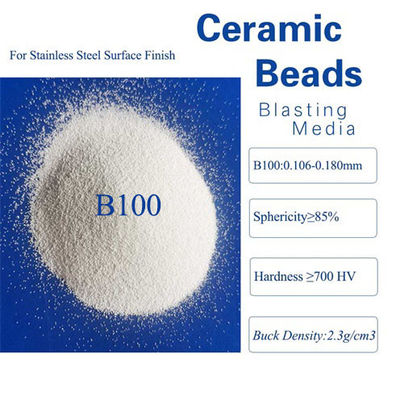

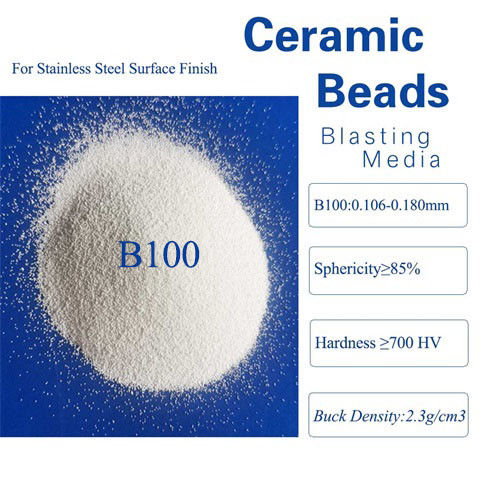

Melting 700HV B100 56 HRC Ceramic Blasting Media

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kg barrel+pallet or 2*12.5kg barrel+carton+pallet |

| Delivery Time: | 3-5 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 250mts monthly |

|

Detail Information |

|||

| Commodity: | Ceramic Blasting Media | Product Name: | Ceramic Beads,Ceramic Microspheres |

|---|---|---|---|

| Color: | White | True Gravity: | 3.85g/cm3 |

| Bulk Density: | 2.3g/cm3 | Hardness: | 700HV |

| Sphericity: | ≥85% | Usage: | Blasting Media |

| Highlight: | 56 HRC Ceramic Blasting Media,B100 Ceramic Blasting Media,700HV Ceramic Blasting Media |

||

Product Description

50-65HRC Ceramic Blasting Media B100 B120 B170 B205 B400 B505 for Metal & Plastic Surface Finish

1. Product Description of Ceramic Beads

Ceramic Beads selects the high quality zircon sand as main raw materials,then fused in electric furnace

under high temperature over 2000℃,then made into beads in different size,it is one popular blasting media,

which is mainly used in surface finish for metal,plastic and rubber parts.

2. Main Technical Data of Ceramic Beads

| Commodity | Ceramic Blasting Media | |

| Chemical Index | ZrO2 60-66% SiO2 25-30% Al2O3 7-13% |

|

| Physical Index | Vickers Hardness ≥700 HV Bulk Density≥2.3g/cm3 True Gravity: 3.85g/cm3 Process: Melting |

|

| Particle Size | B20: 0.600-0.850mm | B120: 0.063-0.125mm |

| B30: 0.425-0.600mm | B150: 0.053-0.106mm | |

| B40: 0.250-0.425mm | B170: 0.045-0.090mm | |

| B60: 0.150-0.300mm | B205: 0.000-0.063mm | |

| B80: 0.125-0.212mm | B400: 0.030-0.063mm | |

| B100: 0.106-0.180mm | B505: 0.000-0.030mm | |

| Remark: Special specification can be customized | ||

3. Main Applications

Surface finish for Metal Parts made by aluminum,aluminum alloy,magnesium alloy,titanium alloy,stainless

stell etc.

Surface finish for plastic parts: the in-built parts ,frame of 3C products etc.

![]()

4. Why ceramic bead is widely used for surface finish of aluminum parts?

The blasting principle of ceramic bead is to make use of the impact of high-speed sand flow to clean and

roughen the metal surface.

When the surface of aluminum parts is treated in that way,it will obtain a certain degree of cleanliness and

different roughness in the surface, improve its mechanical properties ,finally improve its anti-fatigue and

increase the adhension,it will extend the durability of the coating film, and is also conducive to the leveling

and decoration of the coating.

In addition,there is little dust generation in the whole blasting process,which will provide one clean and

bright blasting condition,it is one clean blasting media,the worker will escape form the hidden danger of

silicosis.

At last,ceramic beads has low breakdown rate,its service life can be prolonged 20-30 times compared

the one of glass beads,it has more competitive price/performance ratio seen from the long-term blasting

process.

So ceramic beads is widely used for surface finish of aluminum parts.

5. Questions & Answers

Q: Are you manufacturer of ceramic beads? Where your plant locates in?

A: Yes,we are direct manufacturer,our plant locates in Shanxi,China.

Q: Is free sample available?

A: Yes,free sample no more than 500g is available.

Q: What is your MOQ?

A: Generally speaking, MOQ is 12.5kg,but for special requirement,smaller quantity is also acceptable.

Q:How about the payment terms?

A: L/C,T/T,paypal,money gram is also accepatable.

Q:How long the cargo will be loaded into the vessel?

A:For order quantity no more than 2mts,Cargo will be shipped to the vessel within 10 days after payment

received.

Q:How about the Quality Guarantee?

A: All the material can be tracable from the raw material to the final products, products will be sampled

before delivery even for free sample in small quantity.