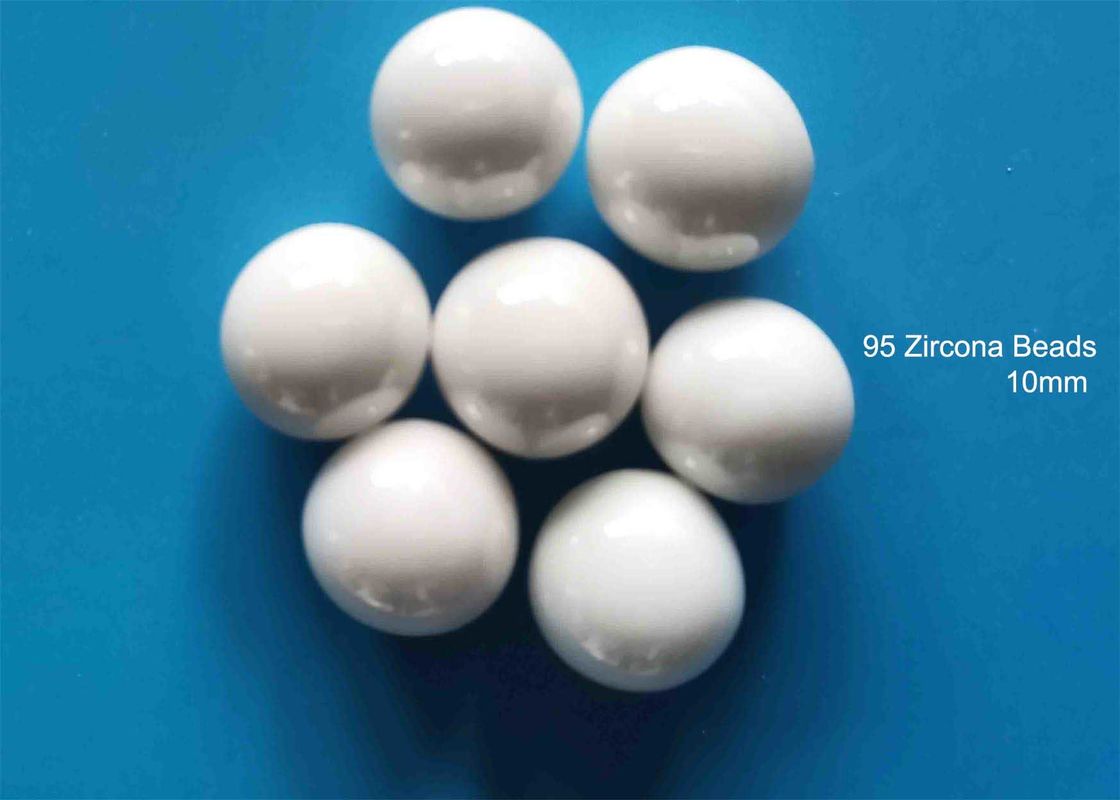

Durable Zirconia Ceramic Balls 95 Yttrium Stabilized For High Viscosity Materials

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | 0.1-50mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | 25KG |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kg barrel + Pallet |

| Delivery Time: | Within 1-3 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 200mt |

|

Detail Information |

|||

| Commodity: | 95 Yttrium Stabilized Zirconia Beads | Product Name: | 95 Zirconia Beads |

|---|---|---|---|

| Application: | Grinding Media | Process: | Sintering |

| Shape: | Round Solid Ball | Bulk Density: | 3.7g/cm3 |

| True Gravity: | ≥6.0 G/cm3 | Vicker Hardness: | ≥1100 HV |

| Highlight: | zirconium oxide beads,zirconium oxide balls,zirconia ceramic balls |

||

Product Description

Most Durable 95 Yttrium Stabilized Zirconia Beads Gringding Media 0.1-50mm For High Viscosity Materials

1. Product Description of 95 Yttrium Stabilized Zirconia Beads

95 Yttrium Stablized Zirconia beads is also called as 95 zirconia beads,it selects the mircon or sub-nanometer

zirconia powder as raw material,sintered by medium-high temperture.It has the characteristics of high grinding

efficiency,low abrasion rate,good sphericity and chemical stability,no contamination to the treated materials.

2. Main Technical Data of 95 Zirconia Beads :

| Commodity | Typical Chemical Index | Main Physical Index |

| 95 Zirconia Beads | ZrO2 ≥95% | True Gravity ≥6.0g/cm3 |

| Y2O3 ≥4.5% | Bulk Density ≥3.7g/cm3 | |

| Others ≤0.5% | Vicker Hardness ≥1100 HV | |

| sintering process | compressive strength ≥2.0KN (Φ2mm) |

| 95 Zirconia Beads Specification | |||

| Φ0.1-0.2mm | Φ0.2-0.3mm | Φ0.3-0.4mm | Φ0.4-0.6mm |

| Φ0.6-0.8mm | Φ0.8-1.0mm | Φ1.0-1.2mm | Φ1.2-1.4mm |

| Φ1.4-1.6mm | Φ1.6-1.8mm | Φ1.8-2.0mm | Φ2.0-2.2mm |

| Φ2.2-2.4mm | Φ2.4-2.6mm | Φ2.6-2.8mm | Φ2.8-3.0mm |

| Φ4mm | Φ5mm | Φ6mm | Φ7mm |

| Φ8mm | Φ9mm | Φ10mm | Φ12mm |

| Φ15mm | Φ17mm | Φ20mm | Φ25mm |

| Φ30mm | Φ40mm | Φ45mm | Φ50mm |

| Special Specification can be customized | |||

3. Why 95 zirconia Beads is one higher efficiency grinding media?

The specific gravity of 95 zirconia beads is almost 1.6 times as the one of zirconium silicate beads, then it will

provide a large impact energy under the same grinding conditions, greatly improving the grinding efficiency,

reducing the grinding times and cycle times,finally save the grinding cost.

Therefore 95 zirconia beads is one higher efficiency grinding media.

4. Main Applications of 95 Yttrium Stabilized Zirconia Beads

Ultrafine grinding for ink, paint, coating, dye etc;

Ultrafine grinding for magnetic materials and nanomaterials;

Ultrafine grinding for pharmaceutical , cosmetics etc.

![]()

5. Applicable Equipment:

Rod pin horizontal sand mill;

Turbine horizontal sand mill;

Profiled disc sand mill;

Ring - sand mill;

Centrifugal sand mill;

Basket sand mill;

Nano sand mill etc.