Ceramic Media Blasting Materials , Fused Abrasive Blasting Media 700HV Hardness

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20, B30,B40, B60, B80,B100, B120, B170, B205, B400 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiation |

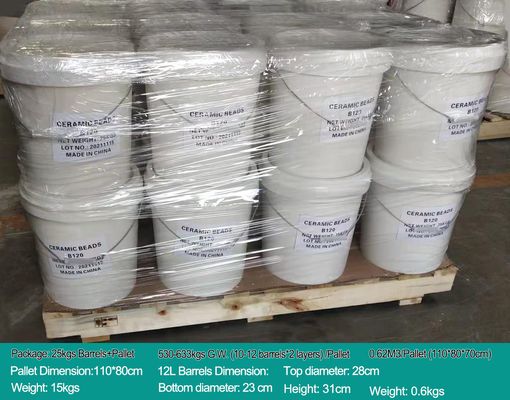

| Packaging Details: | 12.5kgs/barrel, 25kgs (2 barrels)/paper carton, or 25kgs barrels +pallet |

| Delivery Time: | 5-10 days |

| Supply Ability: | 1500mt per year |

|

Detail Information |

|||

| Commodity Name: | Ceramic Beads Blasting Media | Chemical Index: | ZrO2 60-66%, SiO2 25-30%, Al2O3 7-13% |

|---|---|---|---|

| Manufacturing Process: | Melting Method | Bulk Density: | 2.3g.cm3 |

| True Density: | 3.85g/cm3 | Hardness: | 700HV |

| Package: | 25kgs Paper Cartons Or 25kgs Barrels +pallet | ||

| Highlight: | abrasive media blasting,low dust blasting media |

||

Product Description

Ceramic beads blasting media B20, B30 Hardness 700HV

1. Discription of ceramic beads blasting meida

Ceramic Beads blasting media is manufactured by electric fusion of zirconium oxides powder.

The internal structure is made up of a crystalline ceramic phase bonded by an amorphous silica phase resulting in high impact properties coupled with good hardness. It is spherical and of smooth surface, much lower roughness than glass beads, leading beautiful satin shine finish on the blasting work piece and easier to clean after sand blasting.

2. Specification of ceramic beads blasting meida

| Chemical Index | ZrO2 | SiO2 | Al2O3 |

| 60-65% | 25-30% | 7-13% | |

| Typical Value | 62.20% | 26.10% | 9.05% |

| Bulk Density | 2.3g/cm3 | ||

| Specific Density | 3.85g/cm3 | ||

| Vickers Hardness | 700HV | ||

Sizes

| B20 | B30 | B40 | B60 |

| 600-850µm | 425-600µm | 0250-425µm | 125-250µm |

| B80 | B120 | B170 | B205 |

| 180-250µm | 63-125µm | 45-90µm | 0-63µm |

Special sizes available against clients’ requirement.

3. Features of ceramic beads blasting meida

1. Spherical smooth surface, blasting with ceramic beads can get satin finish surface, roughness less than 1.0 micron can be achieved.

2. Not distort or change dimensions of most parts during blasting

3. Durability- Working life of Ceramic beads can be up to dozens of times longer than glass beads.

4. Easy to clean after sand blasting

4. Application of ceramic beads blasting meida

Ceramic Beads blasting media is used for surface cleaning of

Rubber and plastic molds cleaning,

Castings and forgings sandblasting for surface satin finish

Mechanical parts like boiler and heat exchanger parts to release stresses

Stainless steel surface treatment in the food and pharmaceutical industries

Shot peening and peen forming of components, particularly in the aerospace industry.

5. Application of ceramic beads blasting meida

Used in airless and compressed air blasting equipment, both wet and dry.

Notes:

When used in airless blasting equipment, sufficient media coverage of the blades must be maintained to avoid excessive media breakdown rates.

6. Production Process of ceramic beads blasting meida

![]()

7. Our Service

Free Samples -1kgs

Different blasting workpieces, Different requirements for ceramic beads.

Our factory can provide consult solution, suggest the ceramic beads sizes according to the workpiece you handle and provide 1kgs ceramic beads samples for free.

OEM customize same ceramic beads with your samples or requirements.

Our factory has our own test lab., with high precision chemical and particle size detection instruments. You can send ceramic beads samples, then we will test and analysis it and customize same ceramic beads with your samples or according to your customer requirements.

Quality Guarantee

Guarantee our ceramic beads has no quality problems, and in case any problems are found,

We accept return and/or exchange.

8. Contact us

Caroline Cui

Zhengzhou Zhengtong Abrasive Imp.&Exp. Co., Ltd

Address: Ximazhuang, Liuzhai Town, Xinmi City, Henan, China

Tel.:+371 86592608

Mob.: +86 15003865330

Email: caroline@zzztabrasive.com