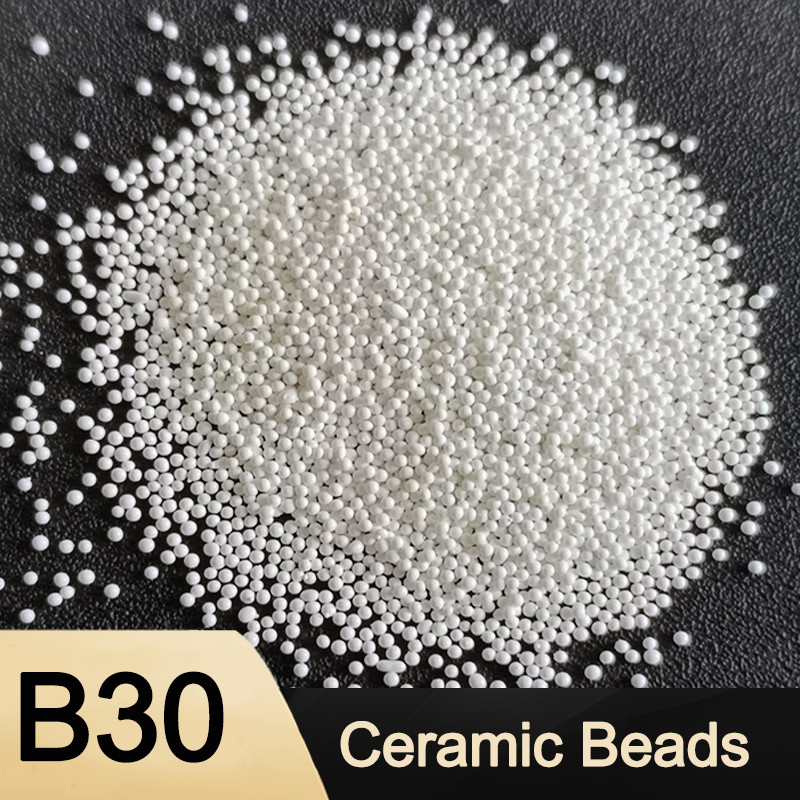

ZrO2 60% Ceramic Bead Blasting B30 For 3C Products Sandblasting Deblur

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | B20-B505 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100KGS |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 12.5kgs/barrel, 25kgs (2 barrels)/paper carton, or 25kgs barrels +pallet |

| Delivery Time: | 5-10 days |

| Supply Ability: | 1500mt per year |

|

Detail Information |

|||

| Commodity Name: | Ceramic Beads Blasting Media | Chemical Index: | ZrO2 60-66%, SiO2 25-30%, Al2O3 7-13% |

|---|---|---|---|

| Manufacturing Process: | Melting Method | Bulk Density: | 2.3g.cm3 |

| True Density: | 3.85g/cm3 | Hardness: | 700HV |

| Package: | 25kgs Paper Cartons Or 25kgs Barrels +pallet | ||

| Highlight: | low dust blasting media,ceramic cleaning media |

||

Product Description

ZrO2 60% Ceramic Bead Blasting B30 for 3C products sandblasting deblur

Description of ceramic beads sandblasting media

The ceramic bead blasting also called ceramic beads, ceramic blasting beads, or Zirconia ceramic blasting media, is made from zirconium sand, melting and blending in the high temperature mine heat furnace, then made to micro beads by special technology, its features are high hardness, good elasticity, high gloss and high impact strength. Ceramic blasting beads mainly used for debluring in mobile phone middle frames and other 3C products, also in molds cleaning, surface pretreatment and shot peening in aerospace industry, automotive industry and medical instrument.

Specification of ceramic beads sandblasting media

Manufacturing process: Melting method

| ZrO2 | SiO2 | Al2O3 | Other |

| 60-66%, | 25-30% max. | 7-13% max. | 5-8% |

| Color | Bulk Density | True Specific Density | Vickers Hardness |

| White | 2.3g/cm3 | 3.85g/cm3 | 700 HV |

Sizes

| B20 | B30 | B40 | B60 |

| 600-850µm | 425-6000µm | 0250-425µm | 125-250µm |

| B80 | B120 | B170 | B205 |

| 180-250µm | 63-125µm | 45-90µm | 0-63µm |

Special sizes available against clients’ requirement.

