AMS Ceramic Shot Peening Z210 Z300 Z850 Shot Blasting Material For Aircraft Engines

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | Z100-Z850 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | By Negotiable |

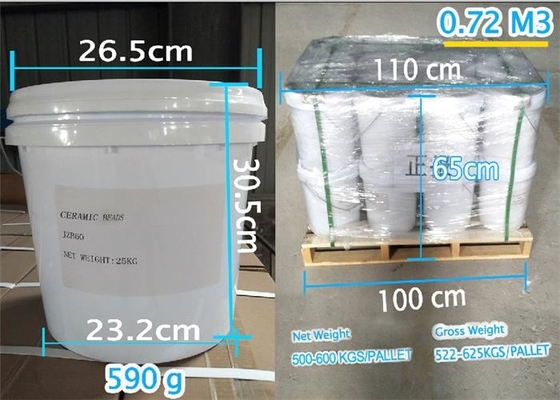

| Packaging Details: | 25kgs barrel+ pallet or woodencase |

| Delivery Time: | 3-5 days after order confirmed |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 2000mts annually |

|

Detail Information |

|||

| Product Name: | Ceramic Shot Peening | Size: | Z100,Z150,Z210,Z300,Z425,Z600,Z850 |

|---|---|---|---|

| Application: | Shot Peening | True Gravity: | 3.85 G/cm3 |

| Bulk Density: | 2.3 G/cm3 | Hardness: | 700HV Min |

| Chemical Index: | 60-66% ZrO2, 25-30% SiO2, 7-13%Al2O3 | Quality Standard: | AMS |

| Highlight: | AMS Ceramic Shot Peening,Ceramic Shot Peening Z210,Shot Blasting Material For Aircraft Engines |

||

Product Description

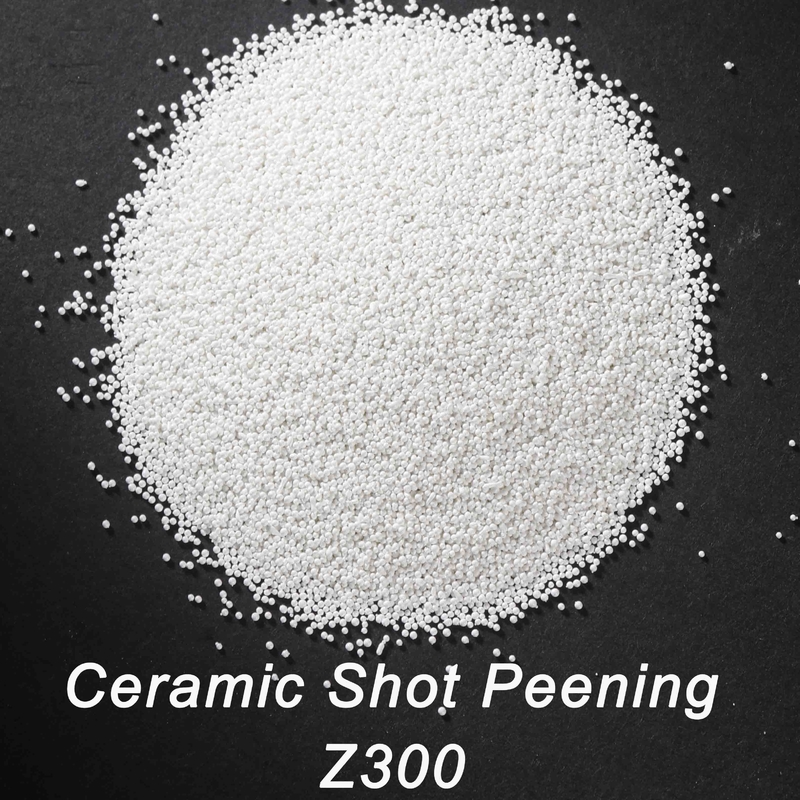

AMS Ceramic Shot Peening Z210 Z300 Z850 for Aircraft Engines

1. Product Description of Ceramic Shot Peening

Compared with ceramic blasting media,ceramic shot peening has the same chemical composition,while

in more narrow particle size distribution,higher sphericity, and special requirements on satellites. It ranges

from Z100,Z150,Z210,Z300,Z425,Z600,Z850, and the most popular size is Z210,Z300.

2. Main Technical Data of Ceramic Shot Peening

| Commodity | Process | Chemical Index | Physical Index |

| Ceramic Beads | Melting | ZrO2 60-66% | Bulk density:2.3g/cm3 |

| SiO2 25-30% | True Gravity ≥3.85 g/cm3 | ||

| Al2O3 7-13% | Vicker Hardness≥700 HV | ||

| Particle Size | Z100: 100-150μm | Z425:425-600μm | |

| Z150: 150-210μm | Z600: 600-850μm | ||

| Z210: 210-300μm | Z850: 850-1180μm | ||

| Z300: 300-425μm | / | ||

| Remark: Special specification can be customized | |||

3. Main Applications of Ceramic Shot Peening

Surface strengthening for Aircraft Turbine Blades...

Shot Peening for Automotive Wheel Hub...

4 The Comparation between Ceramic Beads and Ceramic Shot Peening

Same Chemical Composition

Both ceramic beads and ceramic shot peening has the same chemical composition.

Different particle size

The particle size of ceramic beads ranges from B20(0.600-0.850mm) to B505(0.010-0.030mm),while

the one of ceramic shot peening ranges from Z850(0.850-1.180mm) to Z100(0.100-0.150mm) and its

particle size distribution is more narrow and concentrated.

Different Application

Ceramic beads is widely used for surface finish in 3C products,medical implant...,while ceramic shot peening

is used for surface strengthening in aircraft and automobile industry such as aircraft structural parts,engines

and automobile mechanical parts

Different Production Cost

Ceramic shot peening has strict requirement of sphericity,then the qualified beads will be made through multiple

strict screening and selection in higher production cost compared with the one of ceramic beads.