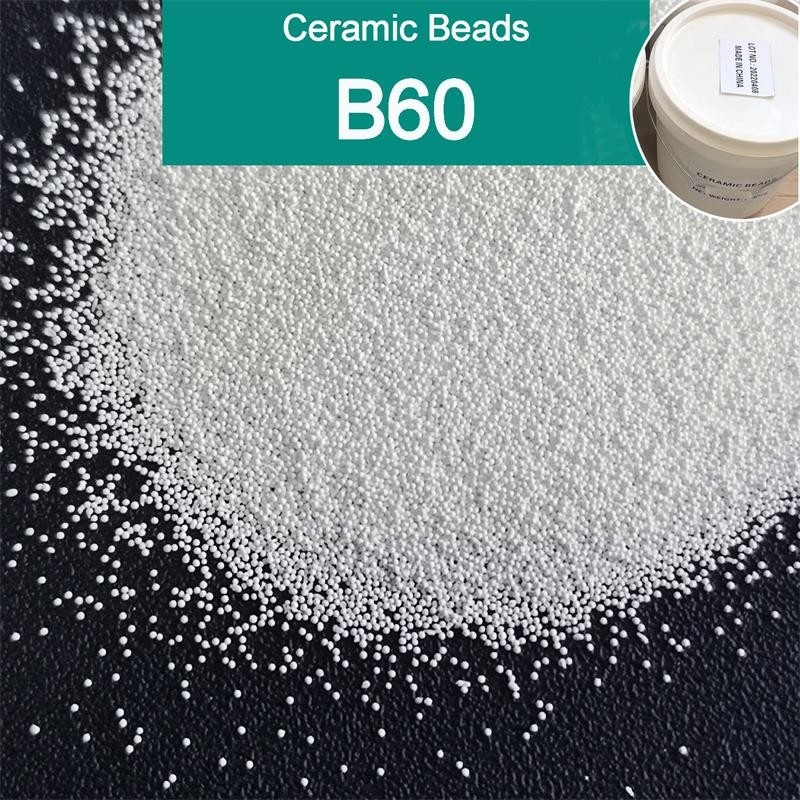

B60 Ceramic Beads Blasting Media For Steel Stainless Surface Better Gloss

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 12.5kgs/barrel, 25kgs (2 barrels)/paper carton, or 25kgs barrels +pallet |

| Delivery Time: | 5-10 days |

| Supply Ability: | 1500mt per year |

|

Detail Information |

|||

| Commodity Name: | Ceramic Beads | Chemical Index: | ZrO2 62%Min. |

|---|---|---|---|

| Manufacturing Process: | Melting Method | True Density: | 3.85g/cm3 |

| Bulk Density: | 2.30g/cm3 | Mohs Hardness: | 7 |

| Package: | 25kgs Paper Cartons Or 25kgs Barrels +pallet | Color: | White |

| Highlight: | B60 Ceramic Beads Blasting Media,Steel Stainless Surface Ceramic Blasting Media,ZrO2 62%Min Ceramic Blasting Media |

||

Product Description

Ceramic Beads Blasting Media B60 for steel stainless surface blasting better gloss

Product Description of Ceramic Beads

Ceramic beads blasting media is also called as ceramic blasting beads,it has the characteristics of good sphericity and

excellent chemically inert,most suitable for surface finish for metallic products.

Ceramic beads also has wide particle size,which can match most blasting machines. It is one clean and

popular blasting media.

Widely used as sandblasting abrasive in sandblasting machines for metal surface treatment,

including

Alu,

Alu alloy,

Titanium alloy,

Magnesium alloy,

Steel,

Stainless steel,

Copper etc.

Specification of Ceramic Beads

Manufacturing process: Melting method

| ZrO2 | SiO2 | Al2O3 | Other |

| 60-66%, | 25-30% max. | 7-13% max. | 5-8% |

| Color | Bulk Density | True Specific Density | Vickers Hardness |

| White | 2.3g/cm3 | 3.85g/cm3 | 700 HV |

Sizes Available

| B20 | B30 | B40 | B60 |

| B80 | B100 | B120 | B170 |

| B205 | B400 | Special sizes can be customized. | |

Features of Ceramic Beads

- High hardness and high toughness

- Good elasticity,Smooth surface

- Low break-down rate

- Little dust pollution

- More consistent blasting effect

Application of Ceramic Beads

Metal surface blast finishing

For Aluminum profiles, stainless steel, titanium magnesium alloy, knives, medical equipment, golf balls, etc

It is used to finish parts with high precision, small roughness Ra value and complex shape that are difficult to be completed by other processing methods.

Molds cleaning, such as glass bottle mold, tire mold, to ensure mold precision and improve product grade.

Surface balst Cleaning, clean the oxide skin, residual salt and welding slag of heat treated parts, weldments, castings, forgings, etc., and the cleaning quality can reach Grade Sa3.

Deburrs and clean the surface residues of machined parts.

Pretreatment before coating and plating to obtain active surface and improve adhesion of coating and plating.

It is used to improve the physical and mechanical properties of the workpiece surface, such as changing the surface stress state and improving the lubrication conditions of the mating parts.

Surface strengthening and stress removal.

Refurbishment of old parts.

Why Choose Ceramic Beads?

1. Better Gloss

Ceramic beads has good sphericity, smooth surface, good elasticity, good sandblasting effect and higher glossiness. It can restore the natural color of metal, form a smooth and non reflective finishing effect on the metal surface, improve the product appearance quality, and is especially suitable for the surface finishing of high-end products.

2. Suitable for alu alloy and titanium alloy

The density of ceramic beads is between glass bead and steel shot, which can obtain sand blasting effect that cannot be achieved by steel shot and glass bead, especially for nonferrous metal materials such as aluminum alloy and titanium alloy.

3. No dust

Ceramic beads no dust. This can effectively reduce the dust content in the working environment, effectively protect the environment and prevent pollution, without any harm to the health of workers.

4. Reduce cost

Ceramic beads has high hardness, long service life and good elasticity. It can be recycled for many times, which can effectively reduce the number of material changes and reduce the cost of workers.

5. Less energy consumption

Ceramic beads has higher density than glass beads, higher elastic modulus, and greater impact energy. Achieving the same shot peening effect in use can reduce the shot peening pressure, reduce energy consumption, and thus reduce production costs.

Standard packages of Ceramic Bead Blasting Media

25KG(12L) Round Barrel + Pallet

25KG(12L) Square Barrel + Pallet

25KG (12L) Barrel+ Wooden box

FAQ

1) Who we are ?

Professional manufacturer of ceramic beads, annual output over 3000mts with production base in Zhengzhou;

Top3 exporter of ceramic beads in China

2). How to Guarantee Quality?

Pre-production sample before mass production;

Inspection Report available for each shipment before loading;

3).How to get a sample?

We can provide samples before you place order. Sample is for free within 1 kgs, but shipping costs on you.

4). Why choose us

- ISO certificated.

- High quality-we guarantee all raw materials are original zircon sand imported from Australia. Refuse to use recycled raw materials.

- 15 years export experience team- Fast Response and Professional reassuring service

- Stable supplier of Foxconn,Samsung Electronics, Ujiden etc..

![]()