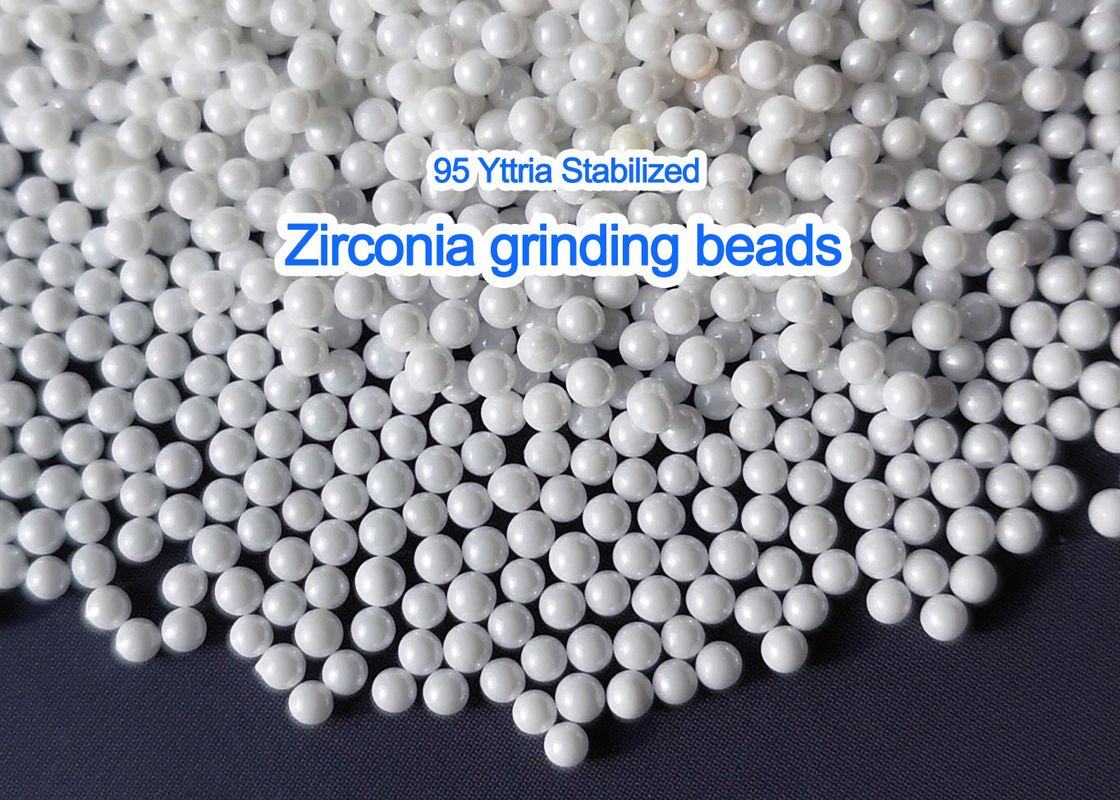

Yttrium Stabilized Zirconia Grinding Media Zirconia Grinding Beads For High Viscosity Slurry Grinding

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | 0.1mm-60mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | 25kgs |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 25kgs barrels+Pallet |

| Delivery Time: | 2-20 days |

| Supply Ability: | 3000mt per year |

|

Detail Information |

|||

| Commodity Name: | Zirconia Beads Grinding Media | Color: | White |

|---|---|---|---|

| Shape: | Sphere | Bulk Density: | 3.7g/cm3 |

| True Density: | 6.0g/cm3 | Harness: | 1100HV |

| Impact Strength: | 2.0KN | Abrasion Loss: | 0.5ppm/h |

| Package: | 25kgs Barrels+Pallet | Port Of Loading: | Tianjin/Qingdao, China |

| Highlight: | zirconium oxide beads,zirconium oxide balls,zirconia ceramic balls |

||

Product Description

![]()

Density 6.0g/cm3 Yttrium stabilized zirconia grinding beads for high viscosity slurry grinding

![]()

Zirconia grinding beads is made of ultra-fine, high activity zirconia powder by sintering process, with Yttrium

oxide as stabilizer and ZrO2 95% Min.

The beads are of fine grain, extreme density, anti-aging characteristics, low wear, and no pollution.

Widely used in the dispersion of middle or high viscosity slurry with different color requirements,

and different chemical conditions.

![]()

| Item | Parameters | Unit |

| Material | Yttrium stabilized Zirconia grinding meida | |

| Composition | ZrO2 94.8% Y2O3 5.2% | Wt% |

| Color | Shiny white | |

| Shape | Spherical (Roundness>95%) | |

| Bulk Density | ≥3.7 | Kg/L |

| Specific Density | ≥6.02 | g/cm3 |

| Size Range | 0.05mm,0.1mm,0.2mm,0.3mm,0.4mm,0.5mm,0.6mm, 0.7mm, 0.8mm, 0.9mm, 1.0mm, 1.2mm, 1.3mm, 1.5mm, 1.7mm, 2.0mm, 2.2mm, 2.6mm, 3.0mm | |

| Hardness(HV) | ≥1250 | Kg/mm2 |

| Elastic Modulis | 200 | Gpa |

| Crushing Load | ≥20(Φ7mm) | KN |

| Fracture Toughness | ≥9 | MPa.m1/2 |

| Wear | <10 (24hr) | ppm/hr |

| Application | Electric ceramic, Magnetic material, Zirconia, Silica, Zirconia Silicate, Titanium dioxide, Medical, Pigment, Dye, Ink, and Special chemical industry -GRINDING & DISPERSION | |

![]()

High grinding efficiency: Due to the high density of zirconium oxide balls, it has a higher grinding kinetic

energy at the same moving speed, and the grinding efficiency is 2-3 times higher than that of ordinary

ceramic beads. You can get better results.

Impact resistance, low wear: Due to the high content of ZrO2, high density, high toughness, low abrasion,

no broken ball, peeling, etc., the dispersion of the abrasive is less polluted. The abrasion is 4-10 times lower

than that of ordinary ceramic beads.

Good stability: good stability, acid and alkali corrosion resistance.

Good fluidity: good circularity, smooth surface, no pores, reflective gloss, easy to clean. The fluidity between

the microbeads and the microbeads is good, and the wear on the equipment is small.

Low cost of use: Zirconium oxide ball wear is the lowest in all grinding media. Zirconium oxide balls are

high-strength, inert, hard, perfect, fine spherical particles.

![]()

01 Electronic/Ceramic Slurry

02 Nano Materials/Magnetic/Rare-earth Material

03 Battery Material/Lithium Battery

04 Non-metallic mineral/ ground calcium carbonate

05 Titanium Dioxide

06Coating / ink /Dye/pigment

07 Medicine/Pesticides

08 Cosmetics

![]()

![]()

-

Horizontal sand mill,

-

Turbine horizontal sand mill,

-

Vertical sand mill,

-

Centrifugal sand mill,

-

Basket sand mill,

-

Ball mill, etc

![]()

![]()

![]()

![]()

Caroline Cui

![]()