B30 0.425mm Ceramic Beads Blasting For AAU Heat Dissipation Shell

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiation |

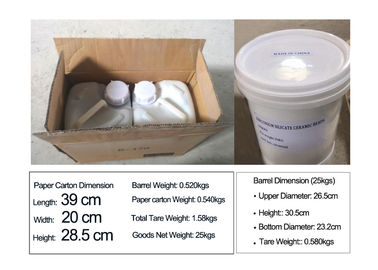

| Packaging Details: | 12.5kgs/barrel, 25kgs (2 barrels)/paper carton, or 25kgs barrels +pallet |

| Delivery Time: | 5-10 days |

| Supply Ability: | 1500mt per year |

|

Detail Information |

|||

| Commodity Name: | Ceramic Beads Blasting Media | Chemical Index: | ZrO2 60-66%, SiO2 25-30%, Al2O3 7-13% |

|---|---|---|---|

| Manufacturing Process: | Melting Method | Bulk Density: | 2.3g.cm3 |

| True Density: | 3.85g/cm3 | Hardness: | 700HV |

| Highlight: | smooth surface Ceramic Beads Blasting,no iron pollution Ceramic Beads Blasting,Heat Dissipation Shell Ceramic Bead Blasting |

||

Product Description

Ceramic beads B30 0.425-0.600mm for AAU heat dissipation shell of 5G base station

DESCRIPTION

Ceramic beads is a Zirconia based spherical blasting media, with smooth surface and good elasticity, no iron polution, and can be recycled multi time. It performs efficiently both in dry or wet blasting equipment.

Ceramic beads is mainly used for:

- Sandblasting satin finish

- Sandblasting cleaning

- Deburring

- Descaling

- Pretreatment before spraying/coating

- Shot peening

SPECIFICATION

| Product | Process | Specific Density | Bulk Density | Vickers Hardness |

| Ceramic beads | Electro-fusing | 3.85 (g/cm³) | 2.3 (g/cm³) | 700 HV |

| Chemical Components | ZrO2 60-62% | SiO2 25-30% | Al2O3 7-13% | Other 1% Max. |

| Size Available (mm) |

Blasting-clean/Surface finish | Shot peening | ||

| B20: 0.600-0.850mm | Z150: 0.150-0.210mm, | |||

| B30: 0.425-0.600mm | Z210: 0.210-0.300mm | |||

| B40: 0.250-0.425mm | Z300: 0.300-0.425mm, | |||

| B60: 0.125-0.250mm | Z425: 0.425-0.600mm, | |||

| B80: 0.125-0.212mm | Z600: 0.600-0.850mm | |||

| B100: 0.106-0.18mm | Z850:0.850-1.180mm | |||

| B120: 0.063-0.125mm | Other sizes can be customized against customers’ requirement. | |||

| B170: 0.045-0.090mm | ||||

| B205 : 0.000-0.063mm | ||||

| B400: 0.030-0.063mm | ||||

FEATURES

(1) Surface treatment consistency

Consistency of metallic light, the blasting strength is as good as steel balls processing effect, much higher than the glass beads strength. And can achieve adequate metal depth.

(2) Environmental Friendly

Low crushing rate, no dust, uniform particle size, high wear resistance, re-elasticity, no hidden danger of silicosis, it is harmless to the human body.

(3) Low equipment loss

Ceramic sand has smooth surface, high sphericity, good elasticity and low wear, can protect the equipment, whether it is dry spray or wet spray.

APPLICATION

Ceramic beads can be used for sandblasting cleaning of pre-treatment for AAU heat dissipation shell of 5G base station structure heat dissipation module assembly,

The large parts of the AAU shell are mainly prepared by die-casting aluminum alloy. The ceramic sand can be used as pretreatment and surface treatment blasting materials, so that the surface of the workpiece can obtain a certain degree of cleanliness and different roughness, and the mechanical performance of the surface of the workpiece can be improved. It can also achieve matt effect.

![]()

APPLICABLE EQUIPMENT

Manual sandblasting machine, automatic sandblasting machine, open sandblasting machine & sandblasting room

WHY CHOOSE US

1. Supply full sizes of ceramic blasting beads.

2. Quality Assurance- SGS certified and Provide Factory Test report each shipment.

3. ISO 9001 & ISO14001 Certified.

4. Good presale and after sale service-1 kg free samples, MSDS, TDS, COA. Fast online price quotation.

Rest assured order follow-up. Fast complain response within 24 hours if any.