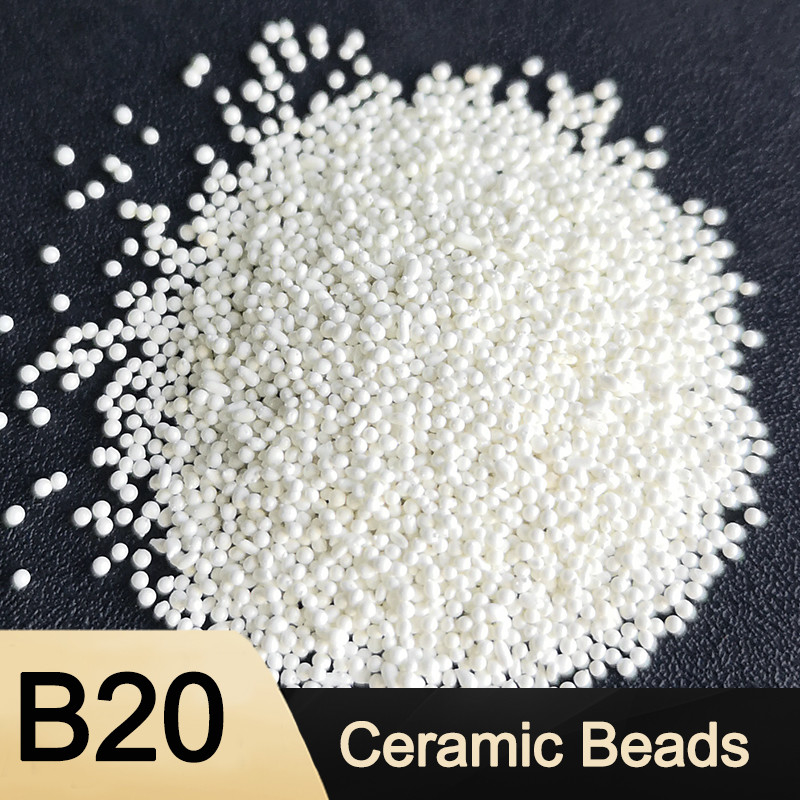

Surface Finish spherical Ceramic Bead Blasting Media B20 Size 600 - 850 μm

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20, B30,B40, B60, B80,B100, B120, B170, B205, B400 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 12.5kgs/barrel, 25kgs (2 barrels)/paper carton, or 25kgs barrels +pallet |

| Delivery Time: | 5-10 days |

| Supply Ability: | 1500mt per year |

|

Detail Information |

|||

| Commodity Name: | Ceramic Microbeads Blasting Media | Chemical Index: | ZrO2 60-68%, SiO2 25-30%, Al2O3 7-13% |

|---|---|---|---|

| Manufacturing Process: | Melting Method | Bulk Density: | 2.3g.cm3 |

| True Density: | 3.85g/cm3 | Hardness: | 700HV |

| Package: | 2*12.5kgs Barrels In Paper Cartons Or 25kgs Barrels +pallet | ||

| Highlight: | low dust blasting media,ceramic cleaning media |

||

Product Description

Surface finish Ceramic beads blasting media B20 size 600-850 μm

DESCRIPTION OF CERAMIC BEADS BLASTING MEDIA

Ceramic beads is round blasting and shot peening media , high tech abrasive agent used in aviation and Aerospace industry.

Ceramic beads quality meets standard of SAE J1830 and SAE AMS 2431/7

Application covering Deburring, Surface Finishing, Polishing and Cleaning.

Zhengzhou Zhengtong Abrasive Imp.&Exp. Co., is the main exporter of ceramic beads from China.

SPECIFICATION OF CERAMIC BEADS BLASTING MEDIA

| Chemical Index | ZrO2 | SiO2 | Al2O3 |

| 60-65% | 25-30% | 7-13% | |

| Typical Value | 62.20% | 26.10% | 9.05% |

| Bulk Density | 2.3g/cm3 | ||

| Specific Density | 3.85g/cm3 | ||

| Vickers Hardness | 700HV | ||

Sizes

| B20 | B30 | B40 | B60 |

| 600-850µm | 425-6000µm | 0250-425µm | 125-250µm |

| B80 | B120 | B170 | B205 |

| 180-250µm | 63-125µm | 45-90µm | 0-63µm |

Special sizes available against clients’ requirement.

