95 Yttrium Stabilized Zirconia Grinding Media 6.0g/Cm3 For Minerals And Ores

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | 0.1mm-50mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | 25kgs |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 25kgs barrels+Pallet |

| Delivery Time: | 5-20 days |

| Supply Ability: | 500mt per year |

|

Detail Information |

|||

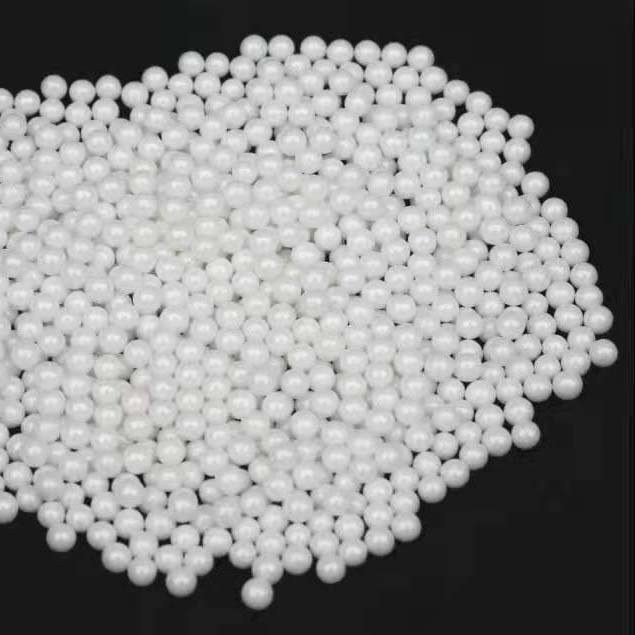

| Commodity Name: | Zirconia Milling Beads | Color: | Shiny White |

|---|---|---|---|

| Shape: | Sphere | Bulk Density: | 3.7g/cm3 |

| True Density: | 6.0g/cm3 | Harness: | 1100HV |

| Impact Strength: | 2.0KN | Abrasion Loss: | 0.5ppm/h |

| Chemical Index: | ZrO2 95%Min., Y2O3 4.5%Min. | Port Of Loading: | Tianjin/Qingdao, China |

| Package: | 25kgs Barrels+Pallet | Application: | Grinding Media For Battery, Magnetic Materials, Calcium Carbonate, Titanium Dioxide, Paint, Pigment, Dye, Ink. Etc |

| Highlight: | Yttrium Stabilized Zirconia Grinding Media,95 Zirconia Grinding Media,6.0g/Cm3 zirconia media |

||

Product Description

95 Ceramic beads Yttrium Stabilized Zirconia media Density 6.0g/Cm3 for minerals and ores

- DESCRIPTION

Yttrium Stabilized Zirconia media also called Ceramic beads , it is made of ultra-fine, high activity zirconia powder by sintering process, with Yttrium oxide as stabilizer and ZrO2 95% Min.

The beads is of low wear, and no pollution. Widely used in some minerals and ores, especially for non-metallic minerals.

- SPECIFICATION

Manufacturing process: Sintering Method

| Chemical composition | ZrO2 95% Min. Y2O3 4.5% Min |

| Color | Shiny white |

| Shape | Sphere/ Bead / Ball |

| Density | 6.0g/cm³ Min. |

| Specific density | 3.7g/cm³ Min. |

| Moh's hardness | 9 |

| Impact Strength | 2.9KN (2mm) |

| Compressive Strength | 5500MPa |

| Modulus of Elasticity | 200Gpa |

| Package | 25kg/barrel |

| SIZES Φ MM | ||||

| 0.1-0.2 | 0.2-0.3 | 0.3-0.4 | 0.4-0.6 | 0.6-0.8 |

| 0.8-1.0 | 1.0-1.2 | 1.2-1.4 | 1.4-1.6 | 1.6-1.8 |

| 1.8-2.0 | 2.0-2.2 | 2.2-2.4 | 2.4-2.6 | 2.6-2.8 |

| 2.8-3.0 | 4,5,6,7,8,9,10,12,15,17,20,25,30,40,50 | |||

- FEATURE

- High grinding efficiency: Due to the high density of zirconium oxide balls, it has a higher grinding kinetic energy at the same moving speed, and the grinding efficiency is 2-3 times higher than that of ordinary ceramic beads. You can get better results.

- Impact resistance, low wear: Due to the high content of ZrO2, high density, high toughness, low abrasion, no broken ball, peeling, etc., the dispersion of the abrasive is less polluted. The abrasion is 4-10 times lower than that of ordinary ceramic beads.

- Good stability: good stability, acid and alkali corrosion resistance.

- Good fluidity: good circularity, smooth surface, no pores, reflective gloss, easy to clean. The fluidity between the microbeads and the microbeads is good, and the wear on the equipment is small.

- Low cost of use: Zirconium oxide ball wear is the lowest in all grinding media. Zirconium oxide balls are high-strength, inert, hard, perfect, fine spherical particles.

- APPLICATION

95 Yttrium stabilied zirconia beads grinding media is waidely used for

Non-metallic minerals grinding.

Like Graphite ore, phosphate rock, kaolin, illite, magnesium hydroxide, quartz, mica

![]()

The 95 ceramic beads grinding media can make the ore grade purer and the particle size finer.