95% Zirconia Beads 2.0-2.2mm Zirconia Grinding Media High Strength Hardness

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | 0.2-60mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | 25kgs |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kgs Barrels+Pallet |

| Delivery Time: | 2-20 days |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 500mt per Year |

|

Detail Information |

|||

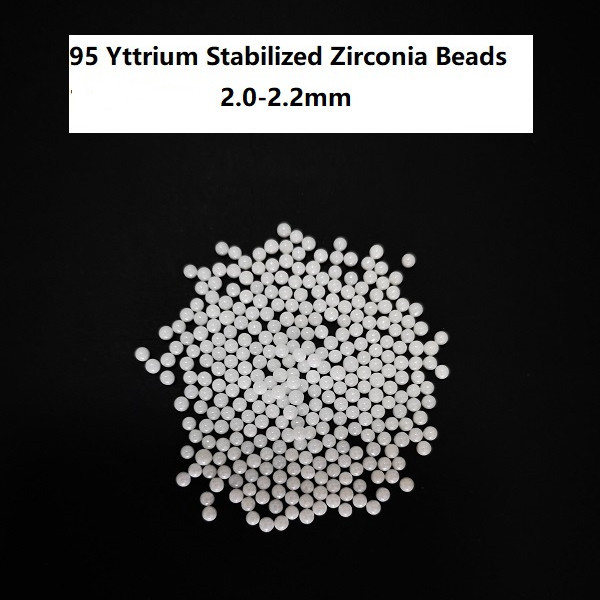

| Commodity Nam: | 95 Yttrium Stabilized Zirconia Beads | Color: | Milk White |

|---|---|---|---|

| Bulk Density: | 3.7g/cm3 | Impact Strength: | 2.0KN |

| Abrasion Loss: | 0.5ppm/h | True Density:: | 6.0g/cm3 |

| Highlight: | 95% Zirconia Beads,Zirconia Beads 2.0mm,2.2mm Zirconia Grinding Media |

||

Product Description

1. Product Description

95% zirconia beads are used for the extra-fine grinding of the material with Zero pollution and high viscosity and hardness, such as pesticide, electronic ceramics, magnetic materials, titanium pigment, medicine, food, pigment, paint, dye, ink and other chemical industrials.

2. Main Technical Data of 95 Ziconia Beads

| Commodity | Process | Physical Index |

| 95 Zirconia Beads Sintering Process |

ZrO2 ≥94.5% Y2O3 ≥5% Others ≤0.5% |

True Gravity≥6.0g/cm3 Bulk Density≥3.7g/cm3 Hardness :9 Mohs Compressive Strength≥2.0KN Φ2mm |

| size | Φ0.1-0.2mm,Φ0.2-0.3mm,Φ0.3-0.4mm,Φ0.4-0.6mm, | |

| Φ0.6-0.8mm,Φ0.8-1.0mm,Φ1.0-1.2mm,Φ1.2-1.4mm, | ||

| Φ1.4-1.6mm,Φ1.6-1.8mm,Φ1.6-1.8mm,Φ2.0-2.2mm, | ||

| Φ2.2-2.4mm,Φ2.4-2.6mm,Φ2.6-2.8mm ,Φ4mm,Φ5mm, | ||

| Φ6mm,Φ7mm,Φ8mm,Φ9mm,Φ10mm,Φ12mm,Φ15mm | ||

| Φ17mm,Φ20mm,Φ25mm,Φ30mm,Φ40mm,Φ45mm,Φ50m... | ||

| Special products can be customized | ||

3. Product Features

Good roundness, smooth surface, high density, high Strength

High strength and hardness

High Wear-resisting property

Low cost of use and best grinding media.

4. Application

1)Electronic ceramic,ink,paint,pigments,coating,dyes,food,cosmetic which require high wear resistance and contamination-free from grinding media

2)Nano particle size production industry.

5. Why choose us?

![]()