65 HRC Mold Cleaning 2.3g/Cm3 B30 Ceramic Bead Blasting

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kg barrel+pallet or 2*12.5kg barrel+carton+pallet |

| Delivery Time: | 3-5 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 250mts monthly |

|

Detail Information |

|||

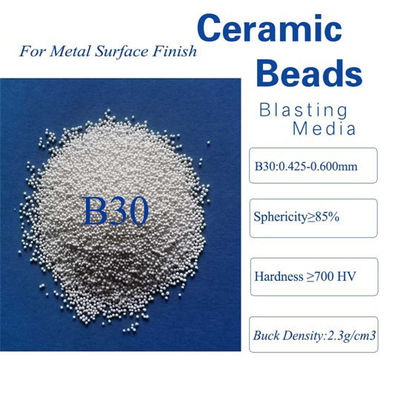

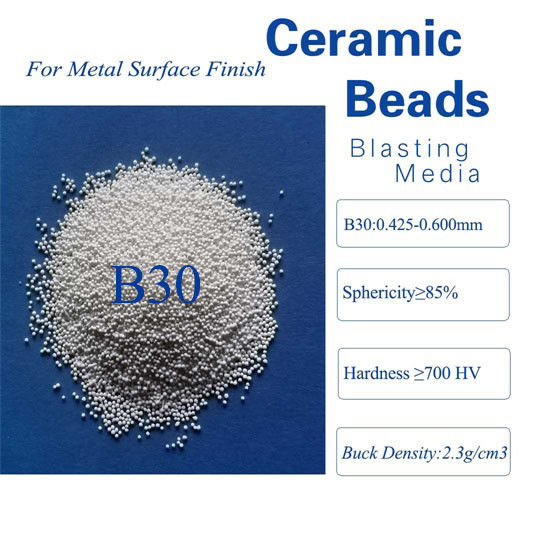

| Commodity: | Ceramic Bead Blasting | Product Name: | Ceramic Blasting Media,Ceramic Microspheres |

|---|---|---|---|

| Color: | White | True Gravity: | 3.85g/cm3 |

| Bulk Density: | 2.3g/cm3 | Hardness: | 50-65 HRC |

| Sphericity: | ≥85% | Usage: | Surface Cleaning,Surface Finish,Surface Preparation |

| Highlight: | B30 Ceramic Bead Blasting,Mold Cleaning Ceramic Bead Blasting,65 HRC Ceramic Bead Blasting |

||

Product Description

2.3g/cm3 Ceramic Bead Blasting Ceramic Shot Peening B20 B30 B40 B60 for Mold Cleaning

1. Product Description of Ceramic Bead Blasting

Ceramic beads is also called as zirconia sand,it selects the high quality zircon sand as main materials,then

fused in electric furnace under high temperature over 2000 degrees,then made into different microbeads

through special technology.

It can be used as blasting media or shot peening media according to different particle size distribution,here

we make one simple comparation between ceramic blasting media and ceramic shot peening(take

Saint-gobain’s Zirshot as an example) as below:

| Item | Zirnano Ceramic Beads | Zirshot(Saint-Gobain) |

| Chemical Index | ZrO2 60-66% SiO2 25-30% Al2O3 7-13% |

ZrO2 60-70% SiO2 28-33% Al2O3 <10% |

| Vickers Hardness | ≥700 HV | ≥700HV |

| True Specific Gravity | ≥3.85 g/cm3 | ≥3.85 g/cm3 |

| Bulk Density | ≥2.3kg/l | ≥2.3kg/l |

| Sphericity Standard | Length/Width Rate (0.70)≥85% | Length/Width Rate (0.80)≥65-80% |

| Particle Size | / | Z850 850-1180μm |

| B20 600-850μm | Z600 600-850μm | |

| B30 425-600μm | Z425 425-600μm | |

| B40 250-425μm | Z300 300-425μm | |

| B60 150-300μm | Z210 210-300μm | |

| B80 125-212μm | Z150 150-210μm | |

| B100 106-180μm | / | |

| B120 63-125μm | / | |

| B150 53-106μm | / | |

| B170 45-90μm | / | |

| B205:0-63μm | / | |

| B400:30-63μm | / | |

| B505:10-30μm | / | |

| Applications | Blasting Media | Shot Peening |

Seen from the above table, ceramic blasting media and shot peening has the same chemical comosition,

but in different size distribution,sphericity standard,when used in shot peening application,it requires higher

sphericity.

2. Application Comparations:

- Applications for Ceramic Blasting Media:

Surface Finish for Metal Parts;

Surface Finish for Plastic Parts;

Surface Finish for Rubber Parts.

![]()

- Applications for Ceramic Shot Peening

Shot Peening for metallic alloys;

Shot Forming for hard alloys.

![]()

3. Package:

25kg barrel+Pallet;

2*12.5kg barrel+ Carton+Pallet;

25kg barrel or 12.5kg barrel+ Wooden Box.

4. Applicable Equipment:

Manual sandblasting machine

Automatic sandblasting machine

Open type sandblasting machine

Sandblasting room

5. Questions(Q)&Answers(A):

Q: Are you direct manufacturer? How about your annual output?

A: Yes,we are direct manufactuer,our plant located in Shanxi,China.

Q: Do you provide free sample?

A: Yes,500g free sample is available.

Q: What is the popular specification of ceramic beads?

A: B40,B60,B120,B205 is the most popular specification.

Q: Which specification is widely used for stainless steel products?

A: B60,B120 is widely used for surface finish of stainless steel products.

Q: How about the delivery date?

A: For order quantity no more than 2mts, cargo can be deliveried within 3 days after order confirmed.

Q: How about the payment term?

A: T/T,LC,paypal,money gram are also acceptable.

Q: How about the max capacity in one pallet?

A: Gennerally speaking, the max loading capacity for one pallet is 20*25barrels/500kgs&40*25 carton/1000kgs.