FEATURES OF CERAMIC BEADS BLASTING MEDIA

Surface finish consistency

01 Low breakdown

With features of less abrasive breakdown and almost no dust generation which in turn results in a cleaner working environment and better operator visibility

Comparing with glass beads, ceramic bears is of low breakdown rates up to 15:1 , thus enables it repeatable and consistent result to be achieved.

02 Narrow particle size distribution

The more centralized granularity can make the objects surface more uniform, and softer view in blasting process.

Contrast of Ceramic bead, glass beads and steel shot

| Index | Ceramic beads | Glass beads | Steel shot |

| Main components | ZrO2+SiO2 | SiO2+NaO2 | C+Si+Mn+S+P |

| Vickers hardness | ≈700HV | ≈560HV | ≈700HV |

| True density | 3.85g/cm³ | 2.6 g/cm³ | 7.8 g/cm³ |

| Particle size interval | 0.04-0.85mm | 0.045-0.85mm | 0.05-0.60mm |

| Particle shape | spherical | spherical | rounded corner |

| Dust pollution | very little | much | little |

| Metal pollution | no | no | yes |

| Number of cycles | multiple times | 1-2times | multiple times |

| service life | long | Low,1/20 of ceramic bead | long |

| power consumption | Low | Low | High |

| Equipment wear | Low | Low | High |

| Sandblasting effect | High finish, non-discoloration of workpiece | high finish, white glaze, |

low finish, |

APPLICATION OF CERAMIC BEADS BLASTING MEDIA

- In Sandblasting

1) 3C products - Sandblasting Finishing

Alloy shell, middle frame and built-in parts of computers, mobile phones, cameras, etc. - sandblasting finishing

Clean burrs to form film-light decorative or fine reflective surface, on alloy workpiece such as mobile phone to achieve different reflection or matte.

2) Kitchen Industry-Sandblasting finishing

Stainless steel cutlery and kitchen utensils sandblasting finishing

3) Golf club - Sandblasting finishing

Golf club & ball head alloy surface treatment Sandblasting finishing

4) Casting and forging parts, welded parts, heat-treated parts - Sandblast Cleaning

Clean all the dirt on the surface of the alloy workpiece, micro burrs, improve the flatness and smoothness of the workpiece, and expose to uniform metallic color, achieving smooth and non-reflective requirements on surface.

5) Pipeline - Sandblast Cleaning

Metal pipes such as copper pipes and steel pipes are cleaned and polished on the inner and outer walls.

6) Molds - Sandblast cleaning

Cleaning of molds of glass bottles, tires, etc., rust, dirt and impurities.

7) Electroplating, painting, anode-Surface Pretreatment

Electroplating, painting, anode, Teflon, rubber, plastic, traversing, metal, spray welding, gold plating, titanium plating, etc., to remove dirt and increase product surface adhesion.

8) Hardware parts - Sandblasting to improve lubrication conditions

It can produce uniform and fine uneven surface on the surface of the part, so that the lubricating oil can be stored, improve the lubrication condition and reduce the noise.

- In shot peening

1) Aerospace industry-Shot Peening

Suitable for aerospace engine components, aircraft landing gear, gear transmissions, aero-engine blades, aircraft wing-shot peening

2) Automotive industry-Sandblasting reinforcement/ Shot Peening

Suitable for gearbox gears, automotive aluminum hubs, piston components/shock absorbers, engine crankshaft sandblasting reinforcement/shot peening

3) Machinery, Medical Instrument - Sandblast finishing/shot peening

The overall sandblasting and polishing, finishing, restore the natural color of the metal, enhance the visual effect and texture, and also shot peening reinforcement to improve its worklife.

![]()

APPLICABLE EQUIPMENT

Overhead conveyor blast machines

Tumble belt blast machines

Rotary tab le blast machines

Roller conveyor blast machines

Compressed air sandblasters

Sandblasting room