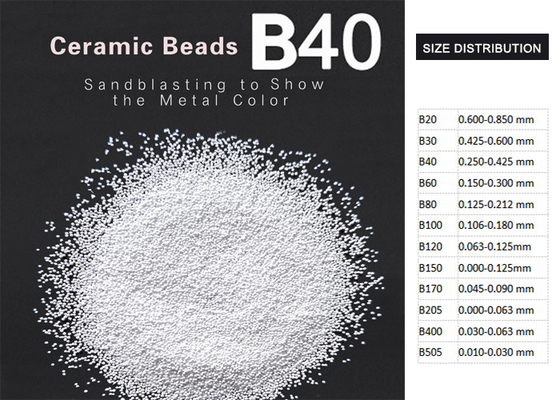

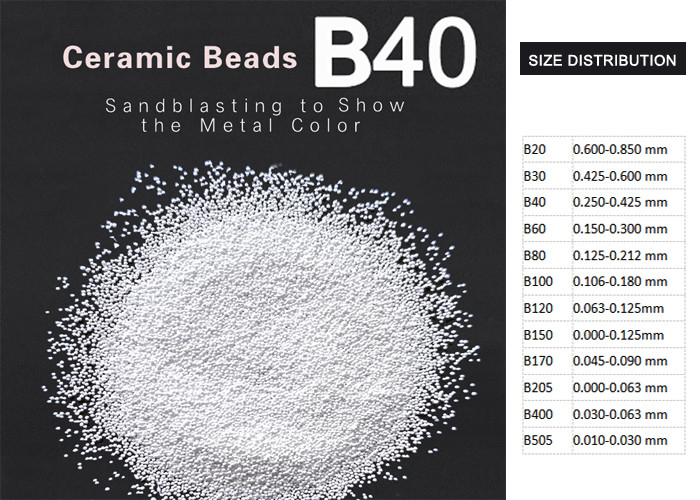

B40 Ceramic Beads Blasting Media For Turbo Diesel Surface Treatment

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 12.5kgs/barrel, 25kgs (2 barrels)/paper carton, or 25kgs barrels +pallet |

| Delivery Time: | 5-10 days |

| Supply Ability: | 1500mt per year |

|

Detail Information |

|||

| Commodity Name: | Ceramic Beads Blasting Media | Chemical Index: | ZrO2 60-66%, SiO2 25-30%, Al2O3 7-13% |

|---|---|---|---|

| Manufacturing Process: | Melting Method | Bulk Density: | 2.3g.cm3 |

| True Density: | 3.85g/cm3 | Hardness: | 700HV |

| Package: | 25kgs Paper Cartons Or 25kgs Barrels +pallet | ||

| Highlight: | abrasive media blasting,low dust blasting media |

||

Product Description

B40 Ceramic beads blasting media for turbo diesel surface treatment

DESCRIPTION OF CERAMIC BEADS B40

Ceramic beads blasting media is applicable for sandblasting surface treatment in automobile industry, like welding repair of automobile wheels, aluminum alloy wheel surface pretreatment, turbine blasting, motor polishing, motor refurbishment, shock absorber spring surface treatment, strengthening treatment etc..

Manufacturing process: Melting method

| ZrO2 | SiO2 | Al2O3 | Other |

| 60-66%, | 25-30% max. | 7-13% max. | 5-8% |

| Color | Bulk Density | True Specific Density | Vickers Hardness |

| White | 2.3g/cm3 | 3.85g/cm3 | 700 HV |

Sizes

| B20 | B30 | B40 | B60 |

| 600-850µm | 425-6000µm | 0250-425µm | 125-250µm |

| B80 | B120 | B170 | B205 |

|

125-212µm |

63-125µm | 45-90µm | 0-63µm |

Special sizes available against clients’ requirement.

PRODUCTION PROCESS OF CERAMIC BEADS B40

![]()

FEATURES OF CERAMIC BEADS B40

| 1. The ceramic beads is spherical, the surface is smooth and does not damage the work piece, high hardness, long life, good elasticity. During the blasting process, the particles rebound at multiple angles, very suitable for complex metal work pieces. |

| 2. Ceramic Beads can be reused, reducing the replacements times and improving production efficiency. Not easy to break, no dust, no metal pollution, clean and environmentally friendly, and no hidden dangers of silicosis, which is helpful to the health of employees. |

| 3. Comparing with the glass beads, the level of finish is higher, and the life is increased by about 20-30 times |

| 4. Comparing with steel shot, the roughness of ceramic beads is lower, the work piece is free of iron element pollution, no metal powder is left on the surface , and keep metallic color. |

APPLICATION OF CERAMIC BEADS B40

| Welding repair of automobile wheels--Sandblasting process to clean up stubborn dirt on the hub. |

| Aluminum alloy wheel surface pretreatment--Sandblasting before painting |

| Turbine blasting-Turbocharger housing surface treatment |

| Motor refurbishment-Sand blasting and derusting |

| Shock absorber spring strengthening treatment-Shot balsting |

Manual sandblasting machine, automatic sandblasting machine, open sandblasting machine & sandblasting room

PACKAGE OF CERAMIC BEADS

PACKAGE 1: 25kgs /Barrel+Pallet

PACKAGE 2: 12.5kgs/Barrel, 2 barrels / Paper carton+Pallet

![]()