25KG Wet Or Dry Airblast Ceramic Bead Blasting B20 B30 B40 Metal Surface Finish

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | By negotation |

| Packaging Details: | 25kg barrel+ Pallet or 2*12.5kg barrel+Carton+Pallet |

| Delivery Time: | 3-5 days after order confirmed |

| Payment Terms: | L/C, , D/P, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability: | 3000 mts per year |

|

Detail Information |

|||

| Commodity: | Ceramic Blasting Media | Product Name: | Ceramic Beads,Zirconium Oxide Beads |

|---|---|---|---|

| Usage: | Blasting Media,Surface Treatment | Color: | White |

| Material: | ZrO2 60-66%,SiO2 25-30%,Al2O3 7-13% | Hardness: | 700HV |

| Bulk Density: | 2.3g/cm3 | True Gravity: | 3.85g/cm3 |

| Specification: | B20-B505 | ||

| Highlight: | Ceramic Bead Blasting B20,Ceramic Bead Blasting B30,Surface Finish Ceramic Bead Blasting |

||

Product Description

25KG Wet or Dry Airblast Ceramic Bead Blasting B20 B30 B40 for Metal Surface Finish

1. Product Description of Ceramic Beads

Ceramic beads is one clean and high efficient blasting media,it selects the high quality imported zircon

sand as main material,then fused in high temperateure over 2500 degrees, finally made into different

microbeads.

The unique crystal structure of ceramic beads ensures its high hardness and good impact resistance,

its smooth surface and stable chemical inertness ensures little damage to the blasting machine and

zero contamination to the treated workpieces.

Ceramic beads has lower break-down rate,which will improve the blasting efficiency and easy to achieve

one more consistent and shinny blasting effect.

So ceramic beads is widely used in blasting application,especially suitable for metal surface finish.

2. Main Technical Data of Ceramic Bead Blasting

| Commodity Name | Ceramic Bead Blasting | |

| Chemical Index | ZrO2 | 60-66% |

| SiO2 | 25-30% | |

| Al2O3 | 7-13% | |

| Physical Index | Vickers Hardness | ≥700HV |

| Bulk Density | ≥2.3g/cm3 | |

| True Gravity | ≥3.85g/cm3 | |

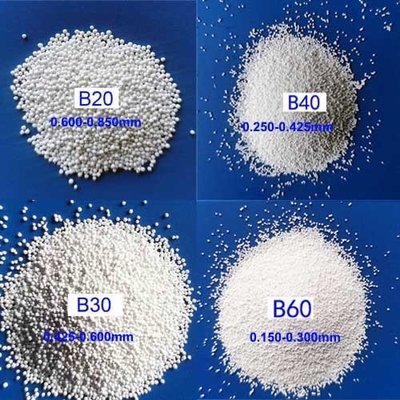

| Ceramic Blasting Media | B20: 0.600-0.850mm | B120:0.063-0.125mm |

| B30:0.425-0.600mm | B150:0.000-0.125mm | |

| B40:0.250-0.425mm | B170:0.045-0.090mm | |

| B60:0.150-0.300mm | B205:0.000-0.063mm | |

| B80:0.125-0.212mm | B400:0.030-0.063mm | |

| B100:0.106-0.180mm | B505:0.010-0.030mm | |

| Ceramic Shot Peening | Z100: 100-150μm | Z150: 150-210μm |

| Z210: 210-300μm | Z300: 300-425μm | |

| Z425:425-600μm | Z600: 600-850μm | |

| Z850: 850-1180μm | / | |

| Remark: Special specification can be customized. | ||

3. Main Applications of Ceramic Bead Blasting

Surface cleaning for the inner and outer walls of stainless steel pipes;

Surface preparation before electroplating,anodizing to achieve one certain roughness,then improve the

surface adhesion;

Surface finish for light alloy such as magnesium alloy,aluminium alloy, titanium alloy to restore the metal

color;

Surface cleaning for electronic parts,heat-treated parts,welded parts to remove the surface burrs and weld

joint;

Shot peening for aviation and automotive industries such as aircraft landing gear and automotive gears to

eliminate the stress and improve the fatigue strength and service life.

![]()

4. How to judge the quality of ceramic beads?

Seen from the appearance,good ceramic beads has higher sphericity,mostly beads is in round shape, little in strip

shape,which is visible by naked eyes.

Seen from the gloss under the microscope, good ceramic beads has good shinny gloss.

Judge from the cleanliness,good ceramic beads can quickly sink into the bottom of the container,while the water is still clear.

5. Main Package of Ceramic Beads

25kg round barrel+Pallet

2*12.5kg barrel+Carton + Pallet

25kg round barrel+ Pallet

Special package can be customized.