ZIRNANO Ceramic Shot Peening Z210 Surface Strengthening Treatment For Aircraft Turbine Blades

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | Z850, Z600, Z425, Z300, Z210, Z150 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 12.5kgs/barrel, 25kgs (2 barrels)/paper carton, or 25kgs barrels +pallet |

| Delivery Time: | 5-10 days |

| Supply Ability: | 1500mt per year |

|

Detail Information |

|||

| Commodity Name: | Ceramic Beads Blasting Media | Chemical Index: | ZrO2 60-66%, SiO2 25-30%, Al2O3 7-13% |

|---|---|---|---|

| Manufacturing Process: | Melting Method | Bulk Density: | 2.3g.cm3 |

| True Density: | 3.85g/cm3 | Hardness: | 700HV |

| Package: | 25kgs Paper Cartons Or 25kgs Barrels +pallet | ||

| Highlight: | shot blasting material,shot blasting abrasive,abrasive shot blasting |

||

Product Description

ZIRNANO Ceramic shot peening Z210 surface strengthening treatment of aircraft turbine blades

![]()

The ceramic shot peening media also call ceramic beads, are zirconia based shot peening media, with ZrO2 60-66%, size from Z150 t0 Z850.

It’s superior to traditional peening media, like steel shots and glass beads, as it can achieve similar peening intensities with lower surface roughness, especially suitable for peening applications in the place of steel shots where ferrous contamination is not acceptable.

The features of Ceramic shot peening media are less abrasive breakdown and dust generation, resulting in a cleaner working environment and better operator visibility, mainly used for in aerospace industry, automotive industry and medical instrument.

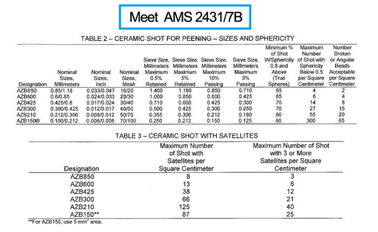

Our peening media ceramic shot meet the standard AMS 2431/7B.

![]()

| Chemical Index | ZrO2 | SiO2 | Al2O3 |

| 60-65% | 25-30% | 7-13% | |

| Typical Value | 62.20% | 26.10% | 9.05% |

| Bulk Density | 2.3g/cm3 | ||

| Specific Density | 3.85g/cm3 | ||

| Vickers Hardness | 700HV | ||

| Bead Size (mm) | Bead Size (mm) | ||

| Z150 | 0.15-0.21 | Z425 | 0.425-0.6 |

| Z210 | 0.21-0.30 | Z600 | 0.6-0.85 |

| Z300 | 0.30-0.425 | Z850 | 0.85-1.18 |

Special sizes available against clients’ requirement.

![]()

- High hardness, good elasticity and long service life

- Smooth surface finish that minimizes crack initiation

- Very low material abrasion that maintains accuracy of fine geometries

- High rebound that allows homogeneous coverage of intricate geometries

- No need for decontamination post-treatments for non-ferrous alloys

- High in price but low in cost. Can be recycling use and cost savings on the downstream processes (coating, polishing)

![]()

- Used for surface strengthening treatment of precision casting parts such as aircraft turbine blades and shafts, ordnance, and various spring gear hydraulic parts to eliminate internal stress.

- Used in the automotive industry for strengthening treatment to the surface of Shock absorber spring to improve its anti-fatigue performance

- Shot peening of gears, machined tools and other metal /alloy parts to eliminate stress and increase surface strength.

![]()

Free Samples -1kgs

Different blasting workpieces, Different requirements for ceramic beads.

Our factory can provide consult solution, suggest the ceramic beads sizes according to the workpiece you handle and provide 1kgs ceramic beads samples for free.

OEM customize same ceramic beads with your samples or requirements.

Our factory has our own test lab., with high precision chemical and particle size detection instruments. You can send ceramic beads samples, then we will test and analysis it and customize same ceramic beads with your samples or according to your customer requirements.

Quality Guarantee

Guarantee our ceramic beads has no quality problems, and in case any problems are found,

We accept return and/or exchange.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Caroline Cui

![]()

Address: Ximazhuang, Liuzhai Town, Xinmi City, Henan, China