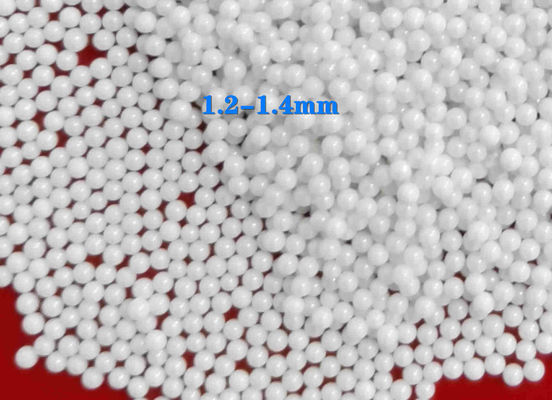

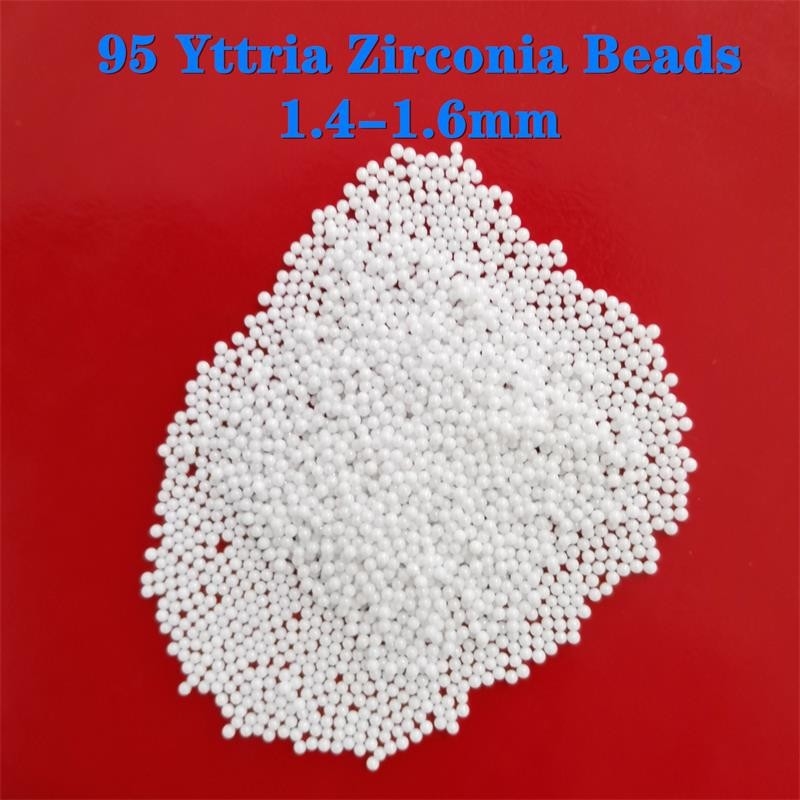

95 Yttria Ceramic Grinding Balls Media Stabilized Zirconia 1.2 - 1.4mm

Product Details:

| Place of Origin: | Zhengzhou |

| Brand Name: | Zhengtong |

| Certification: | N/A |

| Model Number: | 1.2-1.4mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | Negotiable |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kgs Barrels+Pallet |

| Delivery Time: | 2-20 days |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 500mt per Year |

|

Detail Information |

|||

| Product Name: | Yttrium Stabilized Zirconium Oxide Beads | Color: | Shiny White |

|---|---|---|---|

| True Density: | 6.0g/cm3 | Bulk Density: | 3.7g/cm3 |

| Impact Strength: | 2.0KN | Moh's Hardness: | 8-9 |

| Package: | 25kgs Barrels+Pallet | Usage: | Grinding &Dispersion |

| Highlight: | 95 Yttria Stabilized Zirconia,Ceramic Grinding Balls Media,1.4mm Ceramic Grinding Balls |

||

Product Description

1. Product Description

95 Yittria-stabilized zirconia ceramic grinding bead is made of micro zirconia powder by sintering method. It has good roundness, smooth surface, high density and hardness, and it’s perfect ultra-fine grinding media. The Zirconia beads are used for superfine grinding and dispersion of zero pollution, high viscosity,high hardness and so on.

It is applied to the equipments, such as horizontal sand mills,vertical sand mills,basket mills, ball mills and so on.

2. Main technical Data of 95 Zirconia Ceramic Beads

|

Item

|

Data

|

|

Composition

|

ZrO2 95 Min

|

|

Y2O3 4.5 Min

|

|

|

Hardness

|

1100HV

|

|

Mohs |

9

|

|

True density

|

6.00g/cm3

|

|

Bulk density

|

3.7g/cm3

|

|

Compressive Strength |

5500MPa

|

|

Roundness

|

98

|

|

Color

|

White/ivory

|

|

SIZES Φ MM |

||||

|

0.1-0.2 |

0.2-0.3 |

0.3-0.4 |

0.4-0.6 |

0.6-0.8 |

|

0.8-1.0 |

1.0-1.2 |

1.2-1.4 |

1.4-1.6 |

1.6-1.8 |

|

1.8-2.0 |

2.0-2.2 |

2.2-2.4 |

2.4-2.6 |

2.6-2.8 |

|

2.8-3.0 |

4,5,6,7,8,9,10,12,15,17,20,25,30,40,50 |

|||

3. Advantage of ZIrconia Beads

-

High density

-

Very high wear and tear resistance;

-

High stability, acid and alkali-resistance

-

Low contamination of the grinding product, so it is useable for high-grade grinding of pigments,paint and cosmetic products;

-

useable for many types of mills and high energy mills(vertical and horizontal);

-

Low abrasion wear(ppm grade), low harm to the equipment

-

In comparison to ceramic beads made of zirconium silicate, it is no radioactivity and so no contamication of the grinding product and no costly disposal of the beads.

4. Application of 95 Zirconia Beads

-

Grinding of very hard materials, such ad pigments and magnetic coatings;

-

Grinding od pharmaceuticals , food and cosmetics, there is no contamination of the product because of the extremely low wearing rate;

-

Grinding of high quality paints and varnishes, like automotive;

-

It is the best grinding media for basket mills and high efficiency horizontal mills and other equipment;

-

Nano particle size grinding.

![]()