B60 700HV Ceramic Blasting Media For Medical Artificial Joints

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kg barrel+pallet or 2*12.5kg barrel+carton+pallet |

| Delivery Time: | 3-5 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 250mts monthly |

|

Detail Information |

|||

| Commodity: | Ceramic Blasting Media | Product Name: | Ceramic Beads,Ceramic Microspheres |

|---|---|---|---|

| Color: | White | True Gravity: | 3.85g/cm3 |

| Bulk Density: | 2.3g/cm3 | Hardness: | 50-65 HRC |

| Sphericity: | ≥85% | Usage: | Surface Cleaning,Surface Finish,Surface Preparation |

| Highlight: | 700HV Ceramic Blasting Media,B60 Ceramic Blasting Media,65 HRC Ceramic Blasting Media |

||

Product Description

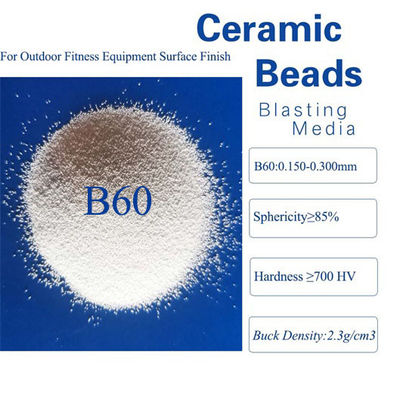

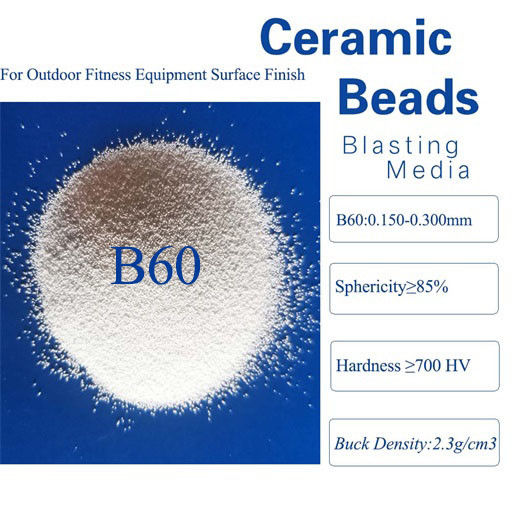

700HV Ceramic Blasting Media Microspheres B40 B60 B80 B100 B120 for Medical Artifical Joints

1. Product Description of Ceramic Blasting Media

Ceramic beads is one clean blasting media,it contains 60-66% ZrO2,so it is also called as zirconia sand.

It is able to replace glass beads where one clean working condition is required,widely used for surface

finish in metal,plastic,rubber parts.

2. Main Technical Data of Ceramic Blasting Media

| Item | Ceramic Blasting Beads | Particle Size | |

| Chemical Index | ZrO2 60-66% SiO2 25-30% Al2O3 7-13% |

B20:0.600-0.850mm | B120:0.063-0.125mm |

| B30:0.425-0.600mm | B150:0.053-0.106mm | ||

| B40:0.250-0.425mm | B170:0.045-0.090mm | ||

| Vicker Hardness | ≥700 HV | B60:0.150-0.300mm | B205:0.000-0.063mm |

| True Specific Gravity | ≥3.85 g/cm3 | B80:0.125-0.212mm | B400:0.030-0.063mm |

| Bulk Density | ≥2.3g/cm3 | B100:0.106-0.180mm | B505:0.010-0.030mm |

3. Main Features:

High hardness& mechanical strength

Low break-down rate,no hidden danger of silicosis

No ferrous contamination

More consistent blasting effect

Low solid-waste treatment cost

4. Main Applications:

Surface finish for aluminum alloy,magnesium alloy, titanium alloy

Surface finish for stainless steel parts

Surface finish for plastic and rubber parts

Surface cleaning for molds,tires,die casting etc.

Surface preparation before electroplating,anodizing etc

Surface strengthening for hard alloys & metallic alloys etc.

![]()

5. Why Choose us?

Professional manufacturer of ceramic beads,annual output over 3000mts;

Quick and professional quotation& service,free sample and fast delivery;

Stable quality,all the cargo even for one sample in small quantity will be tested again before shipment;

Strict quality control system,products can be traced in every step from the very begining of raw materials

to the final products;

Flexible delivery and payment method to meet the customer’s different requirement;

More competitive price/performance ratio;

Stable supplier of Samsung,Foxconn etc.

6. Questions(Q) & A (Answer)

Q: Are you manufacturer and how about your annual output?

A: Yes,we are direct manufacturer,annual output is 3000mts.

Q: What is the MOQ?

A: MOQ is 25 kgs,it will be shipped by TNT or Fedex or DHL Express.

Q: Payment Term

A: T/T,L/C,paypal or money gram are also acceptable.

Q: How long the cargo will be shipped after payment made?

A: For small order shipped by air way,we will arrange the shipment within 3 days;

For order quantity more than 100kgs,shipped by sea way,cargo will be loaded into the vessel within 10 days

after payment made;

Q: Do you provide free sample?

A: Yes,free sample no more than 500g is available.

Q: Which country you export to?

A: Our products has been exported to South Korea,Vietnam,Thailand,Italy,Australia,United Kingdom,U.S.A,

Middle East etc.