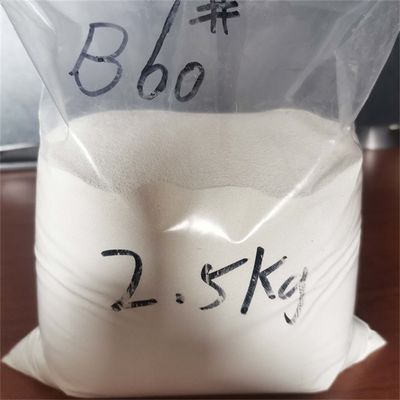

Spherical 700HV 0.3mm B60 Ceramic Bead Blasting Media

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 12.5kgs/barrel, 25kgs (2 barrels)/paper carton, or 25kgs barrels +pallet |

| Delivery Time: | 3-5 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 200mts per month |

|

Detail Information |

|||

| Commodity: | Ceramic Bead Blasting | Product Name: | Ceramic Beads |

|---|---|---|---|

| Shape: | Spherical | Bulk Density: | 2.3g/cm3 |

| True Gravity: | 3.85g/cm3 | Vicker Hardness: | ≥700HV |

| Sphericity: | ≥0.8 | Free Sample: | Available |

| Highlight: | B60 Ceramic Bead Blasting Media,700HV Ceramic Bead Blasting Media,Spherical Ceramic Blasting Media |

||

Product Description

Bright Satin Finish Ceramic Bead Blasting Media B60 for Stainless Steel Fitness Equipment

1. Product Description of Ceramic Beads

Ceramic beads are spherical shaped blasting media with high mechanical strength and low

breakdown rates.

It selects the high quality zircon sand as main raw material,then fused in arc furnace,finally made

into different micro beads through special technology.

Its chemical inert and low break down rate will finally provide one more consistent satin finish

effect.

2. Main Technical Data of Ceramic Beads Blasting Media

| Commodity | Chemical Index | Physical Index |

| Ceramic Beads | ZrO2 60-66% | Bulk density:2.3g/cm3 |

| SiO2 25-30% | True Gravity ≥3.85 g/cm3 | |

| Al2O3 7-13% | Vicker Hardness≥700 HV | |

| Specification | B20: 0.600-0.850mm | B120: 0.063-0.125mm |

| B30: 0.425-0.600mm | B170: 0.045-0.090mm | |

| B40: 0.250-0.425mm | B205: 0.000-0.063mm | |

| B60: 0.150-0.300mm | B400: 0.030-0.063mm | |

| B80: 0.125-0.212mm | B505: 0.010-0.030mm | |

| B100: 0.106-0.180mm | / | |

| Special specification can be customized | ||

3. Main Features of Ceramic Beads

High hardness,high mechnical strength;

Low breakdown rate,non ferrous contamination;

Good sphericity,smooth surface;

Low dust pollution,better blasting condition;

No hidden dangers of Silicosis.

4. Main Applications of Ceramic Beads for stainless steel surface finish:

Stainless steel tableware,shelfs,door handles,Lock cylinder,vacuum cup etc

Entertainment facilites ,fitness equipment indoor& outdoor such as children’s slide, two-person walker etc.

In addition,ceramic beads is also widely used in

metal surface finish such as 3C products,LCD TV frame as well as its accessories: power bank, USB data

cable,power plug...

Surface cleaning for glass-bottle molds,rubber molds,plastic molds,tire molds etc

Surface preparation before paiting or coating,plating,anodizing ect

Deburring for electronic products : circult board etc

Surface finish for medical parts: artifical joint, surgical instruments etc

Surface finish for golf club ....

![]()

5. Usage Precautions for glass beads and ceramic beads:

The proper blasting pressures for galss beads is 40-80 psi,it can be recycled 9-12 times;

While the requested blasting pressures for ceramic beads is 40-65 psi,its recycle life can be up to

70-90 times.

When using ceramic beads for the first time,it is suggested to open 1/3 to 1/2 vest of dust collector,

since ceramic beads need the wind to be recycled in the blasting process.

6. Why Choose us?

Professional manufacturer of ceramic beads,annual output over 3000mts;

Equipped with the advanced production line and testing equipments;

Professional sales team and quality staffs,providing prompt consulting service;

Products in stable quality and more competitive price/performance ratio;

Flexible delivery method and payment terms;

All the products will be double-sampled before shipment even for one sample in small quantity;

Quality can be traced from the very begining of raw materials to the final products;

Stable supplier of Foxconn,Samsung Electronics etc.