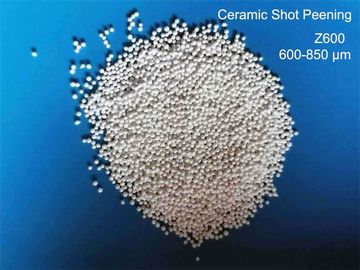

High Strength Ceramic Shot Peening Z600 600 - 850μM For Aerospace Industry

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | Z100-Z850 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kg barrel+pallet or 2*12.5kg barrel + Pallet |

| Delivery Time: | Within 3-5 days after order Confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 3000 MTS Per Year |

|

Detail Information |

|||

| Commodity: | Ceramic Shot Peening | Application: | Shot Peening |

|---|---|---|---|

| Mohs Hardness: | 8 Mohs | Bulk Density: | 2.3 G/cm3 |

| Particle Range: | 100-1180 μm | Specification: | Z100-Z850 |

| Vicker Hardness: | 700HV | Main Chemical: | 60-66% ZrO2 |

| Highlight: | shot blasting material,shot blasting abrasive,abrasive shot blasting |

||

Product Description

High strength Ceramic Shot Peening Z600 600-850μm, Z300 300-425 μm for Aerospace industry

1. Product Description of Ceramic Shot Peening

Ceramic Shot peening has higher hardness and strength as well as medium density due to its fine microstructure.

Then it will provide better wear resistance and impact resistance in whole peening process.

2. The comparation between Ceramic Shot Peening and Ceramic Beads Blasting

| Commodity | Main Chemical Index | Main Physical Index |

Ceramic Shot Peening &Ceramic Bead Blasting |

ZrO2 60-66% | Bulk Density: 2.3g/cm3 |

| SiO2 25-30% | True Specific Gravity: 3.85 g/cm3 | |

| Al2O3 7-13% | Vickers Hardness: 700 kg /mm2 | |

| Particle Size (Ceramic Shot Peening) |

Z100: 100-150μm | Z150: 150-210μm |

| Z210: 210-300μm | Z300: 300-425μm | |

| Z425:425-600μm | Z600: 600-850μm | |

| Z850: 850-1180μm | ||

| Remark: Special specification can be customized | ||

| Particle Size (Ceramic Bead Blasting) |

B20: 600-0.850μm | B100:106-0.180μm |

| B30: 425-600μm | B120: 63-125μm | |

| B40: 250-425μm | B170: 45-90μm | |

| B60: 150-300μm | B205: 0-63μm | |

| B80: 125-212μm | B400: 30-63μm | |

| Remark: Special specification can be customized | ||

Seen from the above chart,ceramic Shot Peening has the same chemical composition and properties as the

one of ceramic beads blasting media,while they have different standards in particle size distribution and spherity

to meet different applications in shot peening and blasting application.

3. Main Applications of Ceramic Shot Peening

Surface shotpeening forindustry such as aerosapce,landing gears, gear transmissions, engine blades etc

Surface Strengthening in automotive industry such as transmission gears, automotive aluminum wheels, shock

absorbers etc

![]()

4. How to use & store ceramic Shot Peening?

When using the ceramic shot peening,please wear protective equipments appropriately;

Avoid direct contact with eyes and skin;

Please wash hands with water and soap before eating, drinking and smoking;

Keep the container tightly closed and store it in a cool, dry warehouse

5. Why choose us?

Professional manufacturer of ceramic shot peening and ceramic beads to provide stable products with most

favorable price;

Certificated by ISO9001,ISO14001;

Products has already exported to Japan,Vietnam, USA, Russia,Poland,Taiwan Area etc.

The stable supplier of Foxconn,Samsung Electronics,Tongda Group etc.