95 YTZP Yttrium Stabilized Zirconia Grinding Media 7mm Density 6.0g/Cm3

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | 0.1mm-50mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | 25kgs |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 25kgs barrels+Pallet |

| Delivery Time: | 5-20 days |

| Supply Ability: | 500mt per year |

|

Detail Information |

|||

| Commodity Name: | Zirconia Milling Beads | Color: | Shiny White |

|---|---|---|---|

| Shape: | Sphere | Bulk Density: | 3.7g/cm3 |

| True Density: | 6.0g/cm3 | Harness: | 1100HV |

| Impact Strength: | 2.0KN | Abrasion Loss: | 0.5ppm/h |

| Chemical Index: | ZrO2 95%Min., Y2O3 4.5%Min. | Port Of Loading: | Tianjin/Qingdao, China |

| Package: | 25kgs Barrels+Pallet | Application: | Grinding Media For Battery, Magnetic Materials, Calcium Carbonate, Titanium Dioxide, Paint, Pigment, Dye, Ink. Etc |

| Highlight: | 95 YTZP Zirconia Grinding Media,7mm Zirconia Grinding Media,95 yttria stabilised zirconia |

||

Product Description

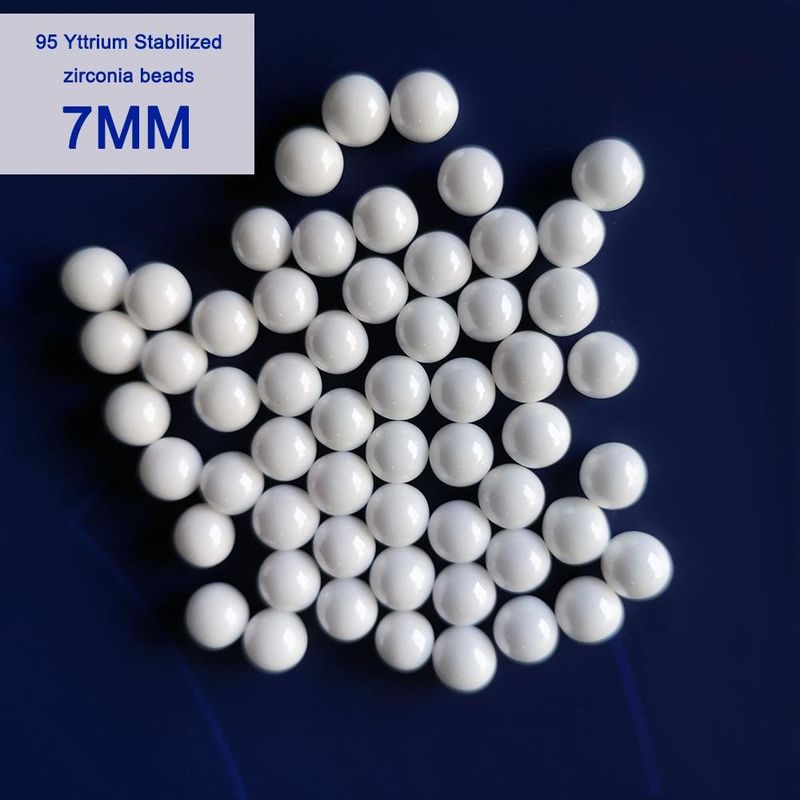

95 YTZP Yttrium Stabilized Zirconia Grinding balls size 7mm density 6.0g/cm3

- DESCRIPTION

Yttrium Stabilized Zirconia Balls also called Ceramic beads , it is made of ultra-fine, high activity zirconia powder by sintering process, adding Yttrium as stabilizer.

It is shiny white balls, with good roundness, high density, high grinding efficiency low wear and no pollution.

Widely used for wet and dry ultrafine dispersion and grinding of various slurry and powders that require refusal of cross-contamination.

- SPECIFICATION

Manufacturing process: Sintering Method

| Chemical composition | ZrO2 95% Min. Y2O3 4.5% Min |

| Color | Shiny white |

| Shape | Sphere/ Bead / Ball |

| Density | 6.0g/cm³ Min. |

| Specific density | 3.7g/cm³ Min. |

| Moh's hardness | 9 |

| Impact Strength | 2.9KN (2mm) |

| Compressive Strength | 5500MPa |

| Modulus of Elasticity | 200Gpa |

| Package | 25kg/barrel |

| SIZES Φ MM | ||||

| 0.1-0.2 | 0.2-0.3 | 0.3-0.4 | 0.4-0.6 | 0.6-0.8 |

| 0.8-1.0 | 1.0-1.2 | 1.2-1.4 | 1.4-1.6 | 1.6-1.8 |

| 1.8-2.0 | 2.0-2.2 | 2.2-2.4 | 2.4-2.6 | 2.6-2.8 |

| 2.8-3.0 | 4,5,6,7,8,9,10,12,15,17,20,25,30,40,50 | |||

FEATURE

- Good roundness, smooth surface, and bright.

- Good stability, strong acid and alkali resistance.

- Excellent toughness, compressive strength, impact resistance, no breakage, and less pollution to materials

- Low abrasion (ppm level), minimal wear on the equipment, and very low self-wear.

APPLICATION

1. Wear-resistant and corrosion-resistant products:

Inks (heat transfer inks, solvent inks, eco-solvent inks, digital printing paint inks, digital printing disperse dye inks, pigment inks, LED-UV special curing inks, water-based universal pigment inks, Coating inks, printing inks, pen inks), high-end pigments, high-end paints, coatings

2. High-strength, high-toughness products:

Magnetic materials, electronic components (ceramic variable vessels, thermistors, etc.), electronic materials (liquid crystal display color paste, plasma display glass paste, semiconductor polishing slurry, etc.).

3. Prevent pollution materials: Medicine, food and food additives, cosmetics.

4. Ceramics: Electronic ceramics, refractory ceramics, structural ceramics

5. New energy lithium battery industry:

Lithium iron phosphate, lithium titanate, graphite, silicon carbon, graphene, carbon nanotubes, alumina ceramic diaphragms, etc.

![]()

APPLICABLE EQUIPMENT

- Yttrium-stabilized zirconia beads is especially suitable for

- Nano-horizontal sand mills

- High-speed stirring mills

- Vibration mills

- Ultra-fine grinding and

- Various high-speed rod-pin sand mills, etc.;