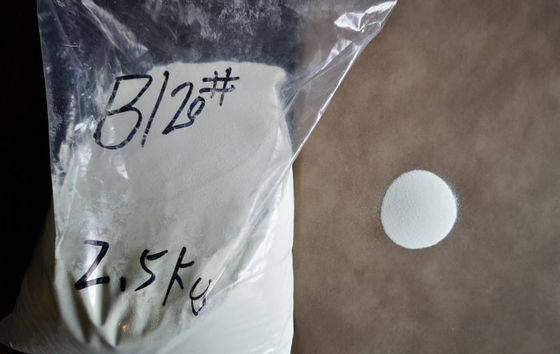

ISO ZrO2 B120 Metal Surface Finishing Ceramic Beads

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kg barrel+pallet or 2*12.5kg barrel+ paper carton box + pallet |

| Delivery Time: | 3-5 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 200mts per month |

|

Detail Information |

|||

| Main Material: | 60-66% ZrO2 | Usage: | Open Sandblasting Machine |

|---|---|---|---|

| Commodity: | Ceramic Beads | Product Name: | Ceramic Blasting Media |

| Bulk Density: | 2.3 G/cm3 | True Gravity: | 3.85 G/cm3 |

| Vicker Hardness: | 700HV | Shape: | Solid Round Ball |

| Highlight: | Metal Surface Finishing Ceramic Beads,B120 Ceramic Bead Blasting,ZrO2 Ceramic Beads |

||

Product Description

Ceramic beads B120 size 0.063-0.125mm for Metal surface finishing

- DESCRIPTION

Ceramic beads is a zirconia based material and with ZrO2 about 60-62%, SiO2 25-30%.

Ceramic blasting media is widely used for sandblasting surface finish.

Applicable for Metal surface finishing and cleaning without dimensional change.

Materials Applicable:

- Aluminium

- Aluminium alloy

- Steel

- Stainless steel

- Titanium alloy

- Magnesium alloy

- Brass

- Copper, etc.

- SPECIFICATION

|

Chemical & Physical Index

|

||||||

| Chemical Index | Production Process | True Density | Bulk Density | Hardness | ||

| Vickers | Mohs | Rockwell | ||||

|

ZrO2 : 60-66% SiO2: 25-30% Al2O3: 7-13% |

Smelting | 3.85 | 2.3 | 700HV | 7 | 60HRC |

|

Sizes

|

||||||

| B20: 0.600-0.850mm | B80: 0.125-0.212mm | B170: 0.045-0.090mm | ||||

| B30: 0.425-0.600mm | B100: 0.106-0.180mm | B205:0.000-0.063mm | ||||

| B40: 0.250-0.425mm | B120: 0.063-0.125mm | B400: 0.030-0.063mm | ||||

| B60: 0.150-0.300mm | B150: 0.053-0.106mm | B505: 0.010-0.063mm | ||||

|

Features of Ceramic beads

|

||||||

|

|

||||||

|

Parameters- (Comparing with glass beads and steel shot)

|

||||||

| Parameters | Ceramic Beads | Glass Beads | Steel Shot | |||

| Chemical index | ZrO2+SiO2+Al2O3 | SiO2+NaO2 | C+Si+Mn+S+P | |||

| Vickers Hardness | ≈700HV | ≈560HV | ≈700HV | |||

| Rockwell Hardness | ≈60HRC | ≈46HRC | ≈60HRC | |||

| True Density | 3.85g/cm3 | 2.6 g/cm3 | 7.8 g/cm3 | |||

| Size range | 0.04-0.85mm | 0.045-0.85mm | 0.05-0.60mm | |||

| Shape | spherical | spherical | fillet | |||

| Dust Pollution | Very little | big | medium | |||

| Metal Pollution | no | no | spherical | |||

| Recycling times | Multi-time | 1-2 times | Multi-time | |||

| Work life | Long | Low 1/25 of ceramic beads | Long | |||

| Power consumption | Low | Low | High | |||

| Equipment wear loss | Low | Low | High | |||

| Sandblasting effect | High finish, no discoloration | High finish, whitish | Low finish, darken | |||

|

Applicable Equipment

|

||||||

|

|

||||||

|

Package

|

||||||

|

25kgs /Barrel+Pallet or 12.5kgs/Barrel, 2 barrels / Paper carton+Pallet

|

||||||

- APPLICATION

Ceramic beads is widely used for sandblasting of bikes frame.

![]()

CONTACT US

YOU CAN LEAVE US MESSAGES HERE OR SEND US INQUIRY BY EMAIL.