1.8-2.0mm Zirconia Grinding Beads Zirconium Silicate Beads For Coating Paint

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | 0.1-50mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | Negotiable |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kg barrel+Pallet |

| Delivery Time: | 3-5 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 300mts per year |

|

Detail Information |

|||

| Commodity: | Zirconium Silicate Beads | Product Name: | 65 Zirconia Beads |

|---|---|---|---|

| Usage: | Grinding Media For Medium Viscosity Slurry | Color: | White |

| Shape: | Round Beads | Bulk Density: | 2.50g/cm3 |

| True Gravity: | 4.0g/cm3 | Vicker Hardness: | 700HV |

| Main Chemical: | 65% ZrO2 | ||

| Highlight: | 2.0mm Zirconia Grinding Beads,1.8mm Zirconium Silicate Beads,Zirconium Silicate Beads For Coating Paint |

||

Product Description

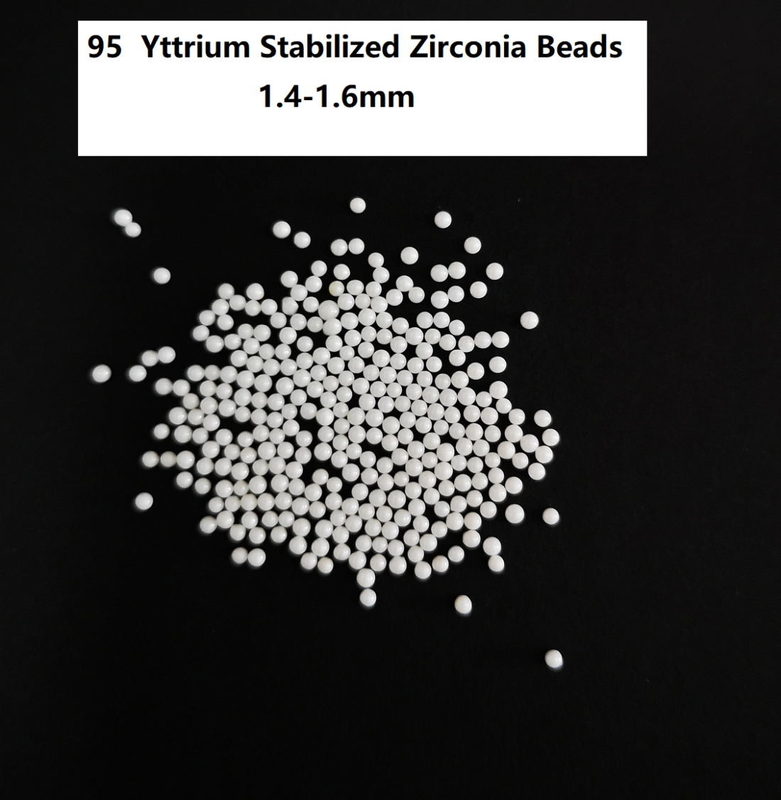

65 Zirconia Beads Grinding Media Zirconium Silicate Beads 1.8-2.0mm 2.0-2.2mm for Paint & Coating

1. Product Description of 65 Zirconia Beads

Zirconium silicate beads contain 65% ZrO2,so it is also called as 65 zirconia beads. It is made by special

baking and phasing process under high temperature,and there are no pores and cavities in the ball.

Zirconium silicate beads has medium density and hardness, suitable for dispersion and grinding of medium

and low viscosity slurry, which can match most sand mills.

2. Main Technical Data of 65 Zirconia Beads

| Commodity | Process | Chemical Index | Physical Index |

| 65 Zirconia Beads | Sintering | ZrO2 ≥ 65% | Bulk density:2.5g/cm3 |

| SiO2 25-30% | True Gravity ≥4.0 g/cm3 | ||

| Others ≤1.0% | Vicker Hardness≥700 HV | ||

| Particle Size(diameter) | 0.2-0.4mm 0.4-0.6mm 0.6-0.8mm,0.8-1.0mm, | ||

| 1.0-1.2mm,1.2-1.4mm,1.4-1.6mm,1.6-1.8mm,1.8-2.0mm | |||

| 2.0-2.2mm,2.0-2.5mm,2.5-3.0mm ,3.0-3.5mm | |||

| 4mm,5mm,6mm,7mm,8mm,10mm etc. | |||

| Remark: Special specification can be customized | |||

3. Main Applications of 65 Zirconium Silicate Beads

suitable for ultra-fine grinding of calcium carbonate, kaolin, titanium dioxide, coatings, magnetic coating,

paints, inks,metal ores etc.

4. Main Features of 65 Zirconia Beads

Uniform and dense crystal structure,which ensures the consistent fineness of grinding materials

Good toughness and impact resistance,which is little damage to grinding equipments

Low grinding cost compared with 95 zirconia beads

5. Applicable Equipments:

Vertical sand mill, horizontal sand mill, basket sand mill, ball mill, vibration mill etc

![]()

6. How and when to refuel the grinding beads?

It is known that there is natural loss of grinding beads in grinding process,then the particle size of beads

will become smaller and smaller. In order to maintain a uniform filling amount and avoid fine beads blocking

or entering the separation device, the broken beads shall be screened out and a certain amount of grinding

beads shall be supplemented according to the service life of the grinding machine and the conditions of its

own process. It is generally suggested to do the above work after 100-200 working hours.