B30 size 425-600μm Sandblasting Ceramic Blasting Media for metal surface finish

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 12.5kgs/barrel, 25kgs (2 barrels)/paper carton, or 25kgs barrels +pallet |

| Delivery Time: | 5-10 days |

| Supply Ability: | 1500mt per year |

|

Detail Information |

|||

| Commodity Name: | Ceramic Beads Blasting Media | Chemical Index: | ZrO2 60-66%, SiO2 25-30%, Al2O3 7-13% |

|---|---|---|---|

| Manufacturing Process: | Melting Method | Bulk Density: | 2.3g.cm3 |

| True Density: | 3.85g/cm3 | Hardness: | 700HV |

| Package: | 25kgs Paper Cartons Or 25kgs Barrels +pallet | ||

| Highlight: | Sandblasting Ceramic Blasting Media,700HV Ceramic Blasting Media,B30 Ceramic Bead Blasting |

||

Product Description

B30 size 425-600μm Sandblasting Ceramic Blasting Media for metal surface finish

DESCRIPTION

The ceramic beads is made from Australia imported zirconium sand, through electro fusion., then made to micro beads by blowing technology,

The ceramic beads have a fine internal structure of zirconium crystals in a glassy silicon dioxide cover., with features are high density and high impact resistance.

It is sand- blasting media for metal surface treatment process like coating removal, matting, satinising, polishing, rust removal, deburring, etc.

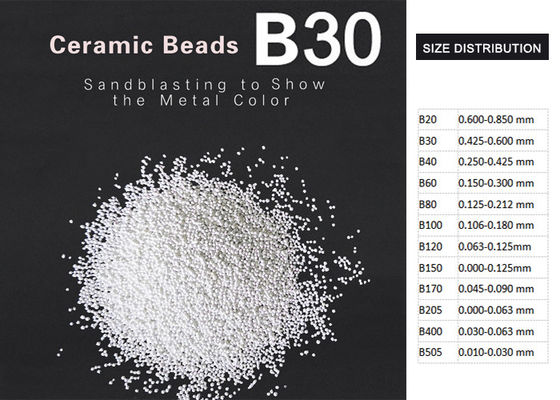

SPECIFICATION

Manufacturing process: Melting method

| ZrO2 | SiO2 | Al2O3 | Other |

| 60-66%, | 25-30% max. | 7-13% max. | 5-8% |

| Color | Bulk Density | True Specific Density | Vickers Hardness |

| White | 2.3g/cm3 | 3.85g/cm3 | 700 HV |

| Grit size | B20 | B30 | B40 | B60 | B80 | B100 | B120 |

| Microns μm | 600-850 | 425-600 | 250-425 | 125-250 | 180-250 | 125-180 | 63-125 |

| Grit size | B125 | B170 | B205 | B400 | B505 |

Special sizes can be customized |

|

| Microns μm | 0-125 | 45-90 | 0-63 | 30-63 | 0-63 | ||

| Grit size | Z850 | Z600 | Z425 | Z300 | Z210 | Z150 | Z100 |

| Microns | 850-1180 | 600-850 | 425-600 | 300-425 | 210-300 | 150-210 | 100-150 |

FEATURES

- High impact resistance and round beads, not easy to be broken. The broken rate of ceramic beads is around 1%.

- Low dust generation, friendly to the environment and worker’s health.

- Matte Metallic luster, no polishing reflective.

- No metal pollution.

APPLICATION

1) 3C products - Sandblasting Finishing

2) Aerospace industry-Blasting finishing

3) Automotive industry-sandblasting reinforcement

4) Kitchen Industry-Sandblasting finishing

5) Machinery, Medical Instrument - Sandblast finishing

6) Casting, forging , welded, heat-treated parts - Sandblast Cleaning

7) Pipeline - Sandblast Cleaning

8) Molds - Sandblast cleaning

9) Electroplating, painting, anode-Surface Pre-treatment.

10) Hardware parts - Sandblast to improve lubrication conditions.

CONTACT US

Other abrasive blasting media also available:

- Brown aluminium oxide

- Black aluminium oxide

- White aluminium oxide

![]()

Contact us to choose the favourable blasting media to upgrade your sandblasting process.