88% Min Roundness Bead Blasting Beads B60 B80 B100 B120 For Stainless Steel Parts

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | By negotation |

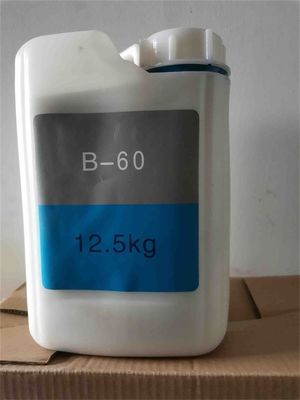

| Packaging Details: | 25kg barrel+ Pallet or 2*12.5kg barrel+Carton+Pallet |

| Delivery Time: | 3-5 days after order confirmed |

| Payment Terms: | L/C, , D/P, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability: | 3000 mts per year |

|

Detail Information |

|||

| Commodity: | Ceramic Blasting Media | Product Name: | Ceramic Beads,Zirconium Silicate Beads |

|---|---|---|---|

| Shape: | Beads | Color: | White |

| Material: | ZrO2 60-66%,SiO2 25-30%,Al2O3 7-13% | Hardness: | 60HRC Min |

| Bulk Density: | 2.3g/cm3 | True Gravity: | 3.85g/cm3 |

| Size: | B205 0-0.063mm | Free Sample: | Available |

| Highlight: | B60 Bead Blasting Beads,B80 Bead Blasting Beads,B100 industrial ceramic beads |

||

Product Description

88% Min Roundness Ceramic Beads Blasting Media B60 B80 B100 B120 for Stainless Steel Parts

1. Product Description of Ceramic Beads

Ceramic Beads is also called as zirconia sand, it selects the high quality zircon sand as main raw material,

then fused in electronic furnace under high temperature over 2000 degrees,finally made into different beads

accordingly.

it has the outstanding characteristics of good impact strength and toughness, high hardness and surface

smoothness. It can be recycled and reused,its service life can be prolonged more than 20 times compared

with the one of glass beads.

Ceramic beads is round solid beads,it has a wide range of particle size, which ensures it can be matched

with all types of sandblasting machines.

2. Main Technical Data of Ceramic Beads Blasting Media

| Commodity | Main Chemical Index | Main Physical Index |

|

Ceramic Bead Blasting |

ZrO2 60-66% | Bulk Density: 2.3g/cm3 |

| SiO2 25-30% | True Specific Gravity: 3.85 g/cm3 | |

| Al2O3 7-13% | Vickers Hardness: 700 kg /mm2 | |

|

Particle Size

|

B20: 0.600-0.850mm | B120: 0.063-0.125mm |

| B30: 0.425-0.600mm | B150:0.000-0.125mm | |

| B40: 0.250-0.425mm | B170: 0.045-0.090mm | |

| B60: 0.150-0.300mm | B205: 0.000-0.063mm | |

| B80: 0.125-0.212mm | B400: 0.030-0.063mm | |

| B100: 0.106-0.180mm | B505: 0.010-0.030mm | |

| Remark: Special specification can be customized | ||

3. Main Applications of Ceramic Beads

Ceramic beads has smooth surface and good elasticity,it can be bounded in multi-angles,especially suitable

for metal surface finish,such as aluminium alloy,magnesium alloy,titanium alloy,stainless steel products...

![]()

In addition,it also can be used for plastic and rubber products...

4. How to avoid the rusting problem during wet sandblasting?

There is no dust generated in whole wet blasting process,while mositure will make the surface rust again.

Then the solution is suggested to add 1% to 15% Anti-rust agent (trisodium phosphate, sodium carbonate,

sodium nitrite, etc.), emulsifier or soapy water to make the surface no longer rust in a short period , and

then apply maintenance primer;

5.The Popular Specification of Ceramic Beads

B40(0.250-0.425mm) for Molds-cleaning such as glass-bottle molds,tire-molds...

B60(0.150-0.300mm) for Surface finish of Stainless steel parts,outdoor fitness,rubber parts...

B100(0.106-0.180mm) for Surface finish of titanium alloy bicycle frame...

B120(0.063-0.125mm) for golf head,artifical joint,computer plastic cladding...

B170(0.045-0.090mm)B205(0-0.063mm) for 3C products such as the metal surface,its built-in

parts and its accessories....

6. Main Package of Ceramic Beads Blasting Media

25kg barrel+ Pallet,20 Barrels/500kgs per Pallet;

2*12.5kg barrel+ Carton+ Pallet,80 Barrels/40 Carton per Pallet;

Special Package can be Customized.

![]()