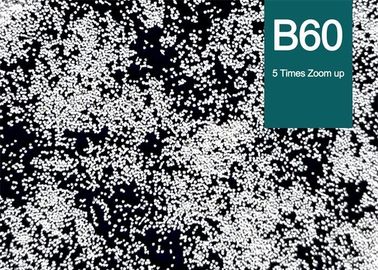

Aluminium Alloy Surface Sandblasting B60 size 0.150 to 0.300 Mm Ceramic Bead Blasting

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B60,B80 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiation |

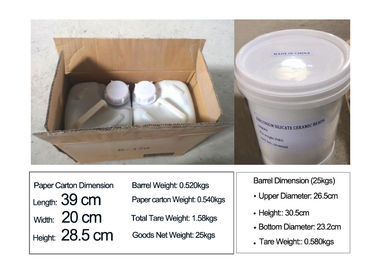

| Packaging Details: | 12.5kgs/barrel, 25kgs (2 barrels)/paper carton, or 25kgs barrels +pallet |

| Delivery Time: | 5-10 days |

| Supply Ability: | 1500mt per year |

|

Detail Information |

|||

| Commodity Name: | Ceramic Beads Blasting | Chemical Index: | ZrO2 60-66%, SiO2 25-30%, Al2O3 7-13% |

|---|---|---|---|

| Manufacturing Process: | Melting Method | Bulk Density: | 2.3g.cm3 |

| True Density: | 3.85g/cm3 | Hardness: | 700HV |

| Package: | 25kgs Paper Cartons Or 25kgs Barrels +pallet | ||

| Highlight: | B60 ceramic blasting media,0.300 Mm bead blasting beads |

||

Product Description

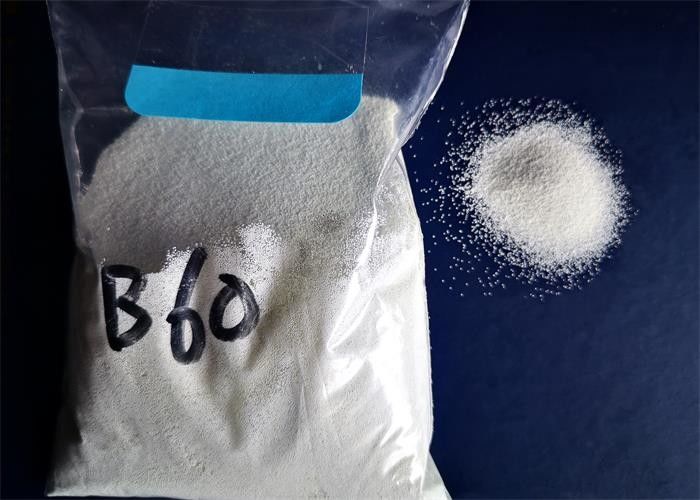

Ceramic Beads B60: 0.150-0.300 mm for Aluminium alloy surface sandblasting

DESCRIPTION OF CERAMIC BEADS

Ceramic beads blasting media is Zirconia based spherical blasting media, produced by melting process

at more than 2000℃ temperature , and then blow into micro beads B20-B505,

It's with true density 3.85 g/cm3, filling the gap between the high density of steel shots (7.8g/cm3) and the low density of glass beads (2.5g/cm3). It can reduce labor intensity of employees and is a new ideal alternative product of glass beads.

Mainly used for aluminium alloy metal surface treatment.

SPECIFICATION OF CERAMIC BEADS

| Chemical Index | ZrO2 | SiO2 | Al2O3 |

| 60-65% | 25-30% | 7-13% | |

| Typical Value | 62.20% | 26.10% | 9.05% |

| Bulk Density | 2.3g/cm3 | ||

| Specific Density | 3.85g/cm3 | ||

| Vickers Hardness | 700HV | ||

| Grit size | B20 | B30 | B40 | B60 | B80 | B100 | B120 |

| Microns μm | 600-850 | 425-600 | 250-425 | 125-250 | 180-250 | 125-180 | 63-125 |

| Grit size | B125 | B170 | B205 | B400 | B505 |

Special sizes can be customized |

|

| Microns μm | 0-125 | 45-90 | 0-63 | 30-63 | 0-63 | ||

| Grit size | Z850 | Z600 | Z425 | Z300 | Z210 | Z150 | Z100 |

| Microns | 850-1180 | 600-850 | 425-600 | 300-425 | 210-300 | 150-210 | 100-150 |

FEATURES OF CERAMIC BEADS

- Spherical beads and Smooth surface, leading uniform and shiny metal surface.

- Strong toughness, not easily broken, can be recyclable for multi-times, with high cost perfermance.

- No dust pollution, eco-friendly sandblasting media.

APPLICATION OF CERAMIC BEADS

Aluminium alloy parts metal surface treatment

The mobile phone aluminum alloy is synthesized by a special material processing technology. The ceramic sandblasting beads has a smooth surface, high hardness and strong toughness, not easily broken, and can be recycled multi-times, and has no dust pollution. Comparing with other blasting media, the utilization rate has been significantly improved.

Take the mobile middle frame for example, the ceramic beads is sprayed on the surface of the aluminum alloy mobile middle frame via the sandblasting machine to remove the oxide scale and burr residue. At the same time, the finer ceramic beads like B170 or B205 is used to finish the surface, remove the fine lines, and restore the fine and consistent metallic luster...

![]()

APPLICABLE EQUIPMENT

- In sandblasting-Wet & Dry sandblasting mechine

Manual sandblasting machine

Automatic sandblasting machine

Open type sandblasting machine

Sandblasting machine room

CONTACT US

No matter you’re the abrasive trader, distributor, the end users, blasting service suppliers, sandblasting equipment dealers or other blasting abrasive distributors, welcome to contact us. More details of ceramic blasting beads, updated prices and samples will be available.

Mob.: +86 15003865330