Features of ceramic beads sandblasting media

High efficiency

With high hardness, long life and good elasticity, suitable for the complicated structure,without damage to the surface of the workpiece, eliminate the stress and improve the fatigue life of the workpiece.

High cost performance

Compared to glass beads, it has higher cleanliness, can prolong the service life 30-50 times. Compared to steel beads, it has superior smoothness, can prolong life 3-5 times. It ‘s also recyclable,and can reduce the refueling times, improve working efficiency.

Environmental protection

Not easy to break during sandblasting process, no dust, clean, and no hidden danger of silicosis, it is harmless to the human body.

Application of ceramic beads sandblasting media

SANDBLASTING

1) 3C products - Sandblasting Finishing

Alloy shell, middle frame and built-in parts of computers, mobile phones, cameras, etc. - sandblasting finishing

Clean burrs to form film-light decorative or fine reflective surface, on alloy workpiece such as mobile phone to achieve different reflection or matte.

2) Golf club - Sandblasting finishing

Golf club, ball head alloy surface sandblasting finish

3) Kitchen Industry-Sandblasting finishing

Stainless steel cutlery and kitchen utensils sandblasting finishing

4) Machinery, Medical Instrument - Sandblast finishing/shot peening

The overall sandblasting and polishing, finishing, restore the natural color of the metal, enhance the visual effect and texture, and also shot peening reinforcement to improve its worklife.

5) Casting and forging parts, welded parts, heat-treated parts - Sandblast Cleaning

Clean all the dirt on the surface of the alloy workpiece, micro burrs, improve the flatness and smoothness of the workpiece, and expose to uniform metallic color, achieving smooth and non-reflective requirements on surface.

6) Pipeline - Sandblast Cleaning

Metal pipes such as copper pipes and steel pipes are cleaned and polished on the inner and outer walls.

7) Molds - Sandblast cleaning

Cleaning of molds of glass bottles, tires, etc., rust, dirt and impurities.

8) Electroplating, painting, anode-Surface Pretreatment

Electroplating, painting, anode, Teflon, rubber, plastic, traversing, metal, spray welding, gold plating, titanium plating, etc., to remove dirt and increase product surface adhesion.

10) Hardware parts - Sandblasting to improve lubrication conditions

It can produce uniform and fine uneven surface on the surface of the part, so that the lubricating oil can be stored, improve the lubrication condition and reduce the noise.

![]()

SHOT PEENING

1) Aerospace industry-Shot Peening

Suitable for aerospace engine components, aircraft landing gear, gear transmissions, aero-engine blades, aircraft wing-shot peening

2) Automotive industry-Sandblasting reinforcement/ Shot Peening

Suitable for gearbox gears, automotive aluminum hubs, piston components/shock absorbers, engine crankshaft sandblasting reinforcement/shot peening

3) Machinery, Medical Instrument - Sandblast finishing/shot peening

The overall sandblasting and polishing, finishing, restore the natural color of the metal, enhance the visual effect and texture, and also shot peening reinforcement to improve its worklife.

Applicable equipments

- In sandblasting

Manual sandblasting machine

Automatic sandblasting machine

Open type sandblasting machine

Sandblasting machine room

- In shot peening /shot blasting

Pneumatic shot blasting machine

Centrifugal shot blasting machine

CNC shot peening equipment

Wet shot blasting equipment

Contact us

Caroline Cui

Zhengzhou Zhengtong Abrasive Imp.&Exp. Co., Ltd

Address: Ximazhuang, Liuzhai Town, Xinmi City, Henan, China

Tel.:+371 86592608

Mob.: +86 15003865330

Email: caroline@zzztabrasive.com