | 53-106 | 45-90 | 0-63 | 30-63 | 0-63 | ||

| Grit size | Z850 | Z600 | Z425 | Z300 | Z210 | Z150 | Z100 |

| Microns | 850-1180 | 600-850 | 425-600 | 300-425 | 210-300 | 150-210 | 100-150 |

3. FEATURES

(1) Does not contaminate the metal surface of parts;

(2) After the treatment, the quality of the components is uniform and stable, and the service life is significantly prolonged;

(3) The specific gravity is light, the sphericity is high, and the parts are never damaged;

(4) Low loss, long service life, and consumption is more than 80% lower than that of glass beads;

(5) Reduce dust, improve working environment, reduce energy consumption and operating costs.

4. APPLICATION

Blast Cleaning of metal workpiece surface

Ceramic beads can be used as blasting abrasive media to remove:

Rust layer on the metal surface;

Residual salt and oxide layer on the surface of heat-treated parts;

Molding sand and oxide layer on the surface of castings;

Oxide layer on the surface of forging parts;

Welding seam on the welding parts;

Dirt and tiny burrs and residual on the surface of machining parts.

Refurbishment of old metal parts, etc.

Removing the surface adhesion layer and reveal the true color of the metal. The surface cleaning quality can be avenue Sa3.

![]()

5. PACKAGE

25 kg barrels on pallets, 500-1000kgs per pallet

Contact us to upgrade your sandblasting process.