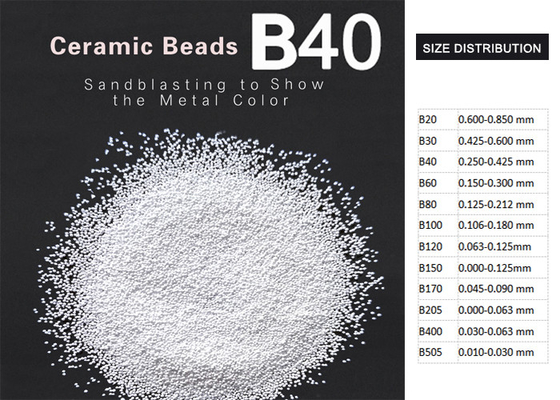

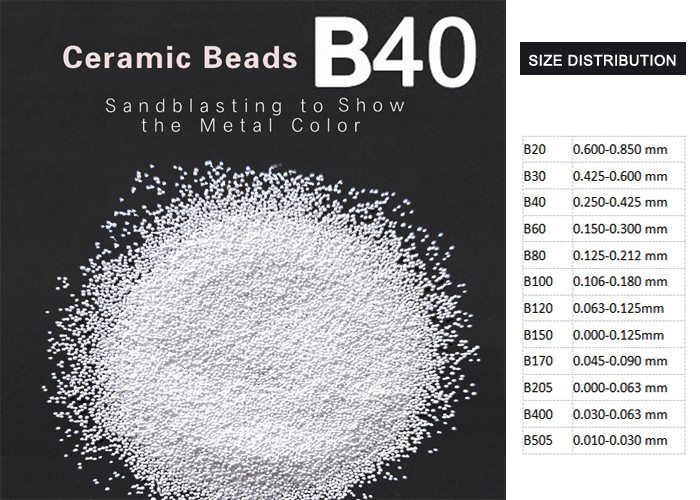

B40, B60 ZrO2 62% Ceramic Bead Blasting Molds Cleaning 700HV Hardness

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 12.5kgs/barrel, 25kgs (2 barrels)/paper carton, or 25kgs barrels +pallet |

| Delivery Time: | 5-10 days |

| Supply Ability: | 1500mt per year |

|

Detail Information |

|||

| Commodity Name: | Ceramic Beads Blasting Media | Chemical Index: | ZrO2 60-66%, SiO2 25-30%, Al2O3 7-13% |

|---|---|---|---|

| Manufacturing Process: | Melting Method | Bulk Density: | 2.3g.cm3 |

| True Density: | 3.85g/cm3 | Hardness: | 700HV |

| Package: | 25kgs Paper Cartons Or 25kgs Barrels +pallet | ||

| Highlight: | abrasive media blasting,ceramic cleaning media |

||

Product Description

Ceramic beads blasting media B40,B60 of ZrO2 62% for molds cleaning

DESCRIPTION

Ceramic beads blasting media is made of mineral oxides of zirconia sand through electro fusion in ore furnace. It has a fine internal structure of zirconium crystals in a glassy silicon dioxide cover, and this structure leads the ceramic beads of high density and high shock resistance.

Ceramic Beads are extremely tough and fracture resistant, ensuring consistent surface finishes.

SPECIFICATION

Manufacturing process: Melting method

| ZrO2 | SiO2 | Al2O3 | Other |

| 60-66%, | 25-30% max. | 7-13% max. | 5-8% |

| Color | Bulk Density | True Specific Density | Vickers Hardness |

| White | 2.3g/cm3 | 3.85g/cm3 | 700 HV |

Sizes

| B20 | B30 | B40 | B60 |

| 600-850µm | 425-6000µm | 0250-425µm | 125-250µm |

| B80 | B120 | B170 | B205 |

| 180-250µm | 63-125µm | 45-90µm | 0-63µm |

Special sizes available against clients’ requirement.

FEATURES

- Very high shock resistance: the beads remain round for a long period, not break.

- Very low dust formation, safe for workers

- With lower breakdown rate ceramic beads will reproduce more consistent surface finishes over long production runs.

- A steady roughness, not easy to deform

- No metal pollution

- Less waste disposal

APPLICATION

- Molds Cleaning

Removal of carbon deposits and other impurities from glass making and rubber tire molds, without damaging the surface or critical edges. Deburring thin gaskets.

- Surface finishing

Cleaning, sanitizing and surface finishing of fabricated stainless steel items for food and pharmaceutical industries. Blasting gives stainless steel a satin grey touch

Medical implant and instrument surface finishing.

Work pieces blasted with ceramic beads are a lot less prone to fingerprints and other handling stains than those blasted with glass beads and stay looking good a lot longer.

![]()

APPLICABLE EQUIPMENT

Suitable sand blasting machine:

Manual type series:

Manual closed type blasting machine, manual cart rotary blasting machine, double gun double station manual blasting machine, manual (automatic) roller dual-purpose blasting machine, manual closed pressure

Automatic series of sand blasting machine:

Automatic closed pressure blasting machine, automatic conveying type blasting machine, crawler type blasting machine, automatic turntable blasting machine, automatic turntable continuous pressure blasting machine, automatic conveying

Open type series of sand blasting machine:

Crankshaft inner wall automatic sand blasting machine

Blasting room series:

Pneumatic conveying type blasting room, mechanical conveying type blasting room, etc.