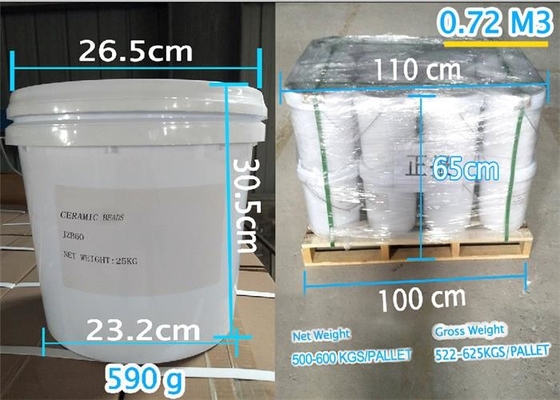

25kgs 55lbs Bucket Packaged Ceramic Blasting Media Fracture Resistance

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B400 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 12.5kgs/barrel, 25kgs (2 barrels)/paper carton, or 25kgs barrels +pallet |

| Delivery Time: | 5-10 days |

| Supply Ability: | 1500mt per year |

|

Detail Information |

|||

| Chemical Index: | ZrO2 60-66%, SiO2 25-30%, Al2O3 7-13% | Bulk Density: | 2.3g.cm3 |

|---|---|---|---|

| True Density: | 3.85g/cm3 | Commodity Name: | Ceramic Beads Blasting Media |

| Hardness: | 700HV | Package: | 25kgs Paper Cartons Or 25kgs Barrels +pallet |

| Highlight: | abrasive blasting media,ceramic bead blasting media |

||

Product Description

25kgs (55lbs) bucket packaged ceramic media for deburring of low surface abrasion

Description

Ceramic beads are manufactured by electric fusion at high temperatures in ore furnace, with high wear and fracture-resistance. Production process including smelting-flow into micro beads-screen- air cleaning and fine screen to different sizes from B20 to B505, and Z100-Z850.

Our Ceramic beads are available in both sandblasting surface finishing grade and shot peening grade.

![]()

Sizes

Sandblasting surface finishing grade

| B20 | 0.600-0.850 mm |

| B30 | 0.425-0.600 mm |

| B40 | 0.250-0.425 mm |

| B60 | 0.150-0.300 mm |

| B80 | 0.125-0.212 mm |

| B100 | 0.106-0.180 mm |

| B120 | 0.063-0.125mm |

| B150 | 0.000-0.125mm |

| B170 | 0.045-0.090 mm |

| B205 | 0.000-0.063 mm |

| B400 | 0.030-0.063 mm |

| B505 | 0.010-0.030 mm |

Shot peening grade

| Z850 | 0.850-1.180 mm |

| Z600 | 0.600-0.850 mm |

| Z425 | 0.425-0.600 mm |

| Z300 | 0.300-0.425 mm |

| Z210 | 0.210-0.300 mm |

| Z150 | 0.150-0.212 mm |

| Z100 | 0.100-0.150 mm |

Application

1) 3C products - Sandblasting Finishing

2) Aerospace industry-Blasting finishing

3) Automotive industry-sandblasting reinforcement

4) Kitchen Industry-Sandblasting finishing

5) Machinery, Medical Instrument - Sandblast finishing

6) Casting, forging , welded, heat-treated parts - Sandblast Cleaning

7) Pipeline - Sandblast Cleaning

8) Molds - Sandblast cleaning

9) Electroplating, painting, anode-Surface Pre-treatment.

10) Hardware parts - Sandblast to improve lubrication conditions.

![]()

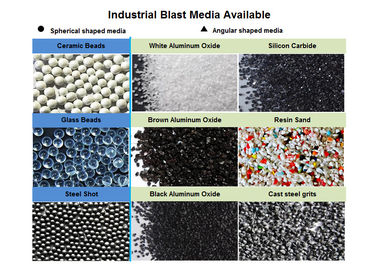

Other sandblasting abrasive available

01. Ceramic Beads..............................................01

02. Glass Beads.................................................. 02

03. Steel Shot......................................................03

04. Brown fused alumina.....................................04

05. White fused alumina......................................05

06. Black fused alumina......................................06

07. Black silicon carbide......................................07

08. Green silicon carbide....................................08

09. Steel Grits.....................................................09

10. Plastic Sand...................................................10

11. PA Nylon sand ..............................................11

12. PC Frozen sand.............................................12

13. Steel wire cut..................................................13

14. Aluminium wire cut.........................................14

15. Zinc wire cut...................................................15

16. Spherical zinc powder....................................16

More details please send us email to get our catalogue 2022.