60HRC Ceramic Polishing Media B120 63 - 125μM Zirconia Sand For Golf Clubs

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25 KG (12L)Barrel + Pallet; 2*12.5 KG Barrel+ Carton Box+ Pallet |

| Delivery Time: | Within 3-5 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 3000 MTS Per Year |

|

Detail Information |

|||

| Commodity: | Ceramic Beads | Product Name: | Zirconia Sand |

|---|---|---|---|

| Application: | Blasting Media Or Shot Peening | Shape: | Round Solid Ball |

| Mohs Hardness: | 8 | Bulk Density: | 2.3 G/cm3 |

| True Gravity: | 3.85g/cm3 | Specification: | B120 63-125μm |

| Highlight: | abrasive media blasting,ceramic cleaning media |

||

Product Description

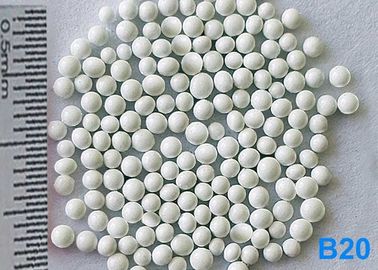

60HRC Ceramic Bead Blasting B120 63-125μm Zirconia Sand for Golf Clubs, Titanium Alloy

1. Product Description of Ceramic Bead Blasting

Ceramic bead selects the high quality zircon sand as main raw material,then fused in an electric furnace under high temperature,then made into different sizes through one special technology process.

2. Main technical Data of Ceramic Bead Blasting

| Main Index of Ceramic Bead Blasting | ||

| ZrO2 | SiO2 | Al2O3 |

| 60-66% | 25-30% | 7-13% |

| Vicker Hardness | True Specific Gravity | Bulk Density |

| ≥700 HV | ≥3.85 g/cm3 | 2.3g/cm3 |

| Available Specification | |

| B20 | B30 |

| 600-850μm | 425-600μm |

| B40 | B60 |

| 250-425μm | 125-250μm |

| B80 | B100 |

| 180-250μm | 125-180μm |

| B120 | B170 |

| 63-125μm | 45-90μm |

| B205 | B400 |

| 0-63μm | 30-63μm |

| Special Specification can be customized | |

3. Main Features of Ceramic Bead Blasting

High hardness, good elasticity;

Long service life and higher efficiency;

Low breakdown rate,more consistent blasting effect;

No ferrous contamination to the workpieces;

No Hidden dangers of silicosis.

4. Main Applications of Ceramic Bead Blasting

Surface finish for 3C products,medical instruments,golf clubs

Surface cleaning for glass molds,tire molds,plastic molds

Deburring for circuit board in electric industry

Surface cleaning for the inner and outter wall of pipelines

Shot peening in automotive and aerospace industries

![]()

5. Which kind of blasting media can be replaced by Ceramic Beads?

Ceramic beads can replace glass beads where one cleaner work condition is required or replce steel shot

where ferrous contamination is not allowed.

Ceramic beads has medium density,which can make up the lower and upper limit of steel shot and glass beads

in blasting effect.

Compared with glass beads,ceramic beads will achieve more shinny visual effect and more consistent blasting

effect.

Compared with steel shot,ceramic beads will also provide one shinny visual effect , no discoloration.

6. Why Choose Us?

Higher clearliness

Our ceramic bead are screened more than six times and blow-cleaning under high temperature,which provides

higher clearliness and ensures it to be work normally in humid weather;

More concentrated particle size distribution

B170(0.045-0.090μm),B400(0.030-0.063μm) is more concentrated than the other one(0-0.063μm) from other company,

which will achieve better blasting effect.

More competitive price

Our plant is located in mountain area,which provides lower cost in environmental protection and workers’ salary,then

the product price is more competitive than the one of other plants.

More flexible corporation model

No matter you are the distributor or final users,we will provide the more flexible payment term and corporation model.