Ceramic media B40 high cost effective recyclable for 70-90 cycles

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 2*12.5kg barrel+ carton box + pallet or 25kg barrel+pallet |

| Delivery Time: | 3-5 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 200mts per month |

|

Detail Information |

|||

| Commodity: | Ceramic Blasting Beads | Product Name: | Ceramic Blasting Media |

|---|---|---|---|

| Usage: | Surface Finish For 3C Products | Bulk Density: | 2.3 G/cm3 |

| True Gravity: | 3.85 G/cm3 | Main Material: | 60-66% ZrO2 |

| Vicker Hardness: | 700 HV | Shape: | Solid Round Ball |

| Highlight: | B40 Blasting Abrasive Media,Recyclable Blasting Abrasive Media,3C Products Blasting Abrasive Media |

||

Product Description

Ceramic media B40 high cost effective recyclable for 70-90 cycles

DESCRIPTION of sandblasting ceramic media

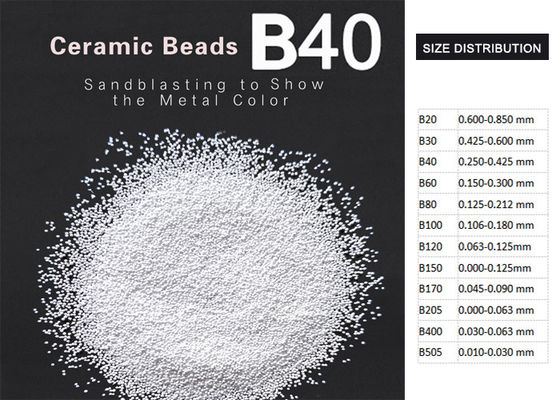

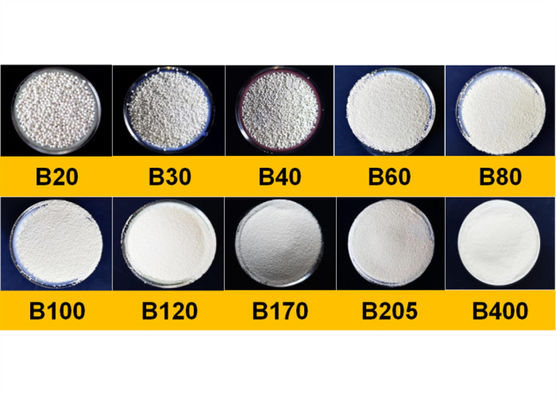

Ceramic beads blasting media is available in different sizes from B20 to B505, spherical shapes and high hardnesses with Mohs 7 and Rockwell 55-65, and is recyclable for multiple use, about 70-90 cycles.

The recycling ceramic media reduce the cost and save resources and ensures a dust-free and healthy working environment.

| Technical Data | |||

| Components | Content | CAS No. | EC No. |

| ZrO2 (Zirconium dioxide) | 60-68% | 1314-23-4 | 215-227-2 |

| SiO2 (Silicon dioxide) | 25-30 | 60676-86-0 | 262-373-8 |

| Al2O3 (Aluminum oxide ) | 7-13% | 1344-28-1 | 215-691-6 |

| Manufacturing Method | Melting in above 2000℃ furnace | ||

| True Density | 3.85 g/cm3 | ||

| Bulk Density | 2.3g/cm3 | ||

| Vicker Hardness | 700HV | ||

| Sizes for Sand Blasting | |||

| Bead Size | Size range | Bead Size | Size range |

| B20 | 0.60-0.85 mm | B120 | 0.063-0.125 mm |

| B30 | 0.425-0.60 mm | B125 | 0.000-0.125 mm |

| B40 | 0.24-0.425 mm | B170 | 0.045-0.090 mm |

| B60 | 0.125-0.25 mm | B205 | 0.000-0.063 mm |

| B80 | 0.18-0.25 mm | B400 | 0.030-0.063 mm |

| B100 | 0.125-0.18 mm | B505 | 0.000-0.030 mm |

| Sizes for Shot Peening | |||

| Z850 | 0.85-1.18 mm | Z210 | 0.21-0.30 mm |

| Z600 | 0.6-0.85 mm | Z150 | 0.15-0.21 mm |

| Z425 | 0.425-0.60 mm | Z100 | 0.10-0.15 mm |

| Z300 | 0.30-0.425 mm | ||

![]()

FEATURES of sandblasting ceramic media

- High impact resistance and round beads, not easy to be broken. The broken rate of ceramic beads is around 1%.

- Low dust generation, friendly to the environment and worker’s health.

- Matte Metallic luster, no polishing reflective.

- No metal pollution.

APPLICATION of sandblasting ceramic media

Applicable Materials

- Aluminum

- Aluminum alloy

- Magnesium alloy

- Stainless steel

- Copper

Applicable process in sandblasting

- Coating/Painting removal

- Matting

- Satin Finish

- Rust removal

- Deburring

APPLICABLE EQUIPMENT

- Applicable equipment:

- Manual sandblasting machine

- Automatic sandblasting machine

- Mobile sandblasting machine

- Sandblasting room, etc.

- Dry sandblasting machine

- Wet sandblasting machine

- Vapour sandblasting machine

CONTACT US

Contact us to choose the favourable ceramic beads to upgrade your sandblasting process.