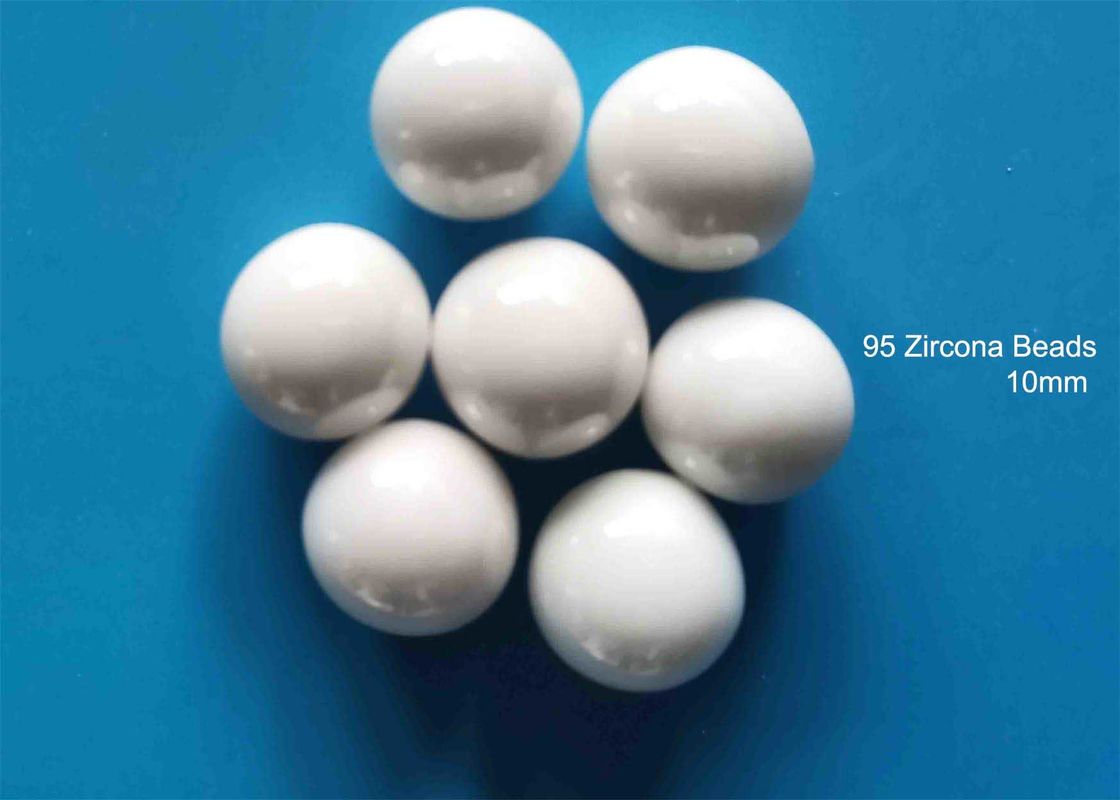

High Viscosity Zirconia Grinding Media Yttrium Stabilized Zirconium Oxide Beads

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | 0.2-10mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | Negotiable |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kg barrel+ Pallet |

| Delivery Time: | Within 3-5 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 500mt per Year |

|

Detail Information |

|||

| Commodity: | 95 Zirconia Beads | Product Name: | 95 Yttrium Stabilized Zirconia Beads |

|---|---|---|---|

| Usage: | Grinding Media For High Hardness And High Viscosity Slurry | Main Chemical: | 94.5% ZrO2 |

| Bulk Density: | 3.6g/cm3 | True Gravity: | 6.0 G/cm3 |

| Vicker Hardness: | ≥1100HV | Product Process: | Sintering |

| Highlight: | High Viscosity Zirconia Grinding Media,Zirconia Grinding Media 10mm,Yttrium Stabilized Zirconium Oxide Beads |

||

Product Description

95 Yttrium stabilized Zirconia Beads Grinding Media for High viscosity& High hardness materials

1. Product Description of 95 Zirconia Beads

The crystal structure of 95 zirconia beads is mostly Tetragonal Zirconium Polycrystal, so it is also called

as "TZP" zirconia beads, it selects the micron and sub-nano zirconium oxide and yttrium oxide as raw

materials, then sintered under high temperature, finally made into different size by special technology.

It is mainly used for the ultra-fine grinding and dispersion of high-viscosity and high-hardness materials

which requires zero pollution.

2. Main Technical Data of 95 Yttrium stabilized Zirconia Beads

| Main Chemical Index | ZrO2≥94.5% |

| Bulk Density | 3.6 g/cm3 |

| True Gravity | 6.0 g/cm3 |

| Bending strength | ≥900 Mpa |

| Compressive strength | 7500 Mpa |

| Hardness | 8.5-9 Mohs |

| Wear Abrasion Rate | 4 ppm/hr |

3. Main Features of 95 Zirconia Beads:

Good wear resistance,good liquidity;

High density, high grinding efficiency;

Zero pollution to the materials to be ground;

Good stability, acid and alkali corrosion resistance.

4. Main Applications of 95 Yttrium stabilized Zirconia Beads:

Grinding and dispersion of electronic materials such as BaTiO3, BaCO3, etc.

Ultrafine grinding of magnetic materials

Superfine dispersion and grinding of paints, inks and coatings

Ultrafine grinding and dispersion of medicine and cosmetics

![]()

5. Precautions for using 95 zirconia beads:

Select the suitable zirconia beads according to the viscosity, hardness, dispersed particle size and grinding

requirements of the grinding material;

Clean the inner wall of the grinder barrel before grinding

Put the grinding material into the grinder firstly, then put the right amount of zirconium beads.

Gradually add the zirconia beads after the grinder is running normally. The filling volume is generally 70%-85%

of the internal volume of the grinder barrel;

Do not run the grinder for a long time under the condition of lack of grinding material, otherwise the grinder is

easy to be damaged;

Suggest to refuel the new zirconium beads appropriately to ensure the quality and efficiency of the grinding after

the grinder has running for a long time

6. How to distinguish the normal abrasion and broken beads?

Generally speaking, the zirconia beads will become smaller when working for a period ,but still smooth in the

surface without edges and corners , which should be the wear of normal beads;

On the contrary, if there are angular, flake shaped beads in the beads, it should be broken beads.