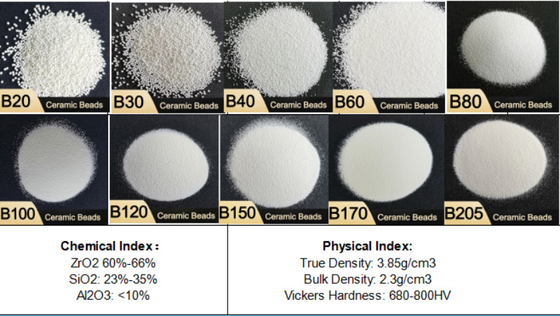

High Hardness Ceramic Beads Blasting Finish Media B30 Round Beads

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B205 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 12.5kgs/barrel, 25kgs (2 barrels)/paper carton, or 25kgs barrels +pallet |

| Delivery Time: | 5-10 days |

| Supply Ability: | 1500mt per year |

|

Detail Information |

|||

| Commodity Name: | Ceramic Beads Blasting Media | Chemical Index: | ZrO2 60-66%, SiO2 25-30%, Al2O3 7-13% |

|---|---|---|---|

| Manufacturing Process: | Melting Method | Bulk Density: | 2.3g.cm3 |

| True Density: | 3.85g/cm3 | Hardness: | 700HV |

| Package: | 25kgs Paper Cartons Or 25kgs Barrels +pallet | ||

| Highlight: | Ceramic Beads Blasting Finish Media,Ceramic Round Beads Blasting Media,High Hardness Ceramic Beads Blasting |

||

Product Description

Ceramic beads blasting finish B20,B30, B40, B60, B80, B100, B120, B150, B170, B205

1. DESCRIPTION

Ceramic beads is made of imported zircon sand as the main raw material, and is produced by high temperature smelting above 2000 degrees. Particularly suitable for metal blast cleaning, surface finishing and pretreatment before coating.

Ceramic beads has a fine microstructure, so it has very good impact strength and toughness, high hardness and surface smoothness, can be recycled repeatedly, and has a high utilization rate, which is 15-20 times that of glass beads.

B20-B505 has a wide range of particle sizes, strong optionality, and can be matched with various types of sandblasting machines.

2.SPECIFICATION

Manufacturing process: Melting method

| ZrO2 | SiO2 | Al2O3 | Other |

| 60-66%, | 25-30% max. | 7-13% max. | 5-8% |

| Color | Bulk Density | True Specific Density | Vickers Hardness |

| White | 2.3g/cm3 | 3.85g/cm3 | 700 HV |

| Grit size | B20 | B30 | B40 | B60 | B80 | B100 | B120 |

| Microns μm | 600-850 | 425-600 | 250-425 | 125-250 | 180-250 | 125-180 | 63-125 |

| Grit size | B125 | B170 | B205 | B400 | B505 |

Special sizes can be customized |

|

| Microns μm | 0-125 | 45-90 | 0-63 | 30-63 | 0-63 | ||

| Grit size | Z850 | Z600 | Z425 | Z300 | Z210 | Z150 | Z100 |

| Microns | 850-1180 | 600-850 | 425-600 | 300-425 | 210-300 | 150-210 | 100-150 |

3. FEATURES

- High impact resistance and round beads, not easy to be broken. The broken rate of ceramic beads is around 1%.

- Low dust generation, friendly to the environment and worker’s health.

- Matte Metallic luster, no polishing reflective.

- No metal pollution.

4. APPLICABLE BLASTING SYSTEMS

Pressure blast systems

Injection blast cabinets

5. APPLICATION

Surface finishing:

Achieve smooth but non-reflective matte visuals effects

Blast-cleaning:

-

Deburring of machined parts;

-

Removing scales from castings, forgings and heat treated parts;

-

Removing mould residues from castings;

-

Removing tempering colour;

-

Clean up welds

Pretreatment before Coating:

Achievie surface roughness to improve the bonding force

![]()

Applicable metals

- Aluminium

- Aluminium alloy

- Copper

- Steel

- Stainless steel

- Titanium Alloy

- Magnesium Alloy

- Zinc Alloy

6. PACKAGE

25 kg barrels on pallets, 500-1000kgs per pallet

Contact us to upgrade your sandblasting process.