Automatic Sandblasting Machine Ceramic Bead Blasting B100 Surface Finish For 3C Products

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kg barrel+pallet or 2*12.5kg barrel+ paper carton box + pallet |

| Delivery Time: | 3-5 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 200mts per month |

|

Detail Information |

|||

| Vicker Hardness: | 700 HV | Applicable Equipment: | Automatic Sandblasting Machine |

|---|---|---|---|

| Product Name: | Ceramic Blasting Media | Commodity: | Ceramic Blasting Beads |

| Bulk Density: | 2.3 G/cm3 | True Gravity: | 3.85 G/cm3 |

| Main Material: | 60-66% ZrO2 | Shape: | Solid Round Ball |

| Highlight: | low dust blasting media,ceramic cleaning media |

||

Product Description

Ceramic Blasting Beads B100 Size 0.106-0.180 mm used in Automatic sandblasting machine

- Description

Ceramic Beads is produced in ore furnace by smelting zirconia sand and little aluminium oxide, and blow into micro beads, sizes from B20-B505.

Cearmic beads is with higher cost performance and can be recycled for many time.

Comparing with the glass beads, ceramic beads have higher cleanliness, it can prolong the service life of 20-30 times.

Comparing with the steel shot, it has better smoothness, and 3-5 times longer working life. It can reduce the refueling times and improve the work efficiency.

- Chemical Index:

| ZrO2 | 60-66% |

| SiO2 | 25-30% |

| Al2O3 | 7-13% |

- Physical Index

| Processing | Melting |

| Bulk Density | 2.3g/cm3 |

| True Specific Gravity | 3.97 g/cm3 |

|

Vickers Hardness |

700 kg /mm2 |

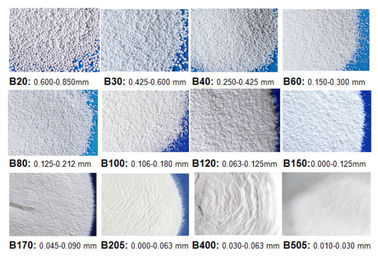

- Sizes

| B20 | 0.600-0.850 mm |

| B30 | 0.425-0.600 mm |

| B40 | 0.250-0.425 mm |

| B60 | 0.150-0.300 mm |

| B80 | 0.125-0.212 mm |

| B100 | 0.106-0.180 mm |

| B120 | 0.063-0.125mm |

| B150 | 0.000-0.125mm |

| B170 | 0.045-0.090 mm |

| B205 | 0.000-0.063 mm |

| B400 | 0.030-0.063 mm |

| B505 | 0.010-0.030 mm |

- Application

1) 3C products - Sandblasting Finishing

2) Aerospace industry-Blasting finishing

3) Automotive industry-sandblasting reinforcement

4) Kitchen Industry-Sandblasting finishing

5) Machinery, Medical Instrument - Sandblast finishing

6) Casting, forging , welded, heat-treated parts - Sandblast Cleaning

7) Pipeline - Sandblast Cleaning

8) Molds - Sandblast cleaning

9) Electroplating, painting, anode-Surface Pre-treatment.

10) Hardware parts - Sandblast to improve lubrication conditions.

- Applicable Equipment

Ceramic beads can be used in below sandblasting machine:

![]()

1. Manual sandblasting machine

2. Automatic sandblasting machine

3. Open sandblasting machine

4. Sandblasting room

If you need more details of ceramic beads, or any application confusions or questions, please don't hesitate to contact me.

You will get fast response and professional advise.