B30 Ceramic Bead Blasting Media Size 0.425 - 0.600mm For Sandblasting Cleaning

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B30: 0.425-0.600MM |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kg barrel+pallet or 2*12.5kg barrel+ paper carton box + pallet |

| Delivery Time: | 3-5 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 200mts per month |

|

Detail Information |

|||

| Main Material: | 60-66% ZrO2 | Usage: | Sandblasting Machine |

|---|---|---|---|

| Commodity: | Ceramic Beads | Product Name: | Ceramic Blasting Media |

| Bulk Density: | 2.3 G/cm3 | True Gravity: | 3.85 G/cm3 |

| Vicker Hardness: | 700 HV | Shape: | Solid Round Ball |

| Highlight: | zirblast ceramic blasting media,0.6mm Ceramic Bead Blasting Media,ZrO2 ceramic bead abrasive |

||

Product Description

Ceramic blasting media B30 size 0.425-0.600mm for sandblasting cleaning

Description of ceramic blasting media

Ceramic beads is made of zircon sand as the main raw material, then smelted and sprayed into micorbeads at a high temperature over 2000 degrees. It is especially suitable for sandblasting cleaning of various metal workpieces. Ceramic beads has very good impact strength and toughness, high hardness and surface smoothness,and can be recycled repeatedly, 15-20 times of glass beads.

It has a wide range of particle size, strong optionality, and can be matched with various types of sandblasting machines.

Specification of ceramic blasting media

|

Chemical & Physical Index |

||||||

| Chemical Index | Production Process | True Density |

Bulk Density |

Hardness | ||

| Vickers | Mohs | |||||

|

ZrO2 : 60-66% SiO2: 25-30% Al2O3: 7-13% |

Smelting | 3.85 | 2.3 | 700HV | 7 | |

|

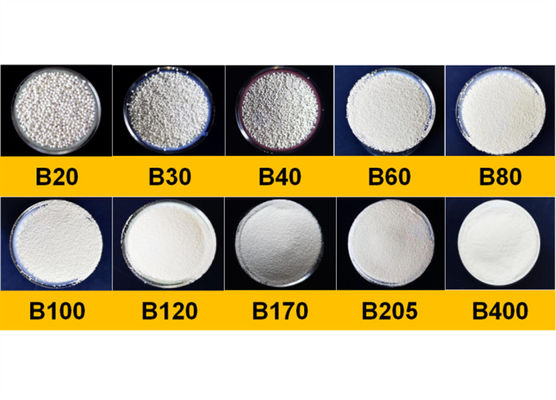

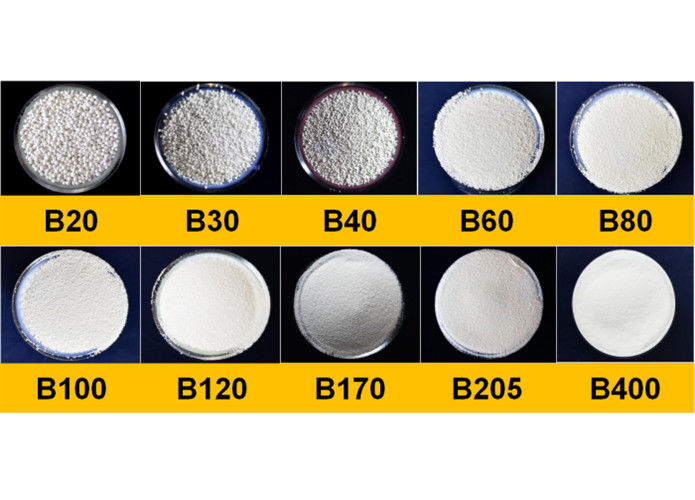

Sizes |

||||||

|

B20: 0.600-0.850mm |

B80: 0.125-0.212mm | B170: 0.045-0.090mm | ||||

|

B30: 0.425-0.600mm |

B100: 0.106-0.180mm | B205:0.000-0.063mm | ||||

|

B40: 0.250-0.425mm |

B120: 0.063-0.125mm | B400: 0.030-0.063mm | ||||

|

B60: 0.125-0.250mm |

B150: 0.053-0.106mm | B505: 0.010-0.063mm | ||||

Features of ceramic blasting media

1. The ceramic beads has good blasting effect, the surface treatment is smooth and uniform, and it has high consistency.

2. Good toughness, not easy to break, can be recycled repeatedly, long service life, reduce energy consumption and reduce costs.

3. It will not cause pollution to the processed parts or products.

4. Reduce dust, increase the service life of the equipment and improve the working environment.

5. Ceramic beads has an effective cutting effect, and is especially suitable for sandblasting on thin metal surfaces without bending or deformation.

Sandblasting cleaning is divided into four levels:

Sa1 level is also called manual scrubbing and cleaning level. (Or cleaning level)

Sa2 level is also called commodity cleaning level (or industrial level).

Sa2.5 level is also called near-white cleaning level (near-white level or out-white level).

Sa3 level white cleaning level (or white level)

You can choose the suitable abrasive according to your desired cleanup result.