Golf Head B205 Microblast Media Ceramic Bead Blasting

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiation |

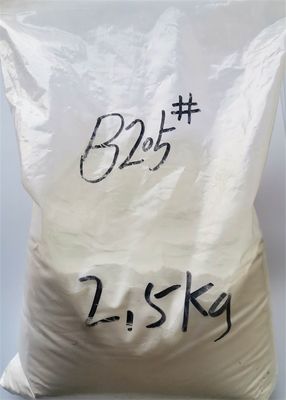

| Packaging Details: | 2*12.5kg Barrel+Carton Box+Pallet,25kg Barrel+Pallet |

| Delivery Time: | 3-7 days depending on the order quantity |

| Payment Terms: | L/C, T/T, Western Union,Paypal |

| Supply Ability: | 200mt per month |

|

Detail Information |

|||

| Product Name: | Ceramic Bead Blasting | Commodity: | Ceramic Microblst Beads |

|---|---|---|---|

| Specificaton: | B205 | Particle Size: | 0-0.063mm |

| Bulk Density: | ≥2.3g/cm3 | Shape: | Round Solid Beads |

| True Gravity: | 3.85g/cm3 | Hardness: | 643-785HV |

| Highlight: | Microblast Media Ceramic Bead Blasting,700HV Ceramic Bead Blasting,B205 Ceramic Bead Blasting |

||

Product Description

700HV Microblast Media Ceramic Bead Blasting B120 B170 B205 B400 B505 for Surface Finsh in

Golf Head

1. Product Description of Ceramic Bead Blasting

Ceramic Bead is also called as fused zircon sand, it is one clean and durable blasting media,which select

high quality imported zircon sand as main raw material,then fused in arc furnace,finally made into different

mircobeads through special technology.

Ceramic beads has higher density,hardness,lower break-down rate,its service life has been prolonged 20-25

times compared with galss beads.

It is one clean and durable balsting media,widely used in blasting applications.

2. Main Technical data

| Commodity | Chemical Index | ZrO2 60-66% SiO2 25-30% Al2O3 7-13% |

Ceramic Bead Blasting |

Processing Method | Melting |

| Vickers Hardness | ≥700 HV | |

| True Specific Gravity | ≥3.85 g/cm3 | |

| Bulk Density | ≥2.3g/cm3 | |

| Sphericity | ≥85% | |

| Particle Size | B20: 0.600-0.850mm | B120: 0.063-0.125mm |

| B30: 0.425-0.600mm | B150:0.000-0.125mm | |

| B40: 0.250-0.425mm | B170: 0.045-0.090mm | |

| B80: 0.125-0.212mm | B400: 0.030-0.063mm | |

| B100: 0.106-0.180mm | B505: 0.010-0.030mm | |

| Remark: Special specification can be customized | ||

3. Main Features of Ceramic Beads

Smooth surface,high hardness and strength,which will provide more consistent blasting effect;

Good toughness,low breakdown rate,which will save the production cost & provide one clean working condition;

No ferrous contamination to the treated parts or blasting equipment.

4. Main Applications

- Surface finish for golf head,artificial joint...

![]()

In addition,it is also used in:

- Metal surface finish for 3C products,its built-in parts as well as accessories.

- Surface cleaning for metal pipelines,moldings

- Deburring for Electronic components, heat-treated parts....

- Surface preparation before electroplating,anodizing...

5. Why Choose us?

- High cleanliness

All the beads is screened at least 6 times and clean-blowed through special technology.

- High Price/performance ratio

Our plant located in mountain areas,it has lower production cost and environmental protection cost,

then price is more competitive than the one of others'.

6. FAQ

Are you direct manufacturer ?

Yes,we have our own plant,we are direct manufacturer of ceramic beads.

Which one is more popular specification?

B40,B60,B120,B170,B205 is more popular specification.

How about the packages?

Our general package is 25kg round barrel+ pallet or 2*12.5kg suqare barrel+pallet.

Special package can be customized accordingly.

How about the MOQ?

MOQ is 25kg for air way,and 100kgs for sea way.

How to order the ceramic beads?

Please click the product photo and leave massage to us directly. We will send you the formal proforma

invoice ASAP.

What is your payment terms?

T/T,money gram, paypal is also available.

Can you provide free sample?

Yes,We can provide free sample.

Do you have the ISO certificate?

Yes,we have certificate of ISO9001,ISO14001.