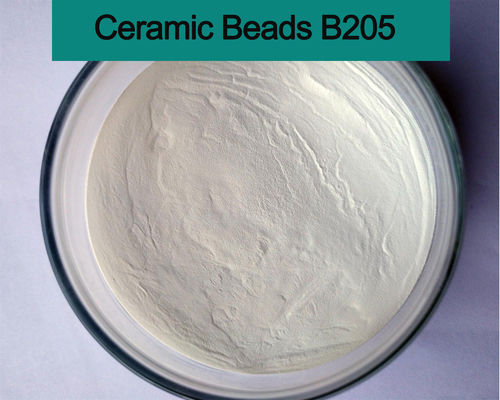

Fishing Reels Sandblasting B205 Ceramic Bead Blasting Media

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B205: 0.000-0.063mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 12.5kgs/barrel, 25kgs (2 barrels)/paper carton, or 25kgs barrels +pallet |

| Delivery Time: | 5-10 days |

| Supply Ability: | 1500mt per year |

|

Detail Information |

|||

| Commodity: | Ceramic Beads Blasting | Chemical Index: | ZrO2 60-66%, SiO2 25-30%, Al2O3 7-13% |

|---|---|---|---|

| Produce Process: | Melting Method | Bulk Density: | 2.3g.cm3 |

| True Density: | 3.85g/cm3 | Hardness: | 700HV |

| Package: | 25kgs Paper Cartons Or 25kgs Barrels +pallet | Free Sample: | Available |

| Highlight: | B205 Ceramic Bead Blasting Media,Reels Sandblasting Ceramic beads,700HV Ceramic Bead Blasting Media |

||

Product Description

B205 Ceramic Bead Blasting Media

DESCRIPTION OF CERAMIC BEADS BLASTING MEDIA

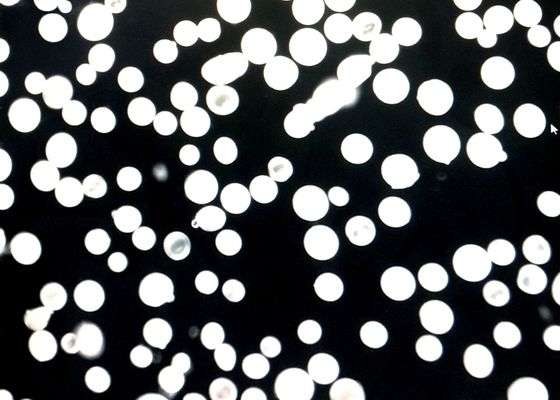

Ceramic bead blasting media is zirconium based ceramic beads, produced by melting process at more than 2000℃ temperature furnace , and then blow into micro beads B20-B505, It's with smooth surface, strong toughness, not easily broken, recyclable, and no dust pollution.

It is high quality sandblasting media for metal parts.

Main used for:

- Sandblasting satin finish

- Sandblasting cleaning

- Deburring

- Descaling

- Pretreatment before spraying/coating

- Shot peening

Applicable for Dry sandblasting, wet sandblasting, vapour blasting and microblasting, etc.

SPECIFICATION OF CERAMIC BEADS BLASTING MEDIA

| Chemical Index | ZrO2 | SiO2 | Al2O3 |

| 60-65% | 25-30% | 7-13% | |

| Typical Value | 62.20% | 26.10% | 9.05% |

| Bulk Density | 2.3g/cm3 | ||

| Specific Density | 3.85g/cm3 | ||

| Vickers Hardness | 700HV | ||

Particle Size Range

| B20: 0.600-0.850MM |

B120: 0.063-0.125MM |

| B30: 0.425-0.600MM |

B150: 0.053-0.106MM |

| B40: 0.250-0.425MM |

B170: 0.045-0.090MM |

| B60: 0.150-0.300MM |

B205: 0.000-0.063MM |

| B80: 0.125-0.212MM |

B400: 0.030-0.063MM |

|

B100: 0.106-0.180MM |

B505: 0.010-0.063MM |

FEATURES OF CERAMIC BEADS BLASTING MEDIA

1. High hardness, long life and good elasticity

The ceramic beads has high hardness, vickers 700HV.It ensures that the ceramic beads can

be shot peened for high-strength and ultra-high-strength structural parts. The small deformation ensures that

the shape of the projectile does not change during impact.

2. Recyclable and improving efficiency

Ceramic bead blasting media has long service life and high cost performance: The life of ceramic bead is more

than 20 times that of glass beads.

Ceramic beads not easy to be broken, and low wear, it can effectively reduce the materials replacement times

and reduce the cost of workers to improve efficiency.

APPLICATIONS OF CERAMIC BEADS BLASTING MEDIA

Metal fishing reels

Ceramic beads can be used for sandblasting for metal finishing reels to

- Eliminate defects such as scratches and abrasions on the surface of metal surface,

- Make the surface uniform,

- Obtain a matte decorative effect,

- Improving color adhesion.

![]()

Other application for

- Sandblasting finishing

- Surface cleaning

- Surface Pretreatment

- Renovation of old work parts etc..

For all below materials surface treatment:

- Aluminum

- Copper

- Stainless steel

- Aluminum alloy

- Magnesium alloy

- Titanium alloy, etc.

APPLICATION EQUIPMENT

Suitable sand blasting machine:

- Manual sand blasting machine,

- Automatic sand blasting machine,

- Open type series of sand blasting machine,

- Blasting room series.

FACTORY PRODUCTION

![]()

CONTACT US

To get price or more details about the ceramic beads blasting media. please send me inquiry by email or send message online...

Caroline Cui

Mob.: +86 15003865330

Email: caroline@zzztabrasive.com