700HV B170 Zirconia Ceramic Bead Blasting For Mental Surface Finish

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | Negotiable |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kgs Barrels+Pallet |

| Delivery Time: | 3-10 days |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

|

Detail Information |

|||

| Product Name: | Zirconia Ceramic Blasting Media | Color: | White |

|---|---|---|---|

| Chemicals: | 60-66% ZrO2 | Bulk Density: | 2.3 G/cm3 |

| Specific Density: | 3.85g/cm3 | Vicker Hardness: | 700HV |

| Application: | Blast Cleaning, Surface Preparation, Surface Finishing And Shot Peening | Package: | 25kgs Barrels+Pallet |

| Highlight: | Surface Finish Zirconia Ceramic Bead Blasting,B170 Zirconia Ceramic Bead Blasting,700 HV Zirconia Ceramic Bead Blasting |

||

Product Description

1. Product Description

Ceramic beads blasting media also called zirconia ceramic beads, with ZrO2 60%-68%. It is made from zirconium sand, melting and blending in the high temperature mine heat furnace, then made to micro beads, obtained in melting method and then blowing into muciro beads. The sandblasting ceramic beads are no dust, durable and efficient, offering consistent surface finishing, are new eco-friendly blasting material, widely used for blasting and finishing, blast surface cleaning and surface preparation before coating.

It is mainly used in sandblasting machine, including Manual & Automatic sandblasting machine, Open type sandblasting machine and Sandblasting machine room, and shot peening equipment, etc.

2. Specification of zirconia ceramic beads balsting

|

ZrO2 |

SiO2 |

Al2O3 |

Other |

|

60-66%, |

25-30% max. |

7-13% max. |

5-8% |

|

Color |

Bulk Density |

True Specific Density |

Vickers Hardness |

|

White |

2.3g/cm3 |

3.85g/cm3 |

700 HV |

Sizes Available

|

B20 |

B30 |

B40 |

B60 |

|

B80 |

B100 |

B120 |

B170 |

|

B205 |

B400 |

Special sizes can be customized. |

|

3. Production Process of Ceramic beads blasing media

![]()

4. Features of Zirconia ceramic blasting media

1)High Hardness,Smooth Surface and Good roundness;

2)Low breakdown rate, High consistent blasting effect;

3)No Ferrous Contamination to the substrate material;

4)High Efficiency with low energy consumption compared to other abrasive materials;

5)No dust generation for a better work environment and operation.

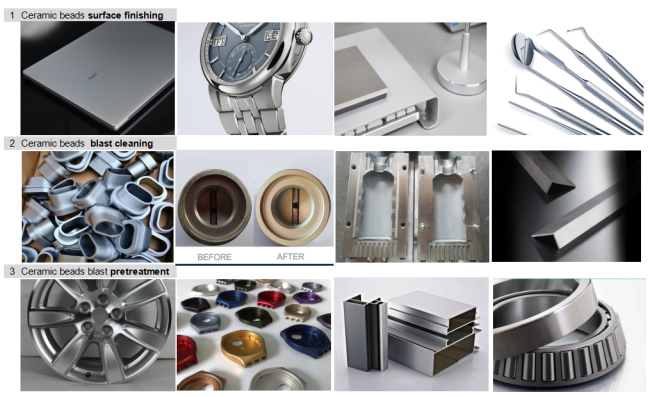

5. Application of Zirconia ceramic blasting beads

1)3C products blasting and finishing;

2)Sandblast cleaning for metal parts;

3)Descaling and deburring of steel surface;

4)Alu alloy and Stainless steel surface finishing