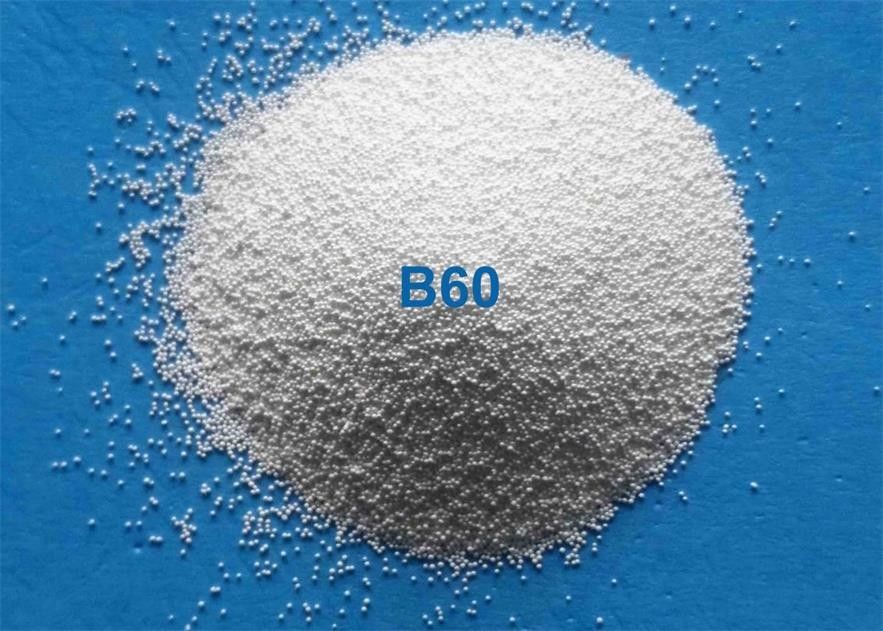

B60 125-250 μM Ceramic Bead Blasting Media Zirconia Sand For Surface Finish In Stainless Steel

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25 KG (12L)Barrel + Pallet; 2*12.5 KG Barrel+ Carton Box+ Pallet |

| Delivery Time: | Within 3-5 days after order confirmed |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 3000 MTS Per Year |

|

Detail Information |

|||

| Commodity: | Ceramic Bead | Product Name: | Zirconia Sand |

|---|---|---|---|

| Application: | Blasting Media Or Shot Peening | Shape: | Round Solid Ball |

| Wear Rate: | 0.5-1.0 KG/Hour | Bulk Density: | 2.3 G/cm3 |

| True Gravity: | 3.85g/cm3 | Main Chemical: | 60-66% ZrO2 |

| Highlight: | abrasive media blasting,ceramic cleaning media |

||

Product Description

Ceramic Bead Blasting Media Zirconia Sand B60 125-250 μm for Surface Finish in Stainless steel 304 & 316L

1. Product Description of Ceramic Beads

Ceramic bead is one round solid blasting media,it is able to replace glass beads when sandblasting for

metal surface and plastic parts.

Compared with glass beads,ceramic beads is not easy to be broken and little dust generated in blasting

process,it will provide one clean working condition as well as more consistent visual effect after blasted.

It has lower wear rate at 0.5-1.0kg per hour.Therefore it is also one economic and high efficient blasting

media.

2. Main Technical Data of Ceramic Beads

| Item | Ceramic Beads |

| Chemical Index | ZrO2 60-66% SiO2 25-30% Al2O3 7-13% |

| Processing Method | Melting |

| Vickers Hardness | ≥700 HV |

| True Specific Gravity | ≥3.85 g/cm3 |

| Bulk Density | ≥2.3g/cm3 |

| Usage | Blasting Media & Shot Peening |

| Available Specification | |

| B20 | B30 |

| 600-850μm | 425-600μm |

| B40 | B60 |

| 250-425μm | 125-250μm |

| B80 | B100 |

| 180-250μm | 125-180μm |

| B120 | B170 |

| 63-125μm | 45-90μm |

| B205 | B400 |

| 0-63μm | 30-63μm |

| Special Specification can be customized | |

3. Product Package of Ceramic Bead Blasting Media

![]()

4. Main Applications of Ceramic Beads

Surface Finish for metal surface and built-in parts for 3C products as well as the accessories;

Surface finish for stainless steel products such as stainless steel 304 & 316L;

Surface cleaning in pipelines,mold cleaning in glass bottle,die casting,tire industries;

Surface strengthening in aviation and automotive industries such as titanium alloys components and

turbine blade.

5. Precautions When Using Ceramic Beads for the first time

Please kindly open 1/3 to 1/2 vest of dust collector when using ceramic bead for the first time,because ceramic

beads need the wind to be recycled. This is different from glass beads, when using galss beads,the vest of dust

collector is sealed completely.

6. Why choose us?

Higher clearliness

Our ceramic bead are screened more than six times and blow-cleaning under high temperature,which provides

higher clearliness and ensures it to be work normally in humid weather;

More concentrated particle size distribution

B170(0.045-0.090μm),B400(0.030-0.063μm) is more concentrated than the other one(0-0.063μm) from other

company,which will achieve better blasting effect.

More competitive price

Our plant is located in mountain area,which provides lower cost in environmental protection and workers’ salary,

then the product price is more competitive than the one of other plants.

More flexible corporation model

No matter you are the distributor or final users,we will provide the more flexible payment term and corporation model.