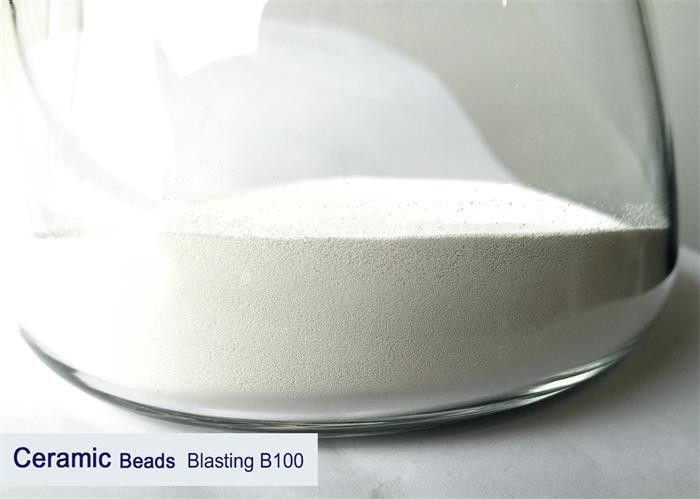

B100 Ceramic Blasting Media For Machinery / Medical Instrument Sandblast Finishing

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B100 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 12.5kgs/barrel, 25kgs (2 barrels)/paper carton, or 25kgs barrels +pallet |

| Delivery Time: | 5-10 days |

| Supply Ability: | 1500mt per year |

|

Detail Information |

|||

| Commodity Name: | Ceramic Beads Blasting Media | Chemical Index: | ZrO2 60-66%, SiO2 25-30%, Al2O3 7-13% |

|---|---|---|---|

| Manufacturing Process: | Melting Method | Bulk Density: | 2.3g.cm3 |

| True Density: | 3.85g/cm3 | Hardness: | 700HV |

| Package: | 25kgs Paper Cartons Or 25kgs Barrels +pallet | ||

| Highlight: | abrasive blasting media,ceramic bead blasting media |

||

Product Description

B100 Ceramic Blasting Media For Machinery / Medical Instrument Sandblast Finishing

DESCRIPTION OF CERAMIC BLASTING MEDIA

Ceramic Bead is spherical sandblasting media made by the electric fusion of zirconia sand at 2000 ℃ temperature .

Ceramic bead blasting is used for surface treatment cleaning and finishing on metallic parts surfaces, like descaling, derusting, deburing, and deflashing, to remove layers of foreign material from metallic substrates and excess surface material from machined or molded parts.

SPECIFICATION OF CERAMIC BLASTING MEDIA

Manufacturing process: Melting method

| ZrO2 | SiO2 | Al2O3 | Other |

| 60-66%, | 25-30% max. | 7-13% max. | 5-8% |

| Color | Bulk Density | True Specific Density | Vickers Hardness |

| White | 2.3g/cm3 | 3.85g/cm3 | 700 HV |

Sizes

| B20 | B30 | B40 | B60 |

| 600-850µm | 425-6000µm | 0250-425µm | 125-250µm |

| B80 | B120 | B170 | B205 |

| 180-250µm | 63-125µm | 45-90µm | 0-63µm |

Special sizes available against clients’ requirement.

PRODUCTION PROCESS

![]()

FEATURES

(1) Surface treatment consistency

Consistency of metallic light, the blasting strength is as good as steel balls processing effect, much higher than the glass beads strength. And can achieve adequate metal depth.

(2) Environmental Friendly

Low crushing rate, no dust, uniform particle size, high wear resistance, re-elasticity, no hidden danger of silicosis, it is harmless to the human body.

(3) Low equipment loss

Ceramic sand has smooth surface, high sphericity, good elasticity and low wear, can protect the equipment, whether it is dry spray or wet spray.

APPLICATION

![]()

Machinery, Medical Instrument - Sandblast finishing

Ceramic beads can be used as blasting medium for medical equipment, can achieve effect of micro-burr removal, make the corners of the two surfaces appear small rounded corners, the surface is smooth and non-reflective.

Other application like Sandblasting finishing, Surface cleaning, Surface Pretreatment and Renovation of old work parts etc..

APPLICABLE EQUIPMENT

Suitable sand blasting machine:

Manual sand blasting machine, Automatic sand blasting machine,

Open type series of sand blasting machine, and Blasting room series.