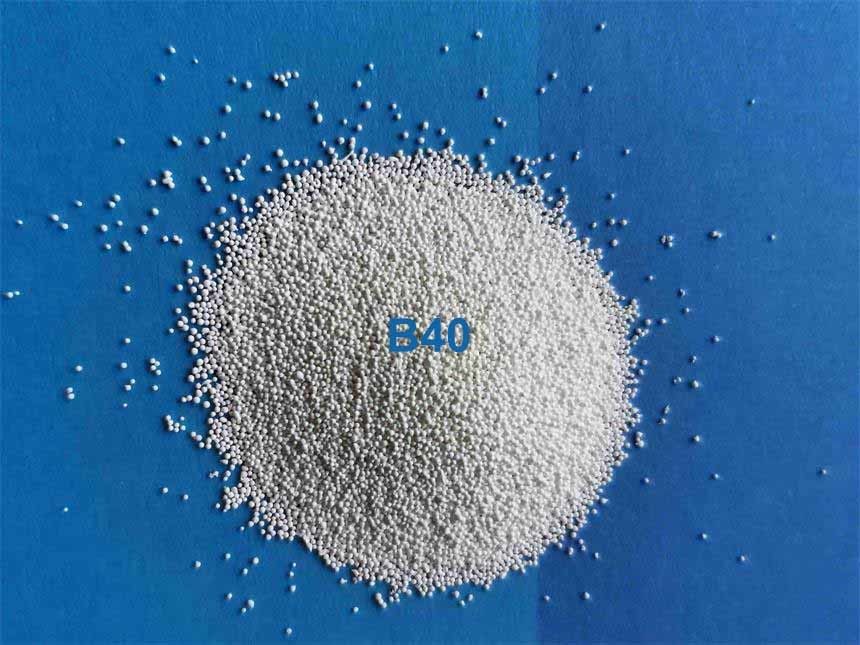

Zero Ferrous Contamination Ceramic Bead Blasting Zirconium Silicate B40

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kg barrel+pallet or 2*12.5kg barrel + Pallet |

| Delivery Time: | Within 3-5 days after order Confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 3000 MTS Per Year |

|

Detail Information |

|||

| Commodity: | Ceramic Bead Blasting Meida | Product Name: | Ceramic Beads |

|---|---|---|---|

| Application: | Blasting Media | Bulk Density: | 2.30 G/cm3 |

| Particle Range: | 0-850 μm | Specification: | B20-B505 |

| Vicker Hardness: | 700HV | Sphericity: | ≥ 80% |

| Highlight: | abrasive media blasting,low dust blasting media |

||

Product Description

Ceramic Bead Blasting B40 250-425μm for Tire- Mold Cleaning

1. Product Description of Ceramic Bead Blasting

Ceramic Beads contains 60-66% ZrO2,so it is also called as zircon sand. Different from glass beads,ceramic

beads has low breakdown rate,there is little dust generated in the blasting process,so it is widely used in many

applications.

Ceramic beads replace glass beads where clean working condition is required. Ceramic beads B40,B60,B120,

B170,B205 is the most popular specification in actual applications.

2. The Main Technical Data of Ceramic Bead Blasting

| Commodity Name | Ceramic Blasting Beads |

| Chemical Index | ZrO2 60-66% SiO2 25-30% Al2O3 7-13% |

| Particle Size | B20:0.600-0.850mm |

| B30:0.425-0.600mm | |

| B40:0.250-0.425mm | |

| B60:0.150-0.300mm | |

| B80:0.125-0.212mm | |

| B100:0.106-0.180mm | |

| B120:0.063-0.125mm | |

| B150:0.000-0.125mm | |

| B170:0.045-0.090mm | |

| B205: 0.000-0.063mm | |

| B400: 0.030-0.063mm | |

| B505: 0.010-0.030mm | |

| Vickers Hardness | ≥700 HV |

| True Specific Gravity | ≥3.85 g/cm3 |

| Bulk Density | ≥2.3g/cm3 |

3. The advantages of Ceramic Bead Blasting

More Consistent Blasting Effect;

Longer service life;

No hidden danger of Silicosis;

No Contamination to the treated work-pieces;

Little damage to the blasting equipment;

4. Main Applications of Ceramic Bead Blasting:

B20&B30 for Metal Surface Finish;

B40 for mold-cleaning of glass bottle;

B60 for surface finish of stainless steel;

B120 for surface finish of glof club and golf head;

B170&B205 for metal case of mobile phone.

![]()

5. Why choose us?

Professional manufacturers of ceramic beads,annual output is over 3000mts;

Higher sphericity and more consistent blasting effect;

Advanced blow-cleaning technology,working normally in wet weather;

Products has exported to USA,Canada,Japan,Vietnam,South Korea,Philippines, Indonesia,Europe,etc.

The stable supplier of Samsung,Foxconn etc.

Prompt reply,competitive price and diverse services;