Wet sandblasting media Ceramic Bead B40 250-425μm for titanium alloy surface treatment

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B60,B80 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiation |

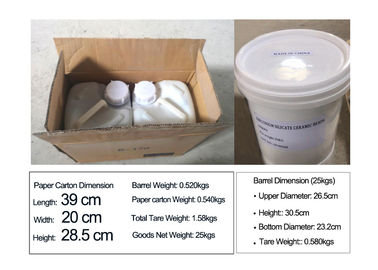

| Packaging Details: | 12.5kgs/barrel, 25kgs (2 barrels)/paper carton, or 25kgs barrels +pallet |

| Delivery Time: | 5-10 days |

| Supply Ability: | 1500mt per year |

|

Detail Information |

|||

| Commodity Name: | Ceramic Beads Blasting | Chemical Index: | ZrO2 60-66%, SiO2 25-30%, Al2O3 7-13% |

|---|---|---|---|

| Manufacturing Process: | Melting Method | Bulk Density: | 2.3g.cm3 |

| True Density: | 3.85g/cm3 | Hardness: | 700HV |

| Package: | 25kgs Paper Cartons Or 25kgs Barrels +pallet | ||

| Highlight: | abrasive media blasting,low dust blasting media |

||

Product Description

Zirconia Ceramic Bead Blasting B60 easy to clean after sandblasting

DESCRIPTION

Our ceramic bead blasting is kind of Zirconia ceramic blasting media, with ZrO2 60-66%, size from B20 to B505,

Mainly used as sandblasting media, including dry sandblasting and wet blasting

Tthe appearance or shape of the workpiece surface changes to obtain a certain degree of cleanliness and different roughness,

improve the mechanical properties of the workpiece surface, improve the fatigue resistance of the workpiece, increase the adhesion between the coating and extend the durability of the coating film.

SPECIFICATION

| Chemical Index | ZrO2 | SiO2 | Al2O3 |

| 60-65% | 25-30% | 7-13% | |

| Typical Value | 62.20% | 26.10% | 9.05% |

| Bulk Density | 2.3g/cm3 | ||

| Specific Density | 3.85g/cm3 | ||

| Vickers Hardness | 700HV | ||

| Grit size | B20 | B30 | B40 | B60 | B80 | B100 | B120 |

| Microns μm | 600-850 | 425-600 | 250-425 | 125-250 | 180-250 | 125-180 | 63-125 |

| Grit size | B125 | B170 | B205 | B400 | B505 |

Special sizes can be customized |

|

| Microns μm | 0-125 | 45-90 | 0-63 | 30-63 | 0-63 | ||

| Grit size | Z850 | Z600 | Z425 | Z300 | Z210 | Z150 | Z100 |

| Microns | 850-1180 | 600-850 | 425-600 | 300-425 | 210-300 | 150-210 | 100-150 |

FEATURES

1. High hardness, long life and good elasticity

The zirconia sand ceramic beads has high hardness, vickers 700HV.It ensures that the ceramic beads can be shot peened for high-strength and ultra-high-strength structural parts. The small deformation ensures that the shape of the projectile does not change during impact.

2. Recyclable and improving efficiency

Ceramic bead blasting media has long service life and high cost performance: The life of ceramic bead is more than 20 times that of glass beads.

Ceramic beads not easy to be broken, and low wear, it can effectively reduce the materials replacement times and reduce the cost of workers to improve efficiency.

APPLICATION

Processing material:

- Plastic

- Aluminum

- Copper

- Stainless steel

- Aluminum alloy

- Magnesium alloy

- Titanium alloy, etc.

Application industry

- 3C industry

- Aerospace

- Automotive industry

- Copper pipes and steel pipes

- Molds industry

- Golf

- Kitchenware

- Medical devices

- Other metal, alloy workpieces, castings and forgings

APPLICABLE EQUIPMENT

- In sandblasting-Wet & Dry sandblasting mechine

Manual sandblasting machine

Automatic sandblasting machine

Open type sandblasting machine

Sandblasting machine room

![]()

![]()

CONTACT US

No matter you’re the end users, blasting service suppliers, sandblasting equipment dealers or ceramic

blasting media and other blasting abrasive distributors, welcome to contact us. More details of ceramic

blasting beads, updated prices and samples will be available.