700HV Ceramic Beads Blasting Media 60 HRC B60 For Light Alloys

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | By negotation |

| Packaging Details: | 25kg barrel+ Pallet or 2*12.5kg barrel+Carton+Pallet |

| Delivery Time: | 3-5 days after order confirmed |

| Payment Terms: | L/C, , D/P, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability: | 3000 mts per year |

|

Detail Information |

|||

| Commodity: | Ceramic Blasting Media | Product Name: | Ceramic Beads |

|---|---|---|---|

| Usage: | Blasting Media | Color: | White |

| Material: | ZrO2 60-66%,SiO2 25-30%,Al2O3 7-13% | Hardness: | 700HV Or 60 HRC |

| Bulk Density: | 2.3g/cm3 | True Gravity: | 3.85g/cm3 |

| Specification: | B20-B505 | ||

| Highlight: | 60 HRC Ceramic Beads Blasting Media,zircon sand Ceramic Bead Blasting,Al2O3 ceramic bead abrasive |

||

Product Description

700HV Ceramic Beads Blasting Media B60 B80 B100 B120 B150 for Light Alloys

1. Product Description of Ceramic Beads

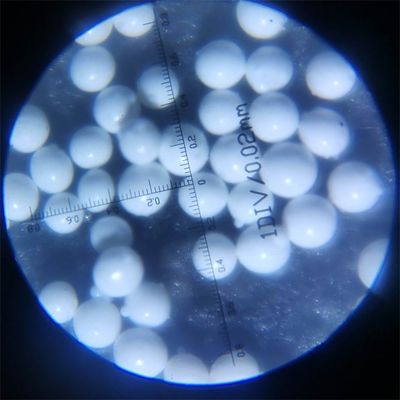

Ceramic beads selects the high quality zircon sand as main material, then fused in an arc furnace under

high temperature over 2000 degrees,finally made into different micro beads by special technology, it is one

white solid spherical blasting media.

Ceramic beads has wide particle size from B20(0.600-0.850mm) to B505(0.010-0.030mm),which can match

most blasting machine.

It has medium density,which are able to replace glass beads where one clean and bright blasting condition

is required,also can replace steel shot where one ferrous contamination is not allowed.

Ceramic beads is one clean and popular blasting media.

2. Main Technical Data of Ceramic Beads

| Commodity Name | Chemical Index | Physical Index |

Ceramic Beads |

ZrO2 60-66% SiO2 25-30% Al2O3 7-13% |

Vickers Hardness ≥700 HV Bulk Density≥2.3g/cm3 True Gravity: 3.85g/cm3 Process: Melting |

| Particle Size for Ceramic Blasting Media | ||

| B20: 600-850μm | B120: 63-125μm | |

| B30: 425-600μm | B150:0-125μm | |

| B40:250-425μm | B170: 45-90μm | |

| B60:150-300μm | B205: 0-63μm | |

| B80:125-212μm | B400: 30-63μm | |

| B100:106-180μm | B505: 10-30μm | |

| Particle Size for Ceramic Shot Peening | ||

| Z100: 100-150μm | Z150: 150-210μm | |

| Z210: 210-300μm | Z300: 300-425μm | |

| Z425:425-600μm | Z600: 600-850μm | |

| Z850: 850-1180μm | ./ | |

| Remark: Special specification can be customized. | ||

3. Main Features of Ceramic Beads

Smooth surface, high sphericity and good elasticity

High hardness, good toughness and high strength

More uniform blasting effect

No Ferrous contamination to the processed work-pieces

Low breakdown rate,little dust generated in blasting process

Save the treatment cost of solid waste

4. Main Applications of Ceramic Beads

Surface finish for aluminium parts,aluminium alloy,magnesium alloy,titanium alloy..

Mold cleaning for rubber molds,plastic molds,glass-bottle molds,tire molds...

Shot peening in automotive and aerospace industries.

5. Applicable Equipments

![]()

5. Why choose us?

Professional manufacturer of ceramic beads,annual output over 3000mts;

Stricter quality control system,each step can be traced from the raw material to finished products;

All shipment will be sampled and tested in twice even for one small sample;

Professional sales and technical staffs,providing 7*24hrs service support;

Quick response and fast delivery to meet customers’ requirements;

Stable supplier of Foxconn,Samsung Electronics(Vietnam),Kuhmichel...

Products are exported to USA,Canada,U.K.,New Zealand,Poland,Germany,Australia,India,Vietnam,

South Korea,Singapore,Malaysia,Philippines...