Blasting media Difference of Glass beads, Ceramic beads and steel shot in sandblasting

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 12.5kgs/barrel, 25kgs (2 barrels)/paper carton, or 25kgs barrels +pallet |

| Delivery Time: | 5-10 days |

| Supply Ability: | 1500mt per year |

|

Detail Information |

|||

| Commodity Name: | Ceramic Beads Blasting Media | Chemical Index: | ZrO2 60-66%, SiO2 25-30%, Al2O3 7-13% |

|---|---|---|---|

| Manufacturing Process: | Melting Method | Bulk Density: | 2.3g.cm3 |

| True Density: | 3.85g/cm3 | Hardness: | 700HV |

| Package: | 25kgs Paper Cartons Or 25kgs Barrels +pallet | ||

| Highlight: | bead blasting material,ceramic bead blasting media |

||

Product Description

Blasting media Difference of Glass beads, Ceramic beads and steel shot in sandblasting

DESCRIPTION

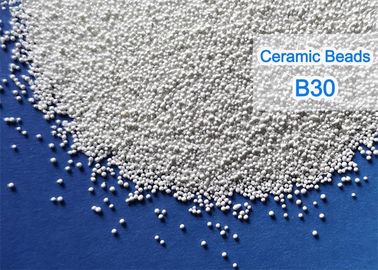

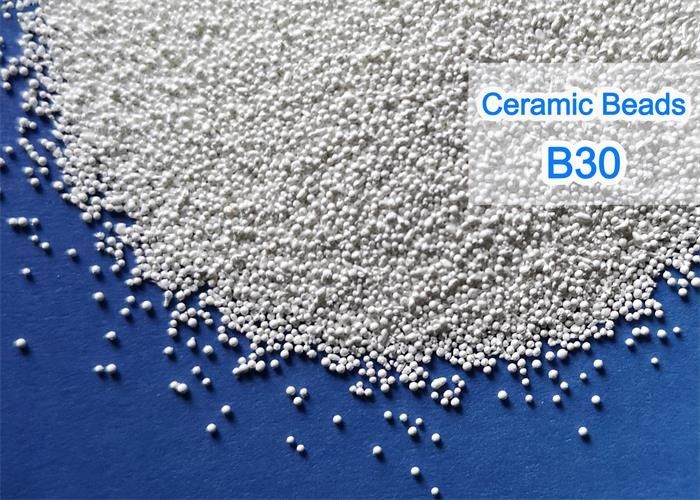

Ceramic blasting media is also called Ceramic beads, ZrO2 62-68%, Bulk Density 2.3g/cm3, HS code 691410.

Ceramic beads is of high impact properties coupled with good hardness. It is spherical and of smooth surface,

much lower roughness than glass beads and steel shot, leading beautiful satin shine finish on the blasting work

piece and easier to clean.

SPECIFICATION

Manufacturing process: Melting method

| ZrO2 | SiO2 | Al2O3 | Other |

| 60-66%, | 25-30% max. | 7-13% max. | 5-8% |

| Color | Bulk Density | True Specific Density | Vickers Hardness |

| White | 2.3g/cm3 | 3.85g/cm3 | 700 HV |

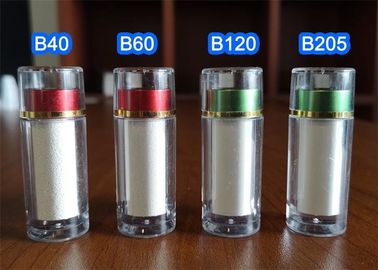

| Grit size | B20 | B30 | B40 | B60 | B80 | B100 | B120 |

| Microns μm | 600-850 | 425-600 | 250-425 | 125-250 | 180-250 | 125-180 | 63-125 |

| Grit size | B125 | B170 | B205 | B400 | B505 |

Special sizes can be customized |

|

| Microns μm | 0-125 | 45-90 | 0-63 | 30-63 | 0-63 | ||

| Grit size | Z850 | Z600 | Z425 | Z300 | Z210 | Z150 | Z100 |

| Microns | 850-1180 | 600-850 | 425-600 | 300-425 | 210-300 | 150-210 | 100-150 |

FEATURES

1. The density of the ceramicbeads is between glass beads and steel shot, and with high hardness, can be used to fill the upper and lower limit of the strength of glass beads and steel shot.

2. The ceramic beads is light, but its hardness is high, which is very suitable for the strengthening and forming of metal blasting sand such as titanium alloy, aluminum alloy and high temperature alloy.

3. Ceramic beads is not deformed in the process of circulation and wear low, which can ensure the consistency of the surface sandblasting effect during mass production.

4. Ceramic beads is spherical and has smooth surface and low loss of equipment.

5. Ceramic beads has a wider range of particle size and can be used in matching with various types of sandblasting machines to meet more application requirements.

![]()

| Parameter | Ceramic beads | Glass beads | Steel shot |

| Main ingredient | ZrO2+SiO2 | SiO2+NaO2 | C+Si+Mn+S+P |

| Vickers hardness | ≈700HV | ≈560HV | ≈700HV |

| Rockwell hardness | ≈60HRC | ≈46HRC | ≈60HRC |

| True density | 3.85g/cm3 | 2.6 g/cm3 | 7.8 g/cm3 |

| Particle size interval | 0.04-0.85mm | 0.045-0.85mm | 0.05-0.60mm |

| Particle shape | spherical | spherical | Fillet |

| Dust pollution | Very small | Big | in |

| Metal pollution | no | no | in |

| Cycles | repeatedly | 1-2 times | repeatedly |

| Service life | high | About ceramic sand 1/25 | high |

| power consumption | low | low | high |

| Equipment wear | low | low | high |

| Sandblasting effect | High finish and no discoloration of the workpiece | High finish and white workpiece | Low finish and blackened workpiece |

APPLICATIONS

Sandblasting finishing

- 1) 3C products - Sandblasting Finishing

Alloy shell, middle frame and built-in parts of computers, mobile phones, cameras, etc. - sandblasting finishing

Clean burrs to form film-light decorative or fine reflective surface, on alloy workpiece such as mobile phone to achieve different reflection or matte.

- 2) Kitchen Industry-Sandblasting finishing

Stainless steel cutlery and kitchen utensils sandblasting finishing

- 3) Golf club - Sandblasting finishing

Golf club & ball head alloy surface treatment Sandblasting finishing

Other applications in

Sandblasting cleaning

Casting and forging parts, welded parts, heat-treated parts - Sandblast Cleaning

Pipeline - Sandblast Cleaning

Molds - Sandblast cleaning

Pretreatment

Electroplating, painting, anode-Surface Pretreatment

Hardware parts - Sandblasting to improve lubrication conditions

Shot peening

Aerospace industry-Shot Peening

Automotive industry-Sandblasting reinforcement/ Shot Peening

Machinery, Medical Instrument - Sandblast finishing/shot peening

CONTACT US

No matter you’re the end users, blasting service suppliers, sandblasting equipment dealers or ceramic blasting media and other blasting abrasive distributors, welcome to contact us. More details of ceramic blasting beads, updated prices and samples will be available.

Caroline Cui