B40 Zirconia Ceramic Bead Blasting Media For Metal Surface Finish For Sandblasting Machine

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | Negotiable |

|---|---|

| Price: | Negotiable |

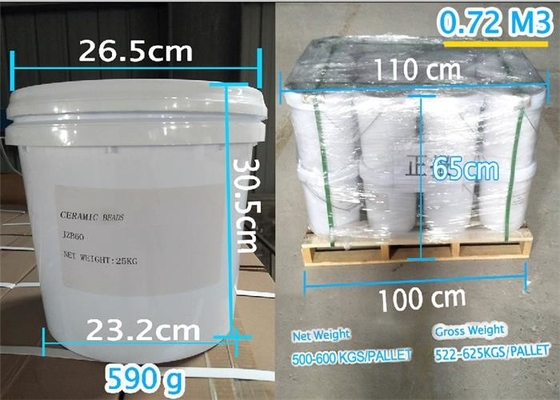

| Packaging Details: | 25kgs Barrels +pallet |

| Delivery Time: | 3-7 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 3000mts per year |

|

Detail Information |

|||

| Product Name: | Ceramic Blasting Media | Color: | White |

|---|---|---|---|

| Main Chemical: | ZrO2 60-66%,Al2O3 7-13%,SiO2 25-30% | Shape: | Round Solid Beads |

| Bulk Density: | 2.3g/cm3 | True Density: | 3.85g/cm3 |

| Hardness: | 700HV | Usage: | Blasting Media |

| Highlight: | B40 Zirconia Ceramic Bead Blasting,Metal Surface Ceramic Bead Blasting Media,Round Solid Ceramic Bead Blasting Media |

||

Product Description

1. Product Description of Ceramic Beads Grinding Media

Zirconia Ceramic beads selects the high quality zircon sand as main raw material, then fused in arc furnace under high temperature over 2000 degrees, its unique internal crystal phase provides its strong hardness and impact resistance. It is one round solid blasting media,with good sphericity and elasticity. Suitable for mental surface treatment,and various sandblasting machines.

2. Specification of Ceramic Blasting Media(Comparation between Ceramic Beads and Glass Beads)

|

Commodity Name |

Ceramic Blasting Beads |

Glass Beads |

|

Chemical Index |

ZrO2 60-66% |

SiO2:>65%,Na2O<14.0% |

|

Vickers Hardness |

≥700 HV |

≥560HV |

|

True Specific Gravity |

≥3.85 g/cm3 |

≥2.5g/cm3 |

|

Bulk Density |

≥2.3g/cm3 |

≥1.5g/cm3 |

|

Particle Size |

0.010-0.85mm |

0.001-0.850mm |

|

Usage |

Blasting Media |

Blasting Media |

|

Ferrous Contamination |

No Ferrous |

No Ferrous |

|

Dust Pollution |

Little |

Large |

|

Recyclable Times |

Multiple |

One time or twice |

|

Power consumption |

Low |

Low |

|

Equipment Wear Rate |

Low |

Low |

|

Blasting Effect |

High finish |

High finish |

|

Particle Size Comparation |

|

|

Ceramic Beads |

Glass Beads |

|

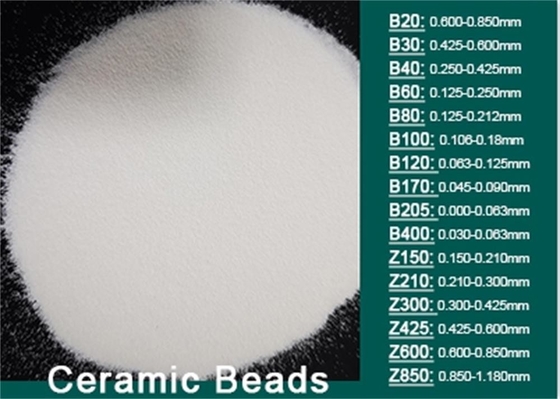

B20: 0.600-0.850mm |

30#:0.425-0.850mm |

|

B30:0.425-0.600mm |

40#: 0.425-0.600mm |

|

B40:0.250-0.425mm |

60#:0.300-0.425mm |

|

B60:0.150-0.300mm |

80#:0.150-0.300mm |

|

B80:0.125-0.212mm |

100#:0.106-0.212mm |

|

B100:0.106-0.180mm |

120#:0.106-0.150mm |

|

B120:0.063-0.125mm |

150#:0.075-0.150mm |

|

B150:0.000-0.125mm |

180#:0.075-0.106mm |

|

B170:0.045-0.090mm |

220#:0.053-0.106mm |

|

B205: 0.000-0.063mm |

280#:0.045-0.075mm |

|

B400: 0.030-0.063mm |

320#:0.001-0.050mm |

|

B505: 0.010-0.030mm |

/ |

|

Special Specification can be customized |

|

|

Workpiece |

Blasting media |

Consumption Monthly |

Dust |

Dust disposal cost |

|

Die-cast aluminum workpiece |

Glass beads 60# |

7 Tons |

Much |

High |

|

Ceramic beads B60 |

0.2 Tons |

Less |

Low |

So seen from above,Ceramic sand not only save monthly consumption cost and improve the work efficiency, ceramic beads has higher hardness, higher density,little dust pollution,which can be recycled in multiple, so ceramic beads are better grinding media than glass beads.

3. Main Application of Ceramic Beads Grinding Media

1)3C metal Products and accessories surface finish and cleaning;

2)Metal finish for aluminum parts,stainless steel parts,light alloys...

3) Surface blasting for rubber parts,plastic parts;

4) Mold-cleaning for glass-bottle,tires,die castings;

5)Surface preparation before anodizing,electroplating;

![]()

4. Storage, Package and Usage of Ceramic Beads

Ceramic beads should be stored in dry clean and ventilated indoor environment;

Kindly remind to wear masks and protective suit when using ceramic beads;

Normal package:25kg round barrel+pallet;

since ceramic beads need the wind to be recycled in the blasting process, so when using ceramic beads at the first time, please kindly open 1/3 to 1/2 vest of dust collector.