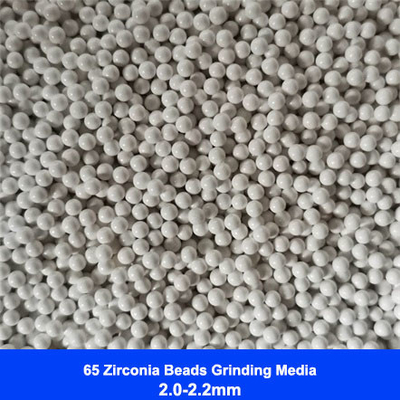

65 Zirconia Grinding Media Zirconium Silicate Beads 1.8-2.0mm 2.0-2.2mm For Paint

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | 0.2-50mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | Negotiation |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kg barrel + Pallet |

| Delivery Time: | Within 1-3 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 200mt |

|

Detail Information |

|||

| Commodity: | Zirconium Silicate Beads | Product Name: | 65 Zirconia Beads |

|---|---|---|---|

| Application: | Grinding Media | Process: | Sintering |

| Shape: | Round Solid Ball | Bulk Density: | 2.5g/cm3 |

| True Gravity: | ≥4.0 G/cm3 | Vicker Hardness: | ≥700 HV |

| Highlight: | 65 zirconia grinding balls,zirconia ceramic beads Media,zirconia ball mill grinding media |

||

Product Description

65 Zirconia Grinding Media Zirconium Silicate Beads 1.8-2.0mm 2.0-2.2mm for Paint

1. Product Description of Zirconium Silicate Beads(65 Zirconia Beads)

Zirconium silicate beads selects the high-purity ultra-fine zirconium silicate powder as raw materials, then

made into different size by special sintering process. Zirconium silicate beads contains 65% ZrO2, also

called as 65 zirconia beads.

It has uniform and dense microcrystal structure,which is one cost-effective grinding media compared with

95 zirconia beads.

2. Main Technical Data of Zirconium Silicate Beads (65 Zirconia Beads)

| Commodity | Process | Chemical Index | Physical Index |

|

Zirconium Silicate Beads (65 Zirconia Beads) |

Sintering | ZrO2 ≥ 65% | Bulk density:2.5g/cm3 |

| SiO2 25-30% | True Gravity ≥4.0 g/cm3 | ||

| Others ≤1.0% | Vicker Hardness≥700 HV | ||

| Particle Size(diameter) | 0.2-0.4mm 0.4-0.6mm 0.6-0.8mm,0.8-1.0mm, | ||

| 1.0-1.2mm,1.2-1.4mm,1.4-1.6mm,1.6-1.8mm,1.8-2.0mm | |||

| 2.0-2.2mm,2.0-2.5mm,2.5-3.0mm ,3.0-3.5mm | |||

| 4mm,5mm,6mm,7mm,8mm,10mm etc. | |||

| Remark: Special specification can be customized | |||

3. Main Features of Zirconium Silicate Beads

High sphericity and smooth surface;

Good toughness, high impact resistance;

Good stability, acid and alkali resistance;

High price/performance ratio;

little damage to the grinding equipments;

Zero contamination to the treated materials.

4. Main Applications of 65 Zirconia Beads

Mostly used in the grinding and dispersion of calcium carbonate, kaolin, titanium dioxide, pesticides,

inks, paints and coatings.

![]()

5. The difference between Zirconium Silicate Beads and Ceramic Beads Blasting Media

Firstly,produced by different process: Zirconium silicate beads is made by sintering process,while

ceramic beads is produced by melting process.

Secondly,different chemical composition: Zirconium Silicate Beads contains Min 65% ZrO2 and 25-30%

SiO2,while Ceramic beads contains 60-66% ZrO2,7-13% Al2O3 and 25-30% SiO2.

Thirdly,different particle size: Zirconium silicate beads has wide size from 0.2mm to 10mm,while ceramic

beads has narrow size from B20(0.600-0.850mm) to B505(0.010-0.030mm).

Fourthly,different applications: Zirconium silicate beads is one grinding media,equipped with sand mills,

while ceramic beads is one popular blasting media,matched with blasting machines.