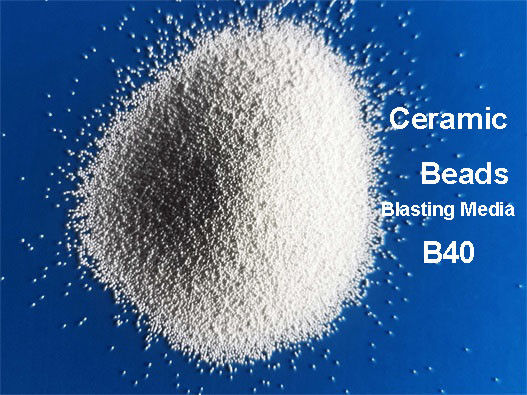

Mold Cleaning Micro Spheres B40 425μM 700HV Ceramic Bead Blasting Media

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25 kg(12L) barrel + Pallet |

| Delivery Time: | 3-5 days after order confirmed |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200mts per month |

|

Detail Information |

|||

| Commodity: | Ceramic Blasting Media | Product Name: | Ceramic Micro-Spheres |

|---|---|---|---|

| Usage: | Blasting Media | Chemical Index: | ZrO2 60-66%, SiO2 25-30%, Al2O3 7-13% |

| Vicker Hardness: | 700HV Min | Buck Density: | 2.2±0.1 G/cm3 |

| Shape: | Spherical | Sphericity: | 85% |

| Highlight: | B40 abrasive media blasting,700HV ceramic bead blasting |

||

Product Description

700HV Ceramic Beads Blasting Media Micro-Spheres B40 250-425μm For Mold Cleaning

1. Product Description of Ceramic Beads Blasting Media

Ceramic Beads is also called as ceramic micro-spheres,it selected the high quality zircon sand as main

material,then fused in arc furnace under high temperature over 2000 degrees,then made into different

beads by special technology.

The Zirnano ceramic beads has wide size from B20 to B505.

Zirnano Ceramic Beads B120,B170,B205,B400,B505 has the same particle size distribution as the one of

Microblast, and Zirnano Ceramic blasting media B20,B30,B40,B60,B80,B100 also has the similar particle

size distribution as the one of Zirblast.

Here we simiply make a comparation between Zirnano Ceramic Beads and Zirblast,microblast as below:

| Item | Zirnano Ceramic Beads | Zirblast | Microblast |

| Chemical Index | ZrO2 60-66% SiO2 25-30% Al2O3 7-13% |

ZrO2 60-70% SiO2 28-33% Al2O3 <10% |

ZrO2 60-70% SiO2 28-33% Al2O3 <10% |

| Vickers Hardness | ≥700 HV | ≥700HV | ≥700HV |

| True Specific Gravity | ≥3.85 g/cm3 | ≥3.85 g/cm3 | ≥3.80 g/cm3 |

| Bulk Density | ≥2.3g/cm3 | ≥2.3g/cm3 | ≥2.1g/cm3 |

| Particle Size | B20 600-850μm | B20 600-850μm | / |

| B30 425-600μm | B30 425-600μm | ||

| B40 250-425μm | B40 250-425μm | ||

| B60 150-300μm | B60 125-250μm | ||

| B80 125-212μm | B80 180-250μm | ||

| B100 106-180μm | B100 125-180μm | ||

| B120 63-125μm | / | B120 63-125μm | |

| B150 53-106μm | B125 0-125μm | ||

| B170 45-90μm | B170 45-90μm | ||

| B205:0-63μm | B205:0-63μm | ||

| B400:30-63μm | B400:30-63μm | ||

| B505:10-30μm | B505:10-30μm |

Seen from the above chart,zirnano ceramic beads has the similar chemical composition and almost the

same specification as the one of Zirblast & Mircroblast.

If you are looking for one new blasting media same as Microblast or Zirblast , Zirnano ceramic beads is

your best choice.

2. Main Applications of Ceramic Beads

Pretreatment berore plating,painting etc

Sandblasting for the metallic surfaces such as steel surfaces,stainless steel surfaces,aluminum surfaces etc

Surface finish for light metal such as magnesium alloy,titanium alloy etc

Surface cleaning for glass-bottle molds,tire-molds,rubber-molds,plastic molds etc.

Deburring for electronic products such as circuit board etc

3. Main Package of Ceramic Beads:

25KG(12L) Barrel + Pallet

2*12.5KG Barrel+ Carton + Pallet

25KG (12L) Barrel+ Wooden box or 2*12.5KG Barrel+ Carton+Pallet.

![]()

4. Why Choose Us?

Professional manufacturer of ceramic beads,anual output over 3000mts

Products has almost the same quality as the one Zirblast & Microblast,but in more competitive price/performance ratio;

Stricter quality control system,products can be traced in each step;

Certified by ISO9001,IS14001 etc;

Screened more than six times and blow-cleaning under high temperature,which provides higher clearliness and ensures it to be work normally in humid weather;

Stable supplier of Foxconn,Samsung Electronics,Ujiden,Murata etc.