10L 12Lbarrels package 700HV 25kgs 125ΜM JZB120 Ceramic Bead Blasting

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiable |

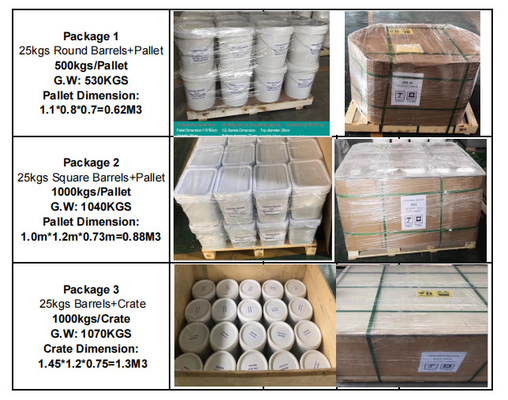

| Packaging Details: | 2*12.5kg barrel+ carton box + pallet or 25kg barrel+pallet |

| Delivery Time: | 3-5 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 200mts per month |

|

Detail Information |

|||

| Commodity: | Ceramic Blasting Beads | Product Name: | Ceramic Blasting Media |

|---|---|---|---|

| Usage: | Surface Finish For 3C Products | Bulk Density: | 2.3 G/cm3 |

| True Gravity: | 3.85 G/cm3 | Vicker Hardness: | 700HV |

| Main Material: | 60-66% ZrO2 | Package: | 25kgs Bucket+Pallet |

| Highlight: | B120 Ceramic Bead Blasting,125ΜM Ceramic Bead Blasting,10L Ceramic Bead Blasting |

||

Product Description

10L, 12L barrels packed 25kgs Ceramic media blasting beads B120 size 63-125 μm

DESCRIPTION

Ceramic beads is a kind of dust free sandblasting media. It’s manufactured by electric fusion at high temperatures more than 2000℃ in ore furnace, with main raw materials of Zirconia sands. Production process including smelting-flow into micro beads-screen- air cleaning and fine screen to different sizes from B20 to B505, and Z100-Z850.

The features of ceramic beads are spherical shape and good elasticity, suitable for complex workpieces. It is also of no metal pollution and dust free.

Applicable for sandblasting and forming of

- Steel;

- Stainless steel;

- Titanium alloy;

- Aluminum alloy;

- High temperature alloy

- Copper

- and other metals;

The ceramic beads is used for surface treatments like sandblast cleaning, deburring, pretreatment before coating and precise surface treatment .

It has concentrated grain sizes to obtain uniformity.

| Technical Data | |||

| Components | Content | CAS No. | EC No. |

| ZrO2 (Zirconium dioxide) | 60-68% | 1314-23-4 | 215-227-2 |

| SiO2 (Silicon dioxide) | 25-30 | 60676-86-0 | 262-373-8 |

| Al2O3 (Aluminum oxide ) | 7-13% | 1344-28-1 | 215-691-6 |

| Manufacturing Method | Melting in above 2000℃ furnace | ||

| True Density | 3.85 g/cm3 | ||

| Bulk Density | 2.3g/cm3 | ||

| Vicker Hardness | 700HV | ||

| Sizes for Sand Blasting | |||

| Bead Size | Size range | Bead Size | Size range |

| B20 | 0.60-0.85 mm | B120 | 0.063-0.125 mm |

| B30 | 0.425-0.60 mm | B125 | 0.000-0.125 mm |

| B40 | 0.24-0.425 mm | B170 | 0.045-0.090 mm |

| B60 | 0.125-0.25 mm | B205 | 0.000-0.063 mm |

| B80 | 0.18-0.25 mm | B400 | 0.030-0.063 mm |

| B100 | 0.125-0.18 mm | B505 | 0.000-0.030 mm |

| Sizes for Shot Peening | |||

| Z850 | 0.85-1.18 mm | Z210 | 0.21-0.30 mm |

| Z600 | 0.6-0.85 mm | Z150 | 0.15-0.21 mm |

| Z425 | 0.425-0.60 mm | Z100 | 0.10-0.15 mm |

| Z300 | 0.30-0.425 mm | ||

FEATURES

- High impact resistance and round beads, not easy to be broken. The broken rate of ceramic beads is around 1%.

- Low dust generation, friendly to the environment and worker’s health.

- Matte Metallic luster, no polishing reflective.

- No metal pollution.

APPLICATION

- · Sandblast cleaning for metal tools

- · Descaling and deburring

- · Alu alloy and Stainless steel surface satin finishing

- · Painting/ coating stripping and pre treatment before coating

The ceramic beads is applicable to use in the mobile open sandblasting machine.

![]()

![]()

CONTACT US

Other main sandblasting abrasive available

01. Ceramic Beads

02. Glass Beads

03. Steel Shot

04. Brown fused alumina

05. White fused alumina

06. Black fused alumina

We can provide MSDS, COA, CERTIFICATE OF ORIGIN, etc.

Contact us to get more details about ceramic beads and other sandblasting media, you can get very fast response and professional